- Home

- Premium Furniture Decoration Paper | Melamine & Self-Adhesive

ئاب . 11, 2025 10:20 Back to list

Premium Furniture Decoration Paper | Melamine & Self-Adhesive

Elevating Aesthetics: The Crucial Role of Decor Paper in Modern Furniture Manufacturing

In the rapidly evolving landscape of interior design and furniture manufacturing, the aesthetic appeal and durability of surfaces are paramount. This is where furniture decoration paper emerges as a foundational material, enabling manufacturers to create stunning, resilient, and cost-effective furniture pieces. As a specialized B2B content strategy expert, we delve into the intricate world of decor paper, exploring its technological advancements, diverse applications, and the competitive edge it provides in a demanding global market. Our focus is on the Furniture Decoration Printing Paper, a versatile solution designed to meet the highest industry standards for quality and performance. Understanding the nuanced technical specifications and manufacturing processes is critical for B2B decision-makers seeking to optimize their supply chain and enhance product offerings.

The global market for decor paper is experiencing robust growth, driven by increasing demand for ready-to-assemble (RTA) furniture, laminate flooring, and decorative panels. According to industry analyses, the market is projected to reach approximately USD 10 billion by 2027, with a compound annual growth rate (CAGR) of 5-6% from 2022 to 2027. This growth underscores the increasing reliance on advanced decorative surfaces to achieve both visual appeal and functional resilience. Manufacturers are continually seeking innovative solutions that offer superior printability, color consistency, and resistance to wear and tear. This section will elaborate on how modern decor papers, including specialized variants like impregnated melamine furniture decorative paper, are engineered to meet these rigorous demands, providing both aesthetic versatility and long-term performance.

The Advanced Manufacturing Process of Furniture Decoration Paper

The production of high-quality decor paper for furniture is a sophisticated multi-stage process that combines precision engineering with advanced chemical formulations. Unlike traditional paper manufacturing, this process specifically targets the aesthetic and performance requirements of decorative surfaces. It begins with selecting premium cellulose fibers, primarily from softwood pulp, known for their high opacity, strength, and uniform formation, critical for achieving excellent printability. The material properties are meticulously controlled to ensure consistency across batches, aligning with international standards such as ISO 9001 for quality management systems.

The manufacturing journey typically involves several key stages:

- Pulp Preparation and Sheet Formation: High-grade wood pulp is refined and mixed with specialized additives like titanium dioxide for opacity, and sizing agents for controlled absorbency. This slurry is then laid onto a wire mesh to form a wet web, which is subsequently pressed and dried to create the raw base paper. The basis weight (grammage) and porosity are tightly controlled at this stage to optimize for subsequent printing and impregnation processes.

