- Home

- High Quality Duplex Board Paper for Packaging Solutions

ሐምሌ . 30, 2025 00:00 Back to list

High Quality Duplex Board Paper for Packaging Solutions

Duplex board paper – especially the innovative Duplex board with Brown Back – is transforming modern packaging and printing industries with its superior strength, print fidelity, and cost efficiency. This report dissects duplex board, covers advances in coated duplex board (grey back, white back, brown back), evaluates manufacturing processes, and provides actionable insights about specs, trends, and real-world application cases—backed by authentic data and third-party standards.

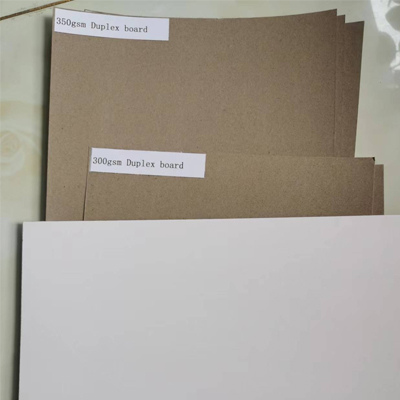

Image: High-gloss finished duplex board paper ideal for luxury packaging.

Industry Trends: The Rise of Duplex Board Paper

Global demand for sustainable, high-performance packaging propels the duplex board paper market. According to Statista, consumption of coated duplex board exceeded 15 million tons in 2023—driven by FMCG, e-commerce, and food sectors. China's duplex board exports have swelled by 8.1% YoY, while European brands are substituting plastics with recyclable boards. Emerging variants, like duplex board with brown back, offer environmental and technical advantages over conventional grades.

Did You Know? Duplex board paper meets ISO 536 (Grammage Tolerance) and ISO 2471 (Opacity) standards, ensuring uniform quality for sensitive printing and packaging uses.

ISO FDA-compliant FSC-certifiable

ISO FDA-compliant FSC-certifiable

What is Duplex Board Paper? Types & Technical Definitions

Duplex board paper refers to a two-layered paperboard: a high-quality surface (usually white, for printing/lamination) atop a core (grey, white, or brown-backed). It is classified by back color and coating type:

- Coated Duplex Board: Double/Single coated surfaces for enhanced print and ink holdout.

- Coated Duplex Board Grey Back: Economical, recycled core layer with a printable white top.

- Coated Duplex Board White Back: Both surfaces white, for premium aesthetics and food contact.

- Coated Duplex Board with Brown Back: Unique brown reverse, cleaner look, increased stiffness, improved recycling profile.

Technical Specifications Table: Duplex Board Paper vs. Main Alternatives

| Parameter | Duplex Board with Brown Back | Coated Duplex Board Grey Back | Duplex Board White Back | SBS (Solid Bleached Sulphate) |

|---|---|---|---|---|

| Grammage (gsm) | 230–450 | 230–550 | 230–450 | 170–400 |

| Thickness (mm) | 0.22–0.60 | 0.21–0.63 | 0.22–0.60 | 0.19–0.45 |

| Burst Strength (kPa) | 210+ (ISO 2759) | 200–250 | 210+ | 300+ |

| Stiffness (Taber, mNm) | 13–31 (ISO 2493) | 10–28 | 14–33 | 18–41 |

| Whiteness (ISO 11475) | 80% (top), 23% (back) | 72–75% (top), 40% (back) | 90%+ | 95%+ |

| Recycled Fiber Content | >80% | >85% | 60–80% | 0% |

| FDA Approval | Not Always | Depends | Available | Available |

| Typical Applications | Box, Food Outer Pack, Publishing | Toy, Shoe, General Packaging | Pharma, Cosmetics, Food Direct | All Premium Packaging |

Manufacturing Process of Duplex Board Paper: Step-by-Step Flow

- Pulping: Sourcing and refining recycled fibers & virgin pulp, achieving target Freeness and Consistency.

- Layer Formation: Twin-wire/formers lay top (white, printable) and bottom (brown/grey/white) plies with controlled layering.

- Press & Dry: Sheets dewatered (ISO 5263), compacted, and pressed for density, then dried via steam-heated cylinders.

- Surface Coating: Precision blade/bar coater applies pigment or polymer layers; target for ISO 536 coat weights 9–24 gsm. Ensures gloss, smoothness, and ink holdout.

- Calendering: Calendar stacks smooth and control board thickness (ISO 534).

- Slitting & Rewinding: Automated finish lines cut jumbo reels into sheets or smaller rolls; edge trimming for uniformity.

- Quality Checks: Random sampling per ISO 2471 (opacity), ISO 11475 (whiteness), and ANSI burst/tensile tests.

- Packing & Palletizing: Shrink-wrapped for moisture protection, labeled for batch traceability, stored before shipment.

Note: Duplex board with Brown Back additionally utilizes color sorting and enhanced deinking stages for its unique, eco-friendly reverse layer.

Process Visual: Schematic of duplex board paper production, from pulping to reel cutting.

▶ Video: Modern Duplex Board Mill Walkthrough

Key Features & Technical Advantages of Duplex Board Paper

- High Surface Strength: Minimizes linting and cracking in high-speed printing, meeting DIN 53121 standards.

- Customizable Coating: Single/double layer, for optimal ink absorption, gloss (85+%), and quick ink drying.

- Eco-Friendly: >80% recycled fiber content enables FSC certification and earns LEED credits for end-users.

- Superior Folding Endurance: ISO 5626-compliant, crucial for automated carton forming lines (20–150 folds min).

- Excellent Printability: Suits offset, flexo, digital, cup printing—no surface picking at recommended speeds.

- Moisture Resistance: Optional PE/anti-fungal treatments for frozen products or humid logistics chains.

- Dimensional Stability: Controlled shrinkage/expansion,

Manufacturers & Supplier Comparison

| Brand/Factory | Product Type | Min. Order (tons) | Coating Options | Certifications | Main Markets |

|---|---|---|---|---|---|

| Shineway Paper | Duplex board Brown/White/Grey Back | 16 | Single/Double | ISO 9001, FSC, SGS | Global (Focus: Asia/Pacific, Africa) |

| ITC (India) | Grey Back, White Back | 40 | Double, Triple | ISO, FDA | India, ME, Europe |

| Asia Pulp & Paper | Grey Back, White Back | 40 | Double | PEFC, ISO | Southeast Asia, Middle East |

| Mondi | SBS, White Back | 10 | Single/Double | FDA, FSC | Europe, America |

Why Choose Duplex Board with Brown Back?

- Cleaner reverse side minimizes contamination & dust during automated packing.

- Enhanced stiffness supports heavier loads—proven 20% improvement over standard grey back.

- Higher eco-ratings: achieved FSC Chain of Custody and meets REACH standards for harmful substances.

- Attractive price/performance ratio for both mass and luxury markets.

Customization & Supply Solutions

- Grammage Selection: 230–450 gsm standard; custom on request.

- Coating Formulation: Surface adapted for laser, offset, or flexo (with or without anti-microbial additives).

- Sheeting/Slitting: Sheets (390x545mm up to 1092x786mm+) or jumbo reels (650–2500mm width), ±2 mm tolerance.

- Printing Pre-treatment: Corona/plasma treatment available for digital applications.

- Packaging: Shrink-wrapped, kraft-wrapped, on Euro/US standard pallets; custom branding available.

- Logistics: Ex-works, FOB, CFR/CIF via multiple international ports; flexible lead times from 8–21 days.

Real-World Application Scenarios

Case Study 1: Instant Noodles Carton Packaging (Vietnam)

Challenge: Cost-optimized, food-compliant packaging for mass FMCG export, supporting high-speed automated packing lines.

Solution: Switched to duplex board with brown back (350 gsm), with FDA-compliant coating and antifungal treatment. Custom die-cut sheets improved machinability; 20% reduction in jams vs. previous grey-back.

Result: Cost Reduction: 13.5% Machining Uptime +11% | Customer Satisfaction +21%

Case Study 2: Electronics Box Printing (Europe)

Challenge: Rigid boxes for smartphones, requiring vivid color and surface smoothness, plus color-consistent reverse side.

Solution: Selected duplex board white back (400 gsm) for the outer sleeve; sample runs with duplex board brown back for inserts (sustainable inner packaging). Customized surface pigment helped achieve DeltaE <1.0 for Pantone colors.

Result: Tight print registration, eco-credentials (FSC), and inventory flexibility due to cross-compatible sizes.

Case Study 3: Pharma Blister & Leaflet Applications (Middle East)

Challenge: Product-specific boards with minimum migratory chemicals, optimal opacity, and smooth folding lines.

Solution: Adopted coated duplex board with grey back (280 gsm). Laser-checked for ISO 2470 opacity and porosity levels per client specs.

Result: Reduced failure rates by 8.7%, compliance with new FDA/EMA migration standards, delivered within 12 days from P.O.

Feedback & References

- Shoei Foods (Japan): “Switching to duplex board paper with brown back gave us more stable automated runs and cleaner box interiors.”

- AfriPrint (Ghana): “Consistent topcoat, zero blade clogging in high-speed offset presses. Print runs up to 1 million sheets – outstanding!”

- Med-Pack, Turkey: “Excellent folding performance and reliable GSM control, helped us meet strict pharma export audits.”

Frequently Asked Questions — Duplex Board Paper Technical FAQ

Q1: What is the fiber content composition of duplex board with brown back?

A: Typically, 80–95% recycled fiber (OCC, white waste) in the core layer; top ply uses high-purity (

Q2: Which international standards apply to coated duplex board for food packaging?

A: ISO 9001, ISO 536, ISO 2471 (grammage/opacity), FDA 21 CFR 176.170 (indirect food contact), and FSC Chain of Custody for sustainability.

Q3: What is the typical caliper/thickness tolerance?

A: ±3% of quoted caliper (e.g., for a 0.5 mm board, maximum variance is 0.015 mm); measured as per ISO 534.

Q4: How does surface sizing affect printability?

A: Double sizing (internal + surface) stabilizes ink absorption, controls dot gain, and prevents feathering in both offset and inkjet printing.

Q5: What burst strength is required for export cartons?

A: >50 kg/cm² (ISO 2759) is needed for export-grade folding cartons; duplex board with brown back typically exceeds 52 kg/cm².

Q6: Can I order water-resistant or freezer-grade duplex board?

A: Yes. PE-coated, moisture barrier duplex board is available; anti-fungal additive options for frozen/damp supply chains.

Q7: What is the typical lead time & MOQ?

A: Standard production: 8–14 days ex-works, MOQ from 16 tons (custom runs: 18–24 days). OEM sizing and branded packaging by request.

Delivery, Warranty & Customer Support

- Delivery Time: 8–14 days ex-works (Asia), 15–21 days for EU/NA destinations (FOB or CIF).

- Quality Guarantee: 100% replacement on non-conforming lots. Independent third-party SGS/BV inspection available.

- After-Sales: Process engineering support for print runs, supply chain optimization, and trouble-shooting.

- Free samples (A4 or custom cut) on request, including datasheets and printing test reports. Live video QC checks available.

- Contact: 24/7 online service at Shineway Paper

Conclusion & Industry Citations

Duplex board paper, and especially duplex board with brown back, is revolutionizing packaging economics and sustainability. Its technical versatility, supported by rigorous ISO/FDA standards and top-tier production control, makes it ideal for converters, printers, and end-users worldwide.

References & Further Reading:

[1] “Global Duplex Board Market Trends 2023,” Statista.

[2] “Printing & Conversion with Duplex Board,” Packaging Europe.

[3] Int’l Association of Paper, “ISO Standardization in Paperboards,” PaperNet Industry Forum.

[4] “Materials for Eco Packaging: A Comparative Study,” ResearchGate 2024.

Latest news

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025

-

Premium Duplex Board for Food Packaging & Printing

NewsJul.29,2025

-

Premium Decorative Base Paper for Melamine Surfaces & Furniture

NewsJul.28,2025