- Ikhaya

- The Versatility of Duplex Board and Printing Paper

Feb . 20, 2025 09:50 Buyela ohlwini

The Versatility of Duplex Board and Printing Paper

Double sided printer paper has become an essential product in both personal and commercial printing. This paper offers an efficient solution for printing on both sides, reducing paper usage and making it an eco-friendly option. Whether you're printing documents for an office, creating brochures for marketing, or producing a booklet, double sided printer paper allows you to maximize the space on each sheet, making it an ideal choice for large print runs or projects that require multiple pages.

Using double sided printer paper not only saves paper, but it also reduces the overall weight and volume of printed materials, which can lower shipping and handling costs. This type of paper also provides professional-quality printing on both sides, ensuring that your prints look sharp and clear. It’s an ideal choice for a variety of applications such as newsletters, flyers, and instruction manuals, where space optimization and cost-efficiency are crucial.

Understanding Both Side Printing Photo Paper

When it comes to high-quality photo printing, both side printing photo paper is a game-changer. Designed specifically for double-sided printing, this type of photo paper provides a smooth, glossy finish on both sides of the sheet, ensuring that your photos look vibrant and professional, whether they are printed on one side or both. This is especially useful for projects like photo albums, greeting cards, and promotional materials, where every side of the paper may need to display high-quality images.

The technology behind both side printing photo paper is tailored to prevent smudging or bleeding when printed on both sides. It’s engineered to allow ink to dry quickly while maintaining a rich color depth, ensuring that your photos appear crisp and vibrant. For photographers, artists, and marketers looking to produce photo books or double-sided marketing pieces, both side printing photo paper is a must-have product. It combines convenience with high-quality results, making it ideal for a variety of creative projects.

The Role of Coated Duplex Board Grey Back in Packaging

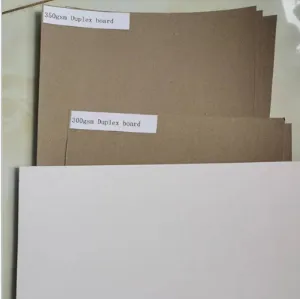

Coated duplex board grey back is a highly versatile material often used in packaging applications, particularly when strength and durability are important. This type of duplex board consists of two layers: a coated front that is smooth and perfect for printing, and a grey back that adds strength and rigidity to the material. Coated duplex board grey back is commonly used in the food and beverage packaging industry, as it provides an excellent balance of printability and structural integrity.

The coating on the front side of coated duplex board grey back makes it an ideal surface for high-quality printing, while the grey back ensures that the board maintains its strength and durability during handling and transportation. This material is often used in packaging for items such as cereals, frozen foods, and snack products, where the packaging must protect the contents while showcasing vibrant printed designs. The coated duplex board grey back offers an eco-friendly alternative to plastic-based packaging solutions, making it a popular choice for companies looking to reduce their environmental footprint.

Duplex Board Food Packaging: A Sustainable Solution

Duplex board food packaging is gaining popularity as a sustainable and cost-effective solution in the food industry. Made from high-quality duplex paperboard, this packaging material is durable, lightweight, and provides excellent protection for food products. Duplex board food packaging is often used for packaging dry food products such as snacks, biscuits, and ready-to-eat meals, where both protection and presentation are important.

The main advantage of duplex board food packaging is its ability to protect food items from external contaminants, while its smooth, printable surface allows for vibrant and eye-catching designs. Additionally, duplex board food packaging is biodegradable and recyclable, making it an eco-friendly alternative to plastic packaging. Brands and businesses in the food industry are increasingly turning to duplex board food packaging to meet consumer demand for sustainable packaging solutions without compromising on product quality or design.

The Versatility of Uncoated Duplex Board in Design and Printing

Uncoated duplex board is a versatile material that combines strength with a natural, rustic look. Unlike coated duplex boards, uncoated duplex board has a rougher surface, which gives it a more organic appearance. This type of board is widely used in various applications, including packaging, printing, and even in the production of greeting cards, business cards, and high-end invitations. The absence of coating allows for a more textured feel and provides an authentic look, which is highly valued in design-focused projects.

One of the benefits of using uncoated duplex board is its eco-friendly nature. This material is often made from recycled paper and is fully recyclable, making it an ideal choice for businesses aiming to reduce their environmental impact. Additionally, uncoated duplex board provides a more cost-effective solution for projects where high-end printing and visual appeal are required, but without the need for glossy finishes. This makes uncoated duplex board a popular choice for businesses looking to balance sustainability with budget constraints while still producing aesthetically pleasing and functional designs.

From the cost-efficient double sided printer paper to the highly durable coated duplex board grey back and eco-friendly duplex board food packaging, the versatility of these materials has revolutionized industries ranging from printing to packaging. Each material, whether it’s the smooth surface of both side printing photo paper or the organic texture of uncoated duplex board, offers unique advantages depending on the application. Businesses today are increasingly aware of the environmental impact of their choices, and materials like duplex board are providing a sustainable yet functional solution for a variety of uses. Whether you're printing high-quality photos, creating food packaging, or designing custom cards, the right paper can elevate your product while helping you reduce your environmental footprint.

Izindaba zakamuva

-

White Contact Paper for Cabinets – Transform Your Kitchen

IzindabaJun.13,2025

-

Duplex Board Paper: Properties and Manufacturing Process

IzindabaJun.13,2025

-

Food Packaging Solutions: Why Duplex Board is a Top Choice

IzindabaJun.13,2025

-

Best Types of Furniture Decoration Paper

IzindabaJun.13,2025

-

What Are the Best Adhesives for Applying Furniture Decoration Paper?

IzindabaJun.09,2025

-

Key Properties and Uses of Duplex Board Paper in Packaging

IzindabaJun.09,2025