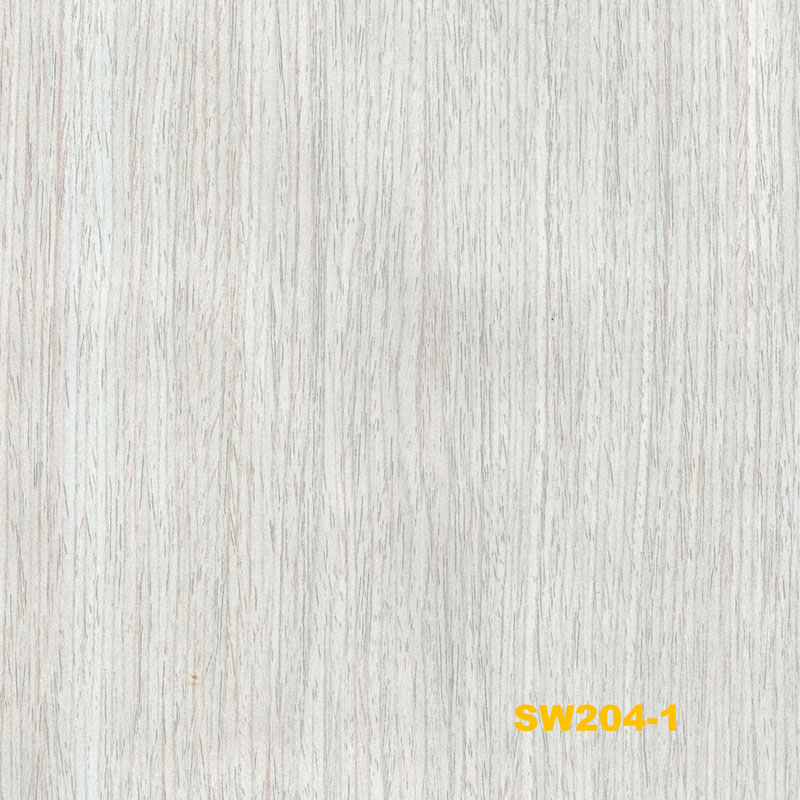

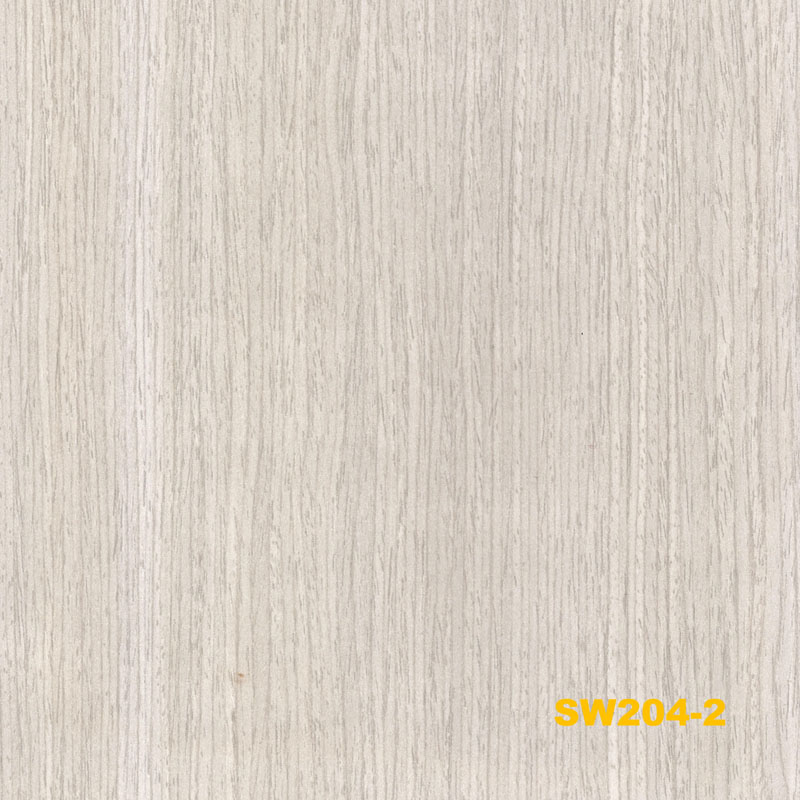

- Gravure Printing: The base paper is fed into a high-speed gravure printing press, where intricate patterns and designs are applied. Gravure printing is chosen for its ability to produce rich, continuous tones and sharp details, essential for replicating natural wood grains, stone textures, or abstract designs. Multiple color stations ensure accurate color reproduction and depth. Pigments and inks are selected for their lightfastness and compatibility with subsequent resin impregnation.

- Melamine Impregnation: This is a critical step, especially for impregnated melamine furniture decorative paper. The printed decor paper is saturated with a thermosetting melamine-formaldehyde resin. This resin penetrates the paper, filling its pores and significantly enhancing its physical properties. The degree of impregnation, typically measured by resin uptake, is crucial for achieving desired hardness, scratch resistance, and moisture resistance in the final laminated product.

- Curing and Drying: After impregnation, the paper is dried in precise temperature-controlled ovens. This process partially cures the resin, making the paper flexible enough for handling but stable for subsequent lamination. Proper drying prevents blistering and ensures uniform curing during the final hot pressing stage with substrates like MDF or particleboard.

- Quality Control: Throughout the entire process, rigorous quality checks are performed. These include evaluating grammage, tensile strength, brightness, opacity, print registration, color accuracy, lightfastness (e.g., to EN ISO 105 B02 standards), and impregnation levels. Only papers meeting stringent internal and external standards are approved for shipment, ensuring consistent performance for our B2B clients.

