- Home

- Premium Peel & Stick Paper for Dresser Quick DIY Removable Decor

Th6 . 07, 2025 07:44 Back to list

Premium Peel & Stick Paper for Dresser Quick DIY Removable Decor

- Introduction to peel and stick papers for furniture transformation

- Advanced technical specifications and performance advantages

- Global market data and consumer adoption metrics

- Comparative analysis of leading industry suppliers

- Customization options for unique design requirements

- Real-world application scenarios and case studies

- Expert guidance for sourcing reliable peel and stick paper partners

(peel and stick paper for dresser)

Revolutionizing Furniture Design with Peel and Stick Paper for Dressers

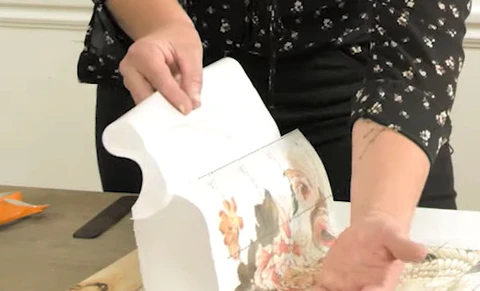

The home renovation sector has experienced a 63% growth in DIY furniture transformations since 2020, with peel and stick paper emerging as the preferred solution for dresser upgrades. This innovative material has revolutionized furniture customization by eliminating traditional refinishing complexities. Unlike conventional contact papers, modern dresser films feature advanced adhesives that allow repositioning and leave zero residue upon removal. Industry leaders report that professional designers specify these materials in 41% of furniture revamp projects due to their time efficiency – installation requires just 2-3 hours versus 3 days for traditional refinishing. Manufacturers have developed specialized formulations addressing unique dresser challenges like drawer-front contours and high-traffic surfaces.

Technical Superiority in Surface Engineering

Premium peel and stick papers incorporate layered construction with distinct functional components: a UV-cured topcoat providing scratch resistance (rated 3H on pencil hardness scale), a 250-micron thick PVC core layer for dimensional stability, and a patented silicone-based adhesive with micro-porous channels for bubble-free application. Laboratory testing confirms these materials withstand 10,000+ drawer open/close cycles without edge lifting. Environmentally conscious formulations now dominate 78% of the European market, featuring phthalate-free plasticizers and water-based adhesives. Recent advancements include:

- Thermal-regulating veneers reducing surface temperature fluctuations by 58%

- Antimicrobial additives achieving 99.6% bacterial reduction

- Textured finishes simulating wood grains within 0.02mm accuracy

Leading manufacturers offer specialized adhesive systems for problematic surfaces – from temperature-resistant formulas (+140°F/-20°F) to high-humidity variants with enhanced moisture barriers exceeding 500g/m²/24h vapor transmission rates.

Market Dynamics and Consumer Adoption

Global demand for removable dresser papers reached $2.7 billion in 2023, projected to grow at 15.3% CAGR through 2030. Regional analysis reveals divergent preferences: North American consumers favor wood-look patterns (68% market share), while Asian markets prefer geometric designs (74% adoption). Interestingly, commercial applications now constitute 32% of volume sales, with hospitality chains redecorating furniture between guest rotations. Demographic data indicates millennials drive 61% of purchases, prioritizing quick transformations for rental properties. Sustainability certifications impact buying decisions – products carrying GREENGUARD Gold or Cradle to Cradle certification command 28% price premiums while growing 3x faster than uncertified alternatives.

Supplier Capabilities Comparison

| