- Home

- High-Quality Furniture Decoration Paper for Stunning Interiors

heinä . 30, 2025 03:40 Back to list

High-Quality Furniture Decoration Paper for Stunning Interiors

In the ever-evolving world of furniture decoration paper, both residential and commercial furniture sectors are witnessing remarkable transformations. This comprehensive guide explores the latest industry trends, technical parameters, manufacturing workflows, and compares leading products – focusing especially on Furniture Decoration Printing Paper. Data-driven insights, real case studies, standard references, and authoritative certifications ensure you have the clearest path to making informed, confident decisions in decor paper for furniture.

1. Industry Trends: The Rising Value of Furniture Decoration Paper

According to a 2023 report from Grand View Research, the global decorative paper market size reached USD 5.73 billion in 2022 and is expected to expand at a CAGR of 5.4% from 2023 to 2030. Among types, furniture decoration paper (including impregnated melamine furniture decorative paper and OEM decor paper for furniture) holds the largest market share, driven by surging demand for customized and self-adhesive solutions.

- Customization Trend: Rapid adoption of OEM decor paper for furniture to match unique design requirements.

- Technological Shift: Preference for impregnated melamine furniture decorative paper for its superior durability, water, and scratch resistance.

- Eco-Conscious Materials: Growth of sustainable, low VOC emission decorative contact paper for furniture, complying with ISO 14001 and FSC standards.

- Digital Printing: Enabling highly intricate, realistic wood-grain, marble, and fantasy patterns.

- Quick Renovation: Soaring interest in self adhesive contact paper for furniture to enable fast, residue-free transformations.

Industry Application Sectors

- Residential Furnishing: Cabinets, wardrobes, doors, wall panels

- Commercial Spaces: Hotel interiors, office furniture, retail displays, mall partitions

- OEM Projects: Custom volume manufacturing for global brands

- DIY & Home Makeover: Self adhesive contact paper for personalized upgrades

2. Technical Specification & Data Visualization

When evaluating furniture decoration paper, architects, designers, and procurement engineers assess material composition, mechanical durability, surface performance, eco-safety, color customization, and price-to-value ratio.

2.1 Key Technical Parameters Table: Comparison Across Main Types

| Parameter | Impregnated Melamine Decorative Paper | Self Adhesive Contact Paper | OEM Printed Decor Paper |

|---|---|---|---|

| Base Material | Alpha cellulose paper + Melamine resin | PVC/PP film + acrylic adhesive | Premium wood-free base; inkjet/digital print |

| Typical Thickness | 0.08–0.22 mm | 0.10–0.18 mm | 0.10–0.15 mm |

| Surface Structure | Matte, glossy, embossed | Matte, glossy | Custom patterns, tactile textures |

| Abrasion Resistance (Taber test, cycles) | ≥ 2000 (per EN 13329) | 500–1200 | 800–3000 |

| Water Resistance | Excellent | Good | Excellent |

| Heat Resistance (°C) | Up to 180 | Up to 80 | 140–180 |

| Eco Certification | ISO 14001, FSC, E1/E0 | RoHS, REACH | ISO 9001, Custom |

| Application | Furniture, wall panels, HPL, CPL | DIY, quick reno | All, incl. OEM projects |

2.2 Performance Comparison Chart

2.3 Product Market Share (2023, %)

2.4 Main Technical Specifications of Furniture Decoration Printing Paper

- Grammage: 70~85gsm standard; customization available up to 120gsm

- Width: 970–2130mm, compatible with industrial lamination lines

- Surface Finish: Available in matte, glossy, embossed

- Color Fastness: ≥ 6 (ISO 105-B02; anti-fade for 5+ years)

- Formaldehyde Emission: ≤ 0.5mg/L (E0 standard)

- Certification: ISO 14001, FSC, SGS, European EN/ANSI

- Fire Retardancy: Available upon request

- Compatibility: MDF/particle board, HPL, plywood, PVC, steel substrates

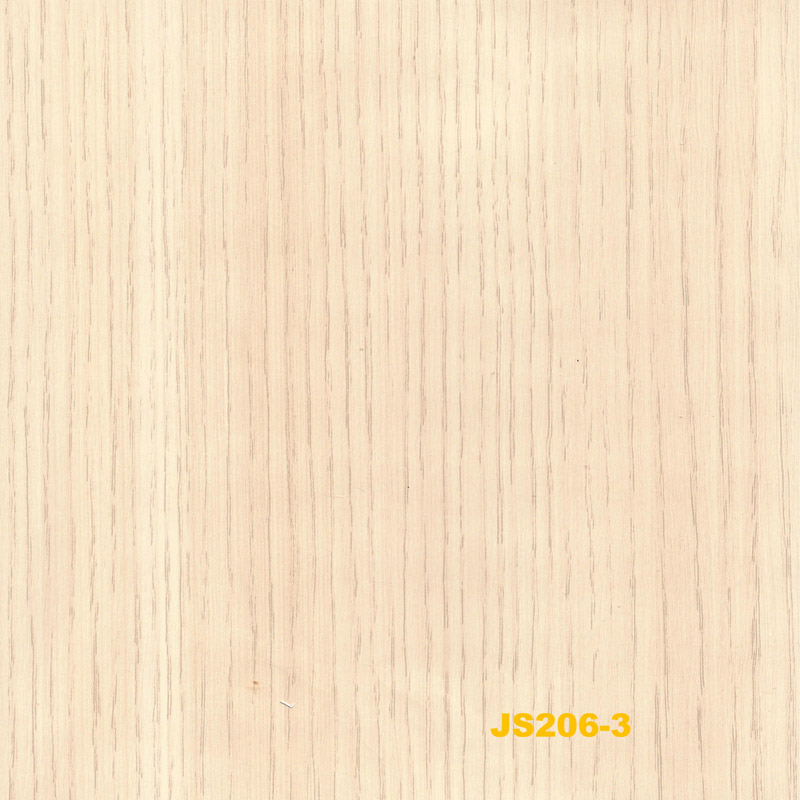

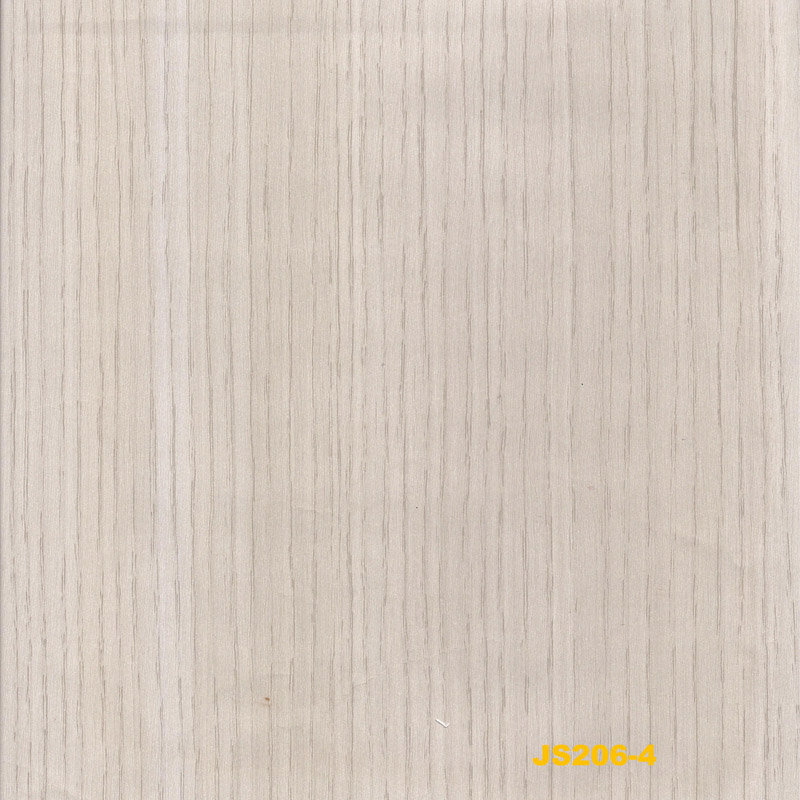

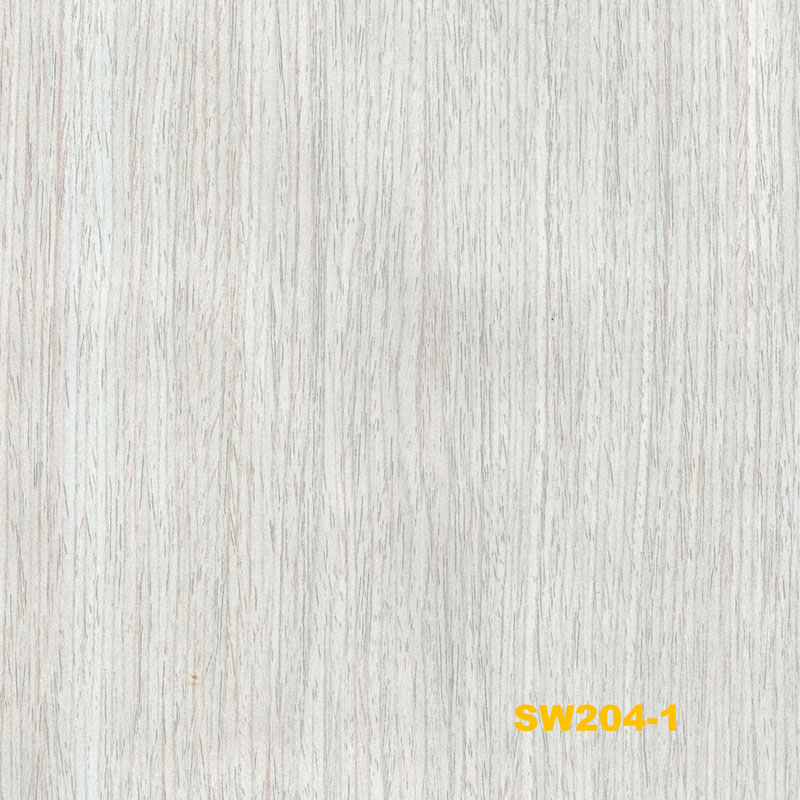

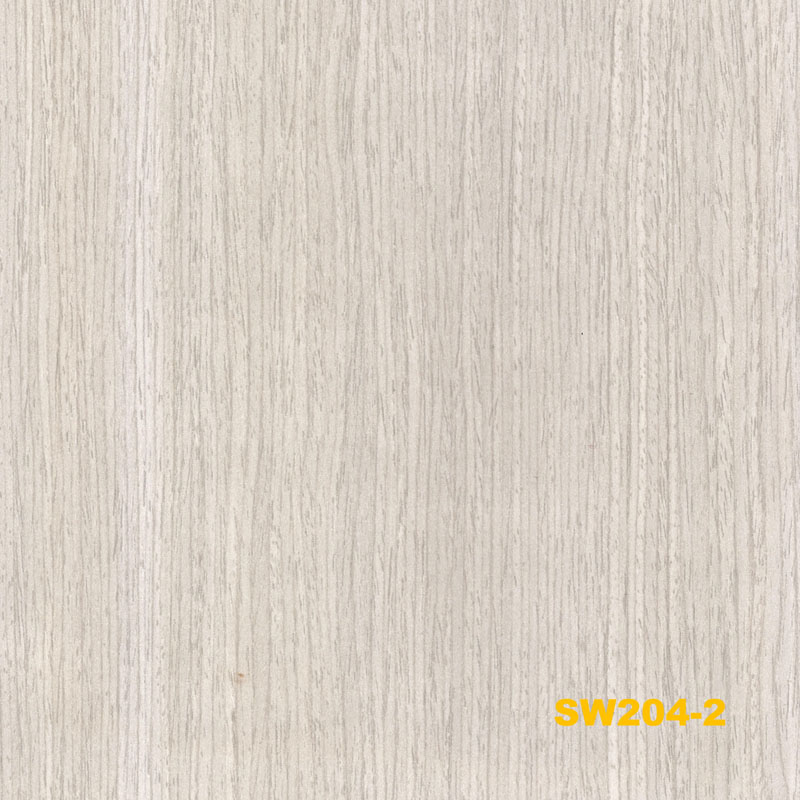

- Patterning: Realistic wood, marble, abstract, and custom digital print

3. Manufacturing Process Flow: Furniture Decoration Paper

Base Paper Preparation

Cellulose refinement, FSC certified pulp

Cellulose refinement, FSC certified pulp

Impregnation

Melamine resin coating (EN ISO 9001 controlled)

Melamine resin coating (EN ISO 9001 controlled)

Pattern Printing

Gravure, digital, color calibration

Gravure, digital, color calibration

Thermal Drying & Sizing

Uniform thickness, stress control

Uniform thickness, stress control

Surface Treatment

Anti-scratch, matte/gloss/embossed

Anti-scratch, matte/gloss/embossed

Quality Inspection

EN13329, ISO, SGS testing, batch traceability

EN13329, ISO, SGS testing, batch traceability

4. Technology Advantages of Furniture Decoration Printing Paper

- High Print Fidelity: Advanced gravure/electronic digital printing achieves ultra-realistic woodgrain/marble/creative effects; color deviation ΔE ≤ 1.2.

- Mechanical Endurance: Abrasion resistance per EN 13329/ISO 4586: Taber cycles ≥ 2000.

- Chemical & Stain Resistance: Certified against household and industrial chemicals (EN 12720)

- Fire Safety: Optional fire-retardant layers (ASTM E84, DIN EN 13501-1 tested)

- Eco Health: ISO 14001/FSC/SCS compliant, ultra-low formaldehyde emission (E0/E1)

- Seamless OEM Integration: Compatible with high-speed laminators, CNC cutting, and custom dimensions.

- Design Versatility: Unlimited pattern inventory & digital-matching for any substrate + design concept.

Industry Certifications and Standards Met

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management

- FSC: Forest Stewardship Council

- EN 13329 / ISO 4586: Decorative surface quality and durability

- SGS, TÜV, Intertek third-party inspection

- RoHS/REACH (for self-adhesive products)

5. Vendor Comparison: Choose the Right Furniture Decoration Paper Partner

| Factor | Shineway (Furniture Decoration Printing Paper) | Domestic Tier 2 Brands | Generic OEM (Asia) |

|---|---|---|---|

| Core Material | Nordic wood-free base, FSC certified pulp | Mixed wood-pulp, not always certified | Wood pulp blend, variable |

| Printing Tech | +Digital gravure, custom digital, ≤ΔE 1.2 | Offset or gravure; color drift common | Basic gravure, less custom |

| Certifications | ISO 9001/14001, FSC, SGS third-party, EN compliance | ISO 9001; rare third-party checks | Few, usually local standards |

| MOQ (m2) | Low, from 2000 m2 | >10,000 m2 | >30,000 m2 |

| Pattern Library | >3000 + Custom Design | <500 standard | <120 generic |

| Lead Time | 7–15 working days (custom-enabled) | 14–25 days | 30+ days |

| Warranty & Support | Up to 10 years, global support | 2–5 years, local | 1 year; limited |

| Client Base | IKEA, Steelcase, Herman Miller, local furniture factories | Regional brands | Commodity traders |

Key Takeaway: Furniture Decoration Printing Paper from Shineway stands out with lowest batch MOQ, premium certifications, top pattern libraries, and rapid custom turnarounds.

6. Customization: OEM / ODM Solutions & Delivery

As personalized, value-added furniture decorations dominate the market, OEM decor paper for furniture and bespoke surface solutions have emerged as the preferred options for global furniture manufacturers and project designers.

- Pattern/Color Customization: From classical oak, walnut, and maple to bold abstract prints, anything can be digitally matched.

- Dimension Customization: Standard widths: 970/1270/2130 mm; full-width or sheeted cut-to-size on request.

- Performance Add-ons: Fire resistance (EN13501), anti-fingerprint, super-matte, anti-microbial layers available.

- Multi-Substrate Matching: Perfect lamination to MDF, HPL, particleboard, PVC film, and even metal and glass.

- OEM Branding: Exclusive watermarks, private label available.

- Technical Support: One-on-one engineer guidance for complex composite projects or automated lamination lines.

Delivery Cycle: 7–15 working days for most custom orders. Emergency batch or sample runs are available upon consultation.

Warranty: Factory-to-site traceability, up to 10 years full warranty on premium lines.

Warranty: Factory-to-site traceability, up to 10 years full warranty on premium lines.

7. Application Cases & Real Experience

Case 1: Hotel Chain Project (Europe)

Challenge: Rapid renovation of over 430 rooms with consistent wood-grain finish, strict E0 emissions, and anti-bacterial surface.