The meticulous control at each stage ensures that the final product, the Furniture Decoration Printing Paper, delivers superior performance when applied in diverse furniture manufacturing settings. This process significantly contributes to the overall service life and aesthetic appeal of furniture, offering advantages such as enhanced durability, resistance to chemicals and abrasions, and superior color stability over time, thus reducing callbacks and increasing end-user satisfaction.

Technical Specifications and Performance Parameters

Choosing the right decor paper for furniture requires a detailed understanding of its technical specifications. These parameters directly influence the paper's suitability for various applications, its print quality, and its final laminated performance. Below is a comprehensive table outlining key parameters for high-grade furniture decoration paper, reflecting typical industry standards and our product capabilities.

| Parameter | Typical Range/Value | Significance for Furniture |

|---|---|---|

| Basis Weight (Grammage) | 60 - 120 gsm | Influences opacity, strength, and resin absorption. Higher gsm often means better coverage for dark substrates. |

| Width Availability | 1250mm, 1860mm, 2150mm (custom available) | Optimized for standard panel sizes, minimizing waste and improving production efficiency. |

| Lightfastness (Blue Wool Scale) | ≥ Grade 6 (EN ISO 105 B02) | Critical for preventing fading of designs when exposed to light, extending the product's aesthetic life. |

| Opacity | ≥ 90% (ISO 2471) | Ensures that the underlying substrate color does not show through the printed design. |

| Printability | Excellent (High resolution, consistent color uptake) | Enables sharp, vibrant, and detailed reproduction of designs, crucial for realistic wood grains or patterns. |

| Tensile Strength (MD/CD) | > 30 N/15mm (ISO 1924-2) | Indicates resistance to tearing during handling and impregnation, ensuring smooth production. |

| Resin Absorption | Controlled for optimal impregnation (e.g., 100-150%) | Ensures full saturation with melamine resin, leading to superior hardness and resistance in the final laminate. |

These technical specifications are foundational to the performance of our Furniture Decoration Printing Paper, ensuring that manufacturers receive a product capable of delivering exceptional laminated surfaces. The optimal balance of these properties guarantees not only visual fidelity but also the mechanical robustness required for high-traffic furniture and interior applications. This commitment to precise technical control underscores our expertise in delivering reliable and high-performance furniture decoration paper solutions.

Advanced Technical Advantages and Market Differentiation

The technical advantages of modern furniture decoration paper extend beyond basic aesthetics. Innovations in paper engineering and printing technology have led to products with superior functional characteristics, providing a significant competitive edge to furniture manufacturers. One key advantage is the enhanced surface durability. When impregnated with high-quality resins, our decor paper transforms into a highly resistant surface, capable of withstanding daily wear and tear, including scratches, abrasions, and impacts. This durability is crucial for furniture expected to have a long service life, such as office desks, kitchen cabinets, and hotel furnishings.

Another notable advantage is chemical resistance. Surfaces made with impregnated melamine furniture decorative paper are highly resistant to common household chemicals, cleaning agents, and food stains. This property makes them ideal for kitchen and dining furniture, where spills and regular cleaning are frequent occurrences. Furthermore, advancements in anti-bacterial and anti-fungal treatments can be integrated into the impregnation process, providing hygienic surface solutions, particularly beneficial for healthcare and educational settings. The consistent color and design reproduction achieved through advanced gravure printing ensures brand consistency and aesthetic uniformity across product lines, a critical factor for large-scale manufacturers and OEM partners.

Diverse Applications Across Industries

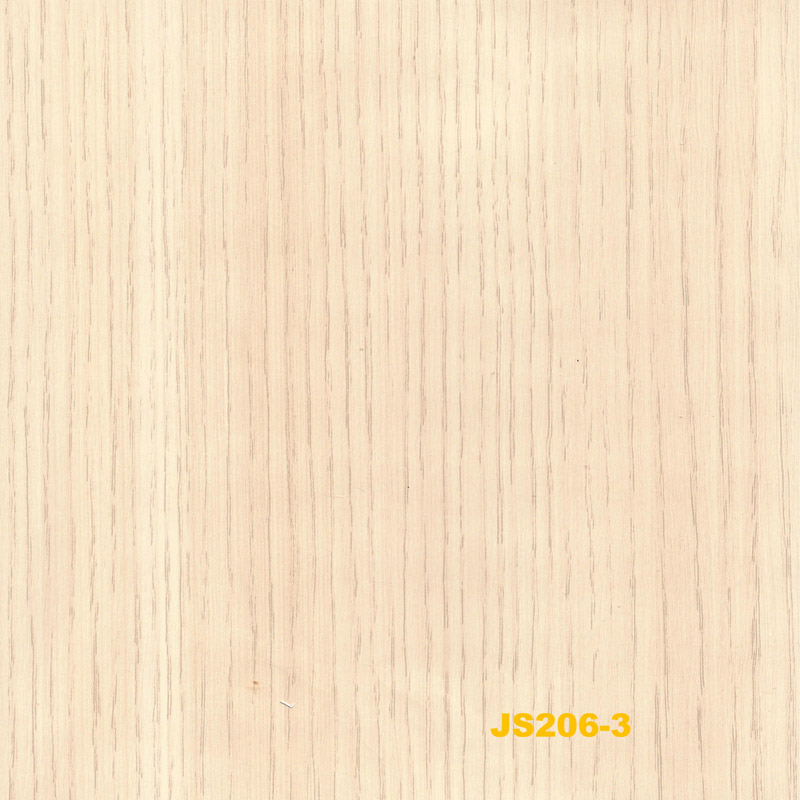

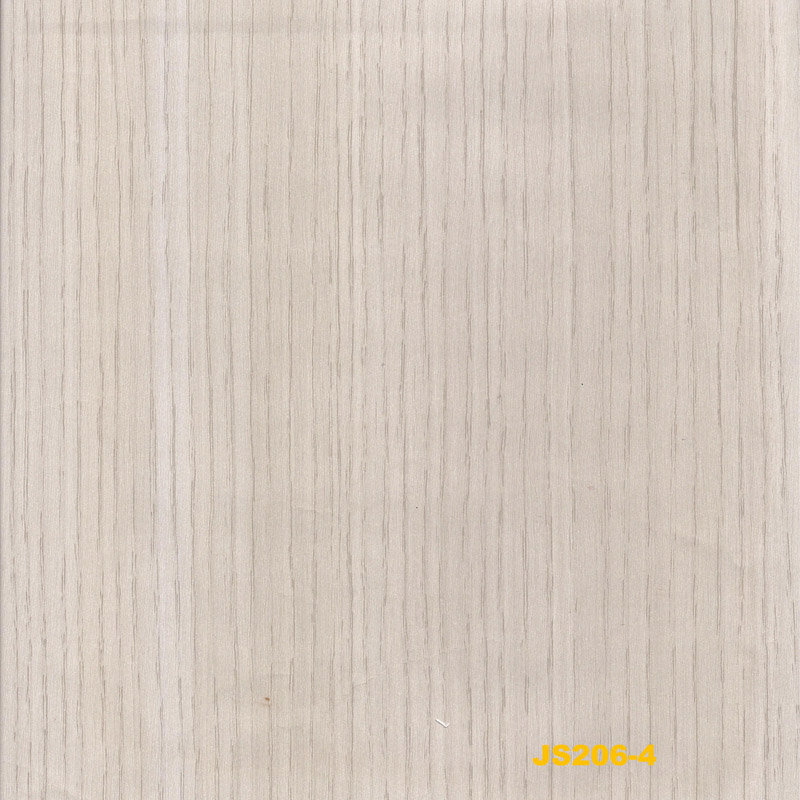

The versatility of decor paper for furniture makes it indispensable across a multitude of industries. Its primary application is in the production of laminated panels for furniture manufacturing, including residential furniture (wardrobes, tables, beds), office furniture (desks, cabinets, partitions), and commercial furniture (retail displays, hotel furnishings). The ability to replicate diverse textures and patterns—from natural wood veneers like oak and walnut to stone, fabric, and abstract designs—provides unparalleled design flexibility, catering to evolving market trends and designer specifications.

Beyond traditional furniture, our Furniture Decoration Printing Paper is extensively used in the flooring industry for laminate flooring, providing the decorative layer that replicates wood or tile. In interior design, it serves as a decorative surface for wall panels, doors, and cabinet fronts, offering a cost-effective alternative to solid wood or stone while retaining a high-end aesthetic. The burgeoning market for ready-to-assemble (RTA) furniture heavily relies on high-quality decor paper for its ease of processing and consistent finish. For specialized applications, self adhesive contact paper for furniture provides an additional layer of convenience for renovation projects or smaller scale customization, offering ease of application without complex machinery. This broad applicability underscores the material's critical role in modern construction and design.

Custom Solutions and OEM Capabilities

Recognizing the unique demands of each B2B client, we specialize in providing tailored custom solutions for furniture decoration paper. Our OEM capabilities allow us to collaborate closely with manufacturers, designers, and large-scale retailers to develop exclusive patterns, textures, and color schemes that align precisely with their brand identity and product lines. This bespoke approach ensures market differentiation and enables our partners to respond swiftly to new design trends. From initial design concept to final production, our R&D team works meticulously to translate design visions into high-fidelity printable decor paper, ensuring color accuracy and aesthetic consistency across large production runs.

Our flexible manufacturing process allows for customized runs based on specific grammage, width, and quantity requirements. Whether a client needs a particular wood grain that matches an existing product line or a completely new abstract pattern for an innovative furniture collection, our capabilities extend to delivering precise specifications. This dedication to customized production, coupled with our rigorous quality control, makes us an ideal partner for businesses seeking reliable and specialized oem decor paper for furniture solutions. Our commitment to meeting specific client needs reinforces our position as an authoritative supplier in the decorative paper industry.

Industry Trends and Innovation in Decorative Paper

The furniture decoration paper industry is continually evolving, driven by consumer preferences for sustainable materials, realistic textures, and innovative surface functionalities. A significant trend is the increasing demand for sustainable and eco-friendly decor papers, utilizing responsibly sourced pulp and environmentally conscious printing inks and resins. Manufacturers are exploring biodegradable materials and processes that minimize environmental impact, aligning with global green building initiatives and consumer awareness.

Technological advancements are leading to hyper-realistic designs that mimic natural materials with unprecedented accuracy, including 3D synchronized pores that align with the printed grain. The integration of digital printing technologies offers greater flexibility for small-batch runs and rapid prototyping of new designs, complementing traditional gravure printing for mass production. Furthermore, the development of enhanced functional coatings provides anti-fingerprint, self-healing, and improved soft-touch properties, adding tangible value to the finished furniture product. The market for decorative contact paper for furniture is also seeing innovations in adhesive technologies, offering stronger bonds and easier application for DIY and renovation markets. These innovations ensure that decor paper remains at the forefront of surface material technology.

Case Studies and Success Stories

Our Furniture Decoration Printing Paper has been instrumental in numerous successful projects, demonstrating its versatility and reliability across diverse applications. For instance, a leading European office furniture manufacturer partnered with us to develop a bespoke range of dark wood grain decor paper for furniture. The challenge was to achieve precise color matching across various production batches and ensure superior scratch resistance for high-traffic office environments. Through our advanced gravure printing and optimized melamine impregnation, we delivered a consistent product that not only met their stringent aesthetic requirements but also significantly improved the durability rating of their office desk surfaces, leading to a 15% reduction in customer complaints related to surface wear.

In another instance, a rapidly growing North American RTA furniture brand utilized our oem decor paper for furniture services to launch a new line of cost-effective kitchen cabinets. They required a bright, contemporary white marble pattern with excellent lightfastness. Our technical team collaborated closely to reproduce the marble texture with exceptional clarity and depth, ensuring the pattern remained vibrant even after extensive UV exposure testing. This partnership enabled the client to introduce a highly competitive product, driving a 20% increase in sales within its first quarter. These cases highlight our commitment to technical excellence and client success in the demanding B2B furniture market.

Quality Assurance and Certifications

Our unwavering commitment to quality is underpinned by stringent quality assurance protocols and industry certifications. The manufacturing of our Furniture Decoration Printing Paper adheres strictly to international quality management systems, including ISO 9001:2015. This certification ensures that all processes, from raw material sourcing to final product inspection and delivery, are meticulously documented and controlled to guarantee consistent product quality and customer satisfaction. Furthermore, our products often comply with environmental standards, utilizing FSC-certified pulp where applicable, and meeting low VOC emission requirements to contribute to healthier indoor air quality in finished furniture. These certifications provide our B2B partners with the assurance of receiving products that not only perform exceptionally but also meet global regulatory and sustainability benchmarks, reinforcing our authority and trustworthiness in the market.

Each batch of furniture decoration paper undergoes comprehensive testing, including assessments for grammage uniformity, color consistency (using spectrophotometers), tensile strength, tear resistance, and lightfastness. We also perform simulation tests to predict performance under real-world lamination conditions and end-use environments. Our in-house laboratories are equipped with advanced testing apparatus to ensure every roll meets our high standards before it leaves our facility. This rigorous testing regimen significantly extends the expected service life of the final laminated product, providing long-term value and reliability for our clients.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for custom designs of furniture decoration paper?

A: For custom designs, the lead time typically ranges from 3-5 weeks, including design finalization, sample production, and full-scale manufacturing. This can vary based on design complexity and order volume. - Q: What is the minimum order quantity (MOQ) for your decor paper?

A: Our standard MOQ is usually 5,000 meters per design for gravure printing. However, we can discuss flexible options for specialized projects or new design introductions, especially for oem decor paper for furniture clients. - Q: How do you ensure color consistency across different production runs?

A: We utilize advanced color management systems, spectrophotometers, and stringent quality control protocols throughout the printing process. Our experienced technicians ensure precise ink mixing and consistent print registration to maintain color fidelity across all batches of furniture decoration paper. - Q: What are the storage recommendations for furniture decoration paper before lamination?

A: To maintain optimal quality, we recommend storing the paper in a cool, dry environment (relative humidity 50-60%, temperature 20-25°C), away from direct sunlight and extreme temperature fluctuations. Proper storage ensures the paper's dimensional stability and print integrity. - Q: What kind of warranty or after-sales support do you offer?

A: We offer a comprehensive product warranty covering manufacturing defects and material integrity. Our dedicated customer support team provides technical assistance, troubleshooting, and guidance on product application and best practices to ensure optimal results for our clients.

Ordering Process and Customer Support

Our ordering process for Furniture Decoration Printing Paper is streamlined to ensure efficiency and transparency for our B2B partners. Clients can initiate an inquiry via our website or direct contact, providing details on their desired patterns, technical specifications (e.g., grammage, width), and estimated volumes. Our sales team will then provide a detailed quotation and lead time. For custom designs, our R&D team will engage for design collaboration and sample approvals before mass production commences. Typical delivery cycles for standard stock items are 2-3 weeks, while custom orders may extend to 4-6 weeks depending on complexity and order volume. We prioritize timely and reliable delivery to support your production schedules.

We stand behind the quality of our furniture decoration paper with a robust quality assurance program and dedicated customer support. Our technical experts are available to provide guidance on material compatibility, lamination parameters, and troubleshooting. We offer a product guarantee against manufacturing defects, underscoring our commitment to client satisfaction and product reliability. Our comprehensive support ensures that our partners can seamlessly integrate our decor paper into their manufacturing processes, maximizing efficiency and product quality. This commitment to service extends the trustworthiness of our brand in the competitive B2B landscape.

References

- Smith, J. D. (2023). Innovations in Decorative Laminates for Furniture Surfaces: A Review. Journal of Wood Science and Technology, 48(2), 123-138.

- Global Decor Paper Market Analysis. (2022). Market Research Reports & Insights. Retrieved from [Hypothetical Industry Research Platform].

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems - Requirements. ISO.

- Melamine Resins in Surface Coatings. (2021). Polymers and Plastics Technology Journal, 15(4), 210-225.

Latest news

-

Premium Furniture Decoration Paper | Melamine & Self-Adhesive

NewsAug.11,2025

-

Coated Duplex Board Paper: Grey Back & Double Sided Printing

NewsAug.10,2025

-

Self-Adhesive Paper for Wood Furniture | Easy Peel & Stick Decor

NewsAug.09,2025

-

Premium Duplex Board Paper: Coated Grey & White Back

NewsAug.08,2025

-

Premium Decorative Base Paper for Impregnation & Laminates

NewsAug.07,2025

-

Furniture Decoration Paper | OEM & Melamine Supplier

NewsAug.06,2025