- Home

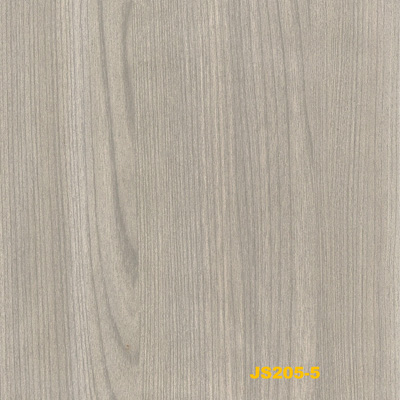

- Duplex Board with Gray back

መጋቢ . 04, 2025 11:10 Back to list

Duplex Board with Gray back

Duplex board manufacturing is a crucial segment in the packaging industry. Known for their strength, durability, and versatility, duplex boards are used in various sectors, from food packaging to pharmaceuticals. The process of manufacturing duplex boards involves converting raw materials into a robust product capable of withstanding external pressures while simultaneously being environmentally friendly.

A critical step often overlooked is the coating process. The duplex board’s surface is coated to enhance its printability, gloss, and resistance to moisture. Herein lies the manufacturer’s authority; selecting and applying the appropriate coatings requires in-depth knowledge and experience—underscoring the significance of expertise in delivering a product tailored to client specifications. Finally, the boards undergo cutting and trimming to meet specific dimensions and quality standards before being packaged for export. Trust in the product is fortified by rigorous quality checks, ensuring the boards conform to both international and local standards. With many exporters operating globally, only those with a proven track record of reliability and compliance continue to thrive. Duplex board manufacturing demand is anticipated to rise, driven by the push for more sustainable packaging solutions. Exporters with a commitment to quality, using innovative manufacturing processes anchored in expertise and transparency, are well-positioned to lead this industry. By prioritizing Experience, Expertise, Authoritativeness, and Trustworthiness, these manufacturers ensure their products not only meet but exceed the dynamic expectations of the global market. In conclusion, the duplex board manufacturing process is a symbiotic blend of art and science. The best exporters are those who strike a balance between maintaining traditional expertise and embracing technological advancements. They focus not just on producing quality duplex boards but also on sustainable practices, fostering trust, and providing authoritative solutions that address contemporary packaging needs. As global demand continues to shift towards eco-friendly products, manufacturers and exporters who adhere to these principles are likely to maintain a competitive edge in the international arena.

A critical step often overlooked is the coating process. The duplex board’s surface is coated to enhance its printability, gloss, and resistance to moisture. Herein lies the manufacturer’s authority; selecting and applying the appropriate coatings requires in-depth knowledge and experience—underscoring the significance of expertise in delivering a product tailored to client specifications. Finally, the boards undergo cutting and trimming to meet specific dimensions and quality standards before being packaged for export. Trust in the product is fortified by rigorous quality checks, ensuring the boards conform to both international and local standards. With many exporters operating globally, only those with a proven track record of reliability and compliance continue to thrive. Duplex board manufacturing demand is anticipated to rise, driven by the push for more sustainable packaging solutions. Exporters with a commitment to quality, using innovative manufacturing processes anchored in expertise and transparency, are well-positioned to lead this industry. By prioritizing Experience, Expertise, Authoritativeness, and Trustworthiness, these manufacturers ensure their products not only meet but exceed the dynamic expectations of the global market. In conclusion, the duplex board manufacturing process is a symbiotic blend of art and science. The best exporters are those who strike a balance between maintaining traditional expertise and embracing technological advancements. They focus not just on producing quality duplex boards but also on sustainable practices, fostering trust, and providing authoritative solutions that address contemporary packaging needs. As global demand continues to shift towards eco-friendly products, manufacturers and exporters who adhere to these principles are likely to maintain a competitive edge in the international arena.

Latest news

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025