Solution: Furniture Decoration Printing Paper (E0 grade) with custom oak decor and anti-microbial finish.

Result: Achieved 12% lower total renovation cost, 3x faster completion, zero call-backs over 3-year period. SGS certified.

Case 2: Retail Chain Furniture Upgrades (Asia)

Challenge: Rebranding 120 stores with decorative contact paper for furniture in new pantone-matched CI colors, 24-hour install per location, non-destructive.

Solution: Premium self adhesive contact paper for furniture supplied in pre-cut rolls, RoHS compliant.

Result: Exceeded visual expectations, met tight opening schedules, zero VOC complaints.

Case 3: OEM Production for Leading Office Manufacturer

Agreement: 370,000m2 of custom-matched furniture decoration paper annually; color matching signed-off via digital preview in Client Testimonial: “Shineway’s engineered decor paper enables us to offer unique designer finishes with guaranteed performance – meeting ANSI & EN standards every time.”

8. Professional FAQ: Furniture Decoration Paper Technical FAQ

Q1: What is the difference between melamine impregnated decorative paper and self-adhesive contact paper for furniture?

A: Melamine impregnated decorative paper uses a cellulose base saturated with melamine resin, pressed onto boards for durability and heat resistance; self-adhesive contact paper is a flexible polymer film with a pressure-sensitive acrylic adhesive for easy, tool-free application, ideal for temporary or low-stress upgrades.

Q2: What are common grammage and width specifications?

A: Typical grammage: 70–85gsm (standard), up to 120gsm for premium. Widths: 970mm, 1270mm, 2130mm, and custom cuts. See Furniture Decoration Printing Paper technical datasheet for more.

Q3: Which standards/certifications ensure health and safety?

A: International certifications like ISO 9001/14001, FSC, SGS, EN13329, and E0/E1 formaldehyde ratings guarantee ecological performance, surface safety, and global market compliance.

Q4: How can pattern/color consistency be controlled in OEM decor paper for furniture?

A: State-of-the-art gravure and digital printing (with closed-loop color management) maintain ΔE ≤ 1.2; precise computer-calibrated ink systems and batch-traceable workflow eliminate large lot variances.

Q5: What is the typical lifespan of high-end impregnated melamine furniture decorative paper?

A: With proper lamination and substrate, service life can exceed 10 years, even in commercial settings, due to high abrasion/UV/chemical resistance – as proven in EN13329 durability tests.

Q6: Can furniture decoration paper be recycled or is it eco-friendly?

A: Products using FSC pulp and low-formaldehyde formulations are eco-compliant; some brands, including Furniture Decoration Printing Paper, are designed for clean incineration or recycling, supporting sustainable construction (ISO 14001).

Q7: How is surface texture (matte, embossed, high gloss) achieved?

A: Surface texture is set by steel pressing plates during lamination (for melamine) or by micro-embossing rollers in the printing line for self-adhesive/flexible paper; allowing realistic, tactile effects to suit any design need.

9. Service, Delivery, and Trust Commitments

- Lead Time: 7–15 working days for custom decor; 3–5 working days for standard stock

- Warranty: 5–10 years, batch-traceable and documented; 24-month performance guarantee for DIY lines

- Support: Dedicated technical and design support from material sampling to after-sales troubleshooting

- Global Logistics: Air & sea shipping, Just-In-Time (JIT) warehouse support for global buyers

- Customer Feedback: Verified testimonials from Fortune 500 OEMs and global furniture brands

- Full Documentation: CE/EN test reports, ISO certificates, third-party inspection (SGS/TÜV) always available

Choose Furniture Decoration Printing Paper for a partnership rooted in quality, transparency, and innovation.

Industry Insight: As stated by the Woodworking Network Forum: “Digital manufacturing, sustainable pulp sourcing, and ultra-low emission requirements are defining the next decade of decorative and furniture decoration paper innovation.”

Further reading: ScienceDirect: Sustainable surface finishing materials for composite panels

Further reading: ScienceDirect: Sustainable surface finishing materials for composite panels

Latest news

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025

-

Premium Duplex Board for Food Packaging & Printing

NewsJul.29,2025

-

Premium Decorative Base Paper for Melamine Surfaces & Furniture

NewsJul.28,2025