- Home

- Duplex Board with Gray back

Jan . 13, 2025 16:10 Back to list

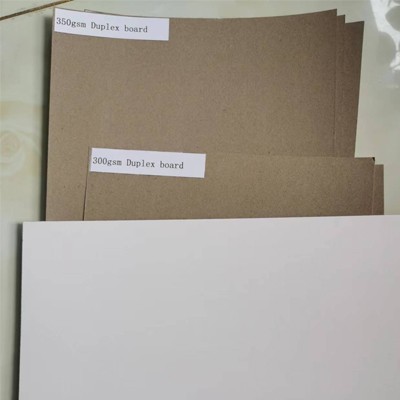

Duplex Board with Gray back

The intricate process of wholesale duplex paper manufacturing combines expertise, precision, and technological innovation to create a versatile product widely used across multiple industries. Duplex paper, characterized by its two distinct layers, is valued for its rigidity, strength, and high print quality, making it an ideal choice for packaging, printing, and various commercial applications.

After calendaring, the paper is typically coated to enhance its printability. Coating materials, which may include kaolin clay, calcium carbonate, or other proprietary blends, are meticulously applied to one or both sides of the paper surface. This coating not only improves the paper's aesthetic appeal and printing capabilities but also augments its durability and resistance to moisture. The process is carefully monitored by experts who leverage their specialized knowledge to achieve the perfect balance between functionality and visual appeal. Sustainability is a core focus in modern duplex paper manufacturing. Besides sourcing materials responsibly, manufacturers employ energy-efficient technologies and water recycling practices to mitigate environmental impact. Advanced pollution control systems are installed to ensure that emissions are minimal and within regulatory guidelines. By embracing sustainable practices, manufacturers not only contribute positively to the environment but also build trust with clients and consumers who prioritize eco-friendly products. As the last stage in the process, the duplex paper is subjected to rigorous testing to confirm its strength, opacity, weight, and other essential characteristics. Leading manufacturers offer customizable options, allowing clients to specify parameters such as thickness, coating type, and color. This level of customization underscores the manufacturer's commitment to expertise and meeting market demands with precision. In essence, the wholesale duplex paper manufacturing process is a testament to the intersection of expertise, innovation, and responsibility. Its successful execution relies on skilled professionals who bring technical knowledge and real-world experience to the forefront, ensuring that each product not only meets quality expectations but also aligns with environmental stewardship principles.

After calendaring, the paper is typically coated to enhance its printability. Coating materials, which may include kaolin clay, calcium carbonate, or other proprietary blends, are meticulously applied to one or both sides of the paper surface. This coating not only improves the paper's aesthetic appeal and printing capabilities but also augments its durability and resistance to moisture. The process is carefully monitored by experts who leverage their specialized knowledge to achieve the perfect balance between functionality and visual appeal. Sustainability is a core focus in modern duplex paper manufacturing. Besides sourcing materials responsibly, manufacturers employ energy-efficient technologies and water recycling practices to mitigate environmental impact. Advanced pollution control systems are installed to ensure that emissions are minimal and within regulatory guidelines. By embracing sustainable practices, manufacturers not only contribute positively to the environment but also build trust with clients and consumers who prioritize eco-friendly products. As the last stage in the process, the duplex paper is subjected to rigorous testing to confirm its strength, opacity, weight, and other essential characteristics. Leading manufacturers offer customizable options, allowing clients to specify parameters such as thickness, coating type, and color. This level of customization underscores the manufacturer's commitment to expertise and meeting market demands with precision. In essence, the wholesale duplex paper manufacturing process is a testament to the intersection of expertise, innovation, and responsibility. Its successful execution relies on skilled professionals who bring technical knowledge and real-world experience to the forefront, ensuring that each product not only meets quality expectations but also aligns with environmental stewardship principles.

Latest news

-

Removable Contact Paper for Kitchen Cabinets - Durable, Easy to Install, Stylish Designs

NewsJun.24,2025

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025

-

Premium Contact Paper for Table Top - Durable, Easy to Apply, Stylish Surfaces

NewsJun.10,2025

-

Contact Paper to Cover Dresser Durable & Easy Application

NewsJun.10,2025

-

Top Dresser Drawer Contact Paper Suppliers Waterproof & Durable Liner

NewsJun.10,2025

-

Premium Desk Wall Paper Suppliers Export & Manufacture

NewsJun.09,2025