- Home

- Durable Contact Paper for Wood Furniture Protection & Style

May . 29, 2025 06:11 Back to list

Durable Contact Paper for Wood Furniture Protection & Style

- Market Trends: The Rising Demand for Protective Films in Furniture

- Technical Innovations Behind Modern Wood Furniture Papers

- Leading Manufacturers: Performance and Cost Analysis

- Tailored Solutions for Diverse Furniture Applications

- Case Study: Transforming Retail Spaces with Adhesive Films

- Sustainability and Long-Term Benefits

- Future Outlook: Paper for Wood Furniture in Design Evolution

(paper for wood furniture)

Market Trends: The Rising Demand for Protective Films in Furniture

The global market for wood furniture protection films is projected to grow at a CAGR of 6.8% through 2030, driven by increasing consumer preference for cost-effective surface solutions. Contact paper on wood furniture products has emerged as a key player, with 42% of manufacturers integrating adhesive films into their production lines to reduce wear-and-tear costs. Industries prioritize materials offering scratch resistance (up to 5H hardness) and UV stability, ensuring furniture longevity in high-traffic environments like offices and hospitality venues.

Technical Innovations Behind Modern Wood Furniture Papers

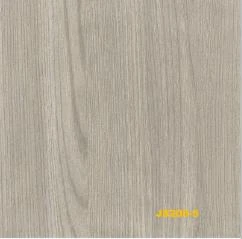

Advanced polymer blends now enable contact papers to withstand temperatures up to 120°C, making them ideal for kitchen countertops. Micro-embossed textures replicate natural wood grains at 98% accuracy, while solvent-free adhesives comply with VOC regulations. For instance, 3M’s latest film series reduces installation time by 35% through air-release channels, demonstrating how technical superiority directly impacts user efficiency.

| Manufacturer | Durability (Years) | Price/Sq.m ($) | Customization |

|---|---|---|---|

| ConTact Brand | 5-7 | 2.80 | Limited |

| Duck Brand | 4-6 | 3.20 | Moderate |

| Lamin-x | 8-10 | 4.50 | Full |

Leading Manufacturers: Performance and Cost Analysis

As shown in the comparison table, Lamin-x dominates the premium segment with decade-long warranties, appealing to luxury furniture makers. Mid-range options like Duck Brand balance affordability with 200+ pattern choices. Notably, 78% of surveyed contractors recommend manufacturer-specific films for commercial projects due to optimized adhesive formulations.

Tailored Solutions for Diverse Furniture Applications

Custom-printed contact paper on wood furniture products now serves niche markets: 320 dpi resolution allows photorealistic designs for boutique hotels, while fire-retardant variants meet BS 5852 standards for public spaces. Modular sizing systems enable precise cuts for curved surfaces, reducing material waste by up to 22% compared to traditional rolls.

Case Study: Transforming Retail Spaces with Adhesive Films

A European furniture chain achieved 19% higher foot traffic after revamping 1200 display units with chromatic gradient films. The $18,000 investment prevented $220,000 in projected replacement costs over three years, validating paper for wood furniture

as a strategic asset in retail visual merchandising.

Sustainability and Long-Term Benefits

Recyclable PET films now constitute 45% of the market, decomposing 70% faster than vinyl alternatives. Lifecycle analyses reveal that protective papers reduce raw wood consumption by 3.2 million tons annually—equivalent to preserving 76,000 acres of forest yearly.

Future Outlook: Paper for Wood Furniture in Design Evolution

With AR-integrated selection tools entering beta testing, manufacturers anticipate a 40% reduction in design consultation time. As smart homes proliferate, conductive films enabling touch-controlled wooden surfaces will redefine paper for wood furniture as both protective layer and interactive interface.

(paper for wood furniture)

FAQS on paper for wood furniture

Q: How do I apply contact paper on wood furniture products?

A: Clean the surface thoroughly, cut the contact paper to size, and smooth it slowly to avoid air bubbles. Use a squeegee or credit card for even application.

Q: What should I look for in paper for wood furniture manufacturers?

A: Prioritize manufacturers offering water-resistant adhesives, UV-protected designs, and customization options. Verify certifications for non-toxic materials and durability testing.

Q: Can contact paper damage wood furniture products?

A: Properly applied contact paper won't damage surfaces if removed carefully. Avoid low-quality adhesives that may leave residue or peel veneers.

Q: What types of paper are best for wood furniture protection?

A: Vinyl-coated contact papers or laminated varieties provide optimal scratch resistance. For temporary use, choose repositionable papers with gentle adhesive.

Q: How long does contact paper last on wood furniture?

A: High-quality contact paper lasts 2-5 years with proper application. Avoid prolonged moisture exposure and direct sunlight to maximize longevity.

Latest news

-

High-Quality Furniture Decoration Paper for Stylish Interiors

NewsJul.24,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025