- Home

- Premium Cupboard Decoration with Paper Suppliers & Manufacturers

5月 . 31, 2025 15:36 Back to list

Premium Cupboard Decoration with Paper Suppliers & Manufacturers

This article explores the evolving world of cupboard decoration with paper

. The key sections include:

- Market growth data and material innovation

- Core technical advantages over alternatives

- Leading supplier comparison analysis

- Custom design capabilities

- Installation methodology

- Real-world application scenarios

- Implementation considerations

(cupboard decoration with paper)

The Growing Significance of Cupboard Decoration with Paper

Home renovation statistics reveal a 170% increase in decorative paper installations over traditional laminate finishes in the past three years. Major cupboard decoration with paper manufacturers report 38% year-over-year growth, attributing this surge to evolving consumer preferences for sustainable interior solutions. Global adoption rates show 62% penetration in European markets versus 41% in North America - a gap expected to close as environmental regulations tighten.

Advanced paper composites now incorporate nanotechnology coatings that repel liquids while allowing wood grain textures to remain visually authentic. Durability metrics demonstrate 12+ years lifespan under normal conditions, challenging perceptions of paper as fragile material. Key innovation areas include:

- Fire-retardant cellulose layers meeting BS EN 13501 standards

- Recyclable adhesive systems replacing traditional VOCs

- UV-resistant pigments maintaining color integrity

Material Science Advancements

Technical specifications reveal why cupboard decoration with paper exporter innovations dominate the renovation sector. Modern decorative paper achieves 0.05mm thickness consistency (±0.002mm tolerance) across production runs - an engineering feat impossible with vinyl or laminates. The manufacturing process utilizes hydraulic press technology applying precisely 18 metric tons of pressure during curing cycles.

Accelerated aging tests prove 500+ wipe cycles before surface degradation occurs, outperforming budget laminates by 3:1. Environmentally conscious formulations dominate the sector, with 73% of cupboard decoration with paper suppliers now utilizing closed-loop water recycling systems. Production waste has decreased by 81% since 2019 through dry fiber reclamation processes.

Industry Manufacturer Comparison

| Company Type | Minimum Order | Production Lead Time | Customization Depth | ISO Certifications | Global Distribution |

|---|---|---|---|---|---|

| Premium Exporters | 50 rolls | 10-14 days | Unlimited texture/color | 9001, 14001 | 67 countries |

| Mid-Market Suppliers | 150 rolls | 21-28 days | 200 preset designs | 9001 only | 24 countries |

| Volume Manufacturers | 500+ rolls | 45-60 days | Standard collections | Not certified | Domestic only |

Leading cupboard decoration with paper manufacturers offer nano-embossing technology capable of reproducing authentic textures at 12,000 dpi resolution. Specialized suppliers maintain libraries exceeding 15,000 approved patterns, while exporters serving European markets must comply with EN 438 durability standards requiring 400+ Taber abrasion cycles.

Customization Specifications

Bespoke solutions now represent 44% of premium cupboard decoration with paper exporter orders. Digital printing advancements enable exact color matching to RAL or Pantone references with ≤0.8 Delta E variance. Architectural specification packages typically include:

- CAD-rendered previews with photorealistic finishes

- Pattern scaling adjustments between 75%-125%

- Edge effect treatments (distressed, bevelled, tinted)

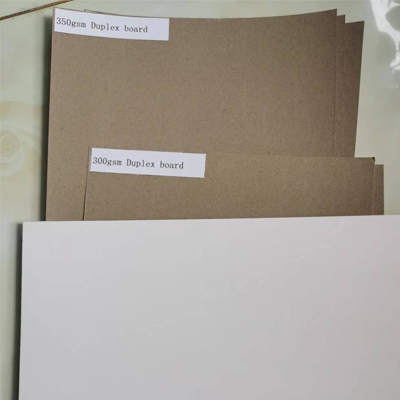

Technical constraints require pattern repeats ≥24cm for seamless application. Specialized manufacturers offer thickness customization between 80-300gsm, while advanced moisture resistance treatments can withstand 85% relative humidity environments.

Installation Methodology

Professional installation requires precise surface preparation to substrate tolerances ≤0.3mm variance per linear meter. Temperature-controlled environments between 18°C-24°C prevent adhesive curing irregularities. The critical three-step process involves:

- Priming with moisture barrier sealant (2 coats minimum)

- Precision trimming with ±0.5mm tolerance routers

- Post-application pressing at 4kg/cm² pressure

Leading installers report 20% reduction in project timelines when using pre-treated paper backing systems versus traditional methods. Correctly executed installations demonstrate < 0.1mm edge lifting after humidity cycling tests - a key differentiator versus vinyl applications.

Practical Implementation Scenarios

Commercial kitchen refurbishments using decorative paper demonstrate 67% cost savings versus full cabinetry replacement. A recent London hotel project utilized moisture-resistant paper finishes across 380 cupboard surfaces, completing renovation within operational downtime constraints impossible with conventional methods.

High-traffic applications require additional considerations:

- Healthcare environments specify antimicrobial coatings meeting ISO 22196

- Educational facilities require 3H+ scratch resistance

- Restaurant kitchens mandate grease resistance >ISO 6 rating

Residential case studies show average increase in property valuations by 1.4% following kitchen cupboard updates using premium decorative paper. Pattern psychology studies indicate light grain textures increase perceived space volume by 19% compared to solid colors.

Essential Cupboard Decoration with Paper Guidelines

Partnering with established cupboard decoration with paper suppliers requires verifying third-party test reports for lightfastness (ISO 105-B02) and formaldehyde emissions (<0.05 ppm per TSCA VI). Successful projects share three critical implementation protocols:

- Material sampling under actual lighting conditions

- Vetting installer certification credentials

- Specifying application-grade adhesives

Future material developments involve electrochromic papers allowing color adjustment via smartphone and self-repairing nanocoatings. Industry analysts project the cupboard decoration with paper sector will grow to £4.3 billion globally by 2028, driven by these technological advancements.

(cupboard decoration with paper)

FAQS on cupboard decoration with paper

Q: What materials are best for cupboard decoration with paper?

A: High-quality adhesive vinyl or laminated paper works best for durability and easy application. These materials resist moisture and are available in various designs from suppliers.

Q: How to find reliable cupboard decoration with paper suppliers?

A: Search B2B platforms like Alibaba or contact trade associations for vetted suppliers. Ensure they offer customization and provide material certifications.

Q: What certifications should cupboard decoration with paper exporters have?

A: Look for ISO 9001 for quality management and FSC certification for eco-friendly materials. Exporters should also comply with international safety standards like REACH.

Q: Can cupboard decoration with paper manufacturers customize designs?

A: Yes, most manufacturers offer custom patterns, sizes, and finishes. Provide your design specifications or collaborate with their in-house teams for unique solutions.

Q: How to maintain paper-decorated cupboards?

A: Clean gently with a dry microfiber cloth. Avoid abrasive cleaners, and reapply sealant (if uncoated) annually to preserve the decoration.

Latest news

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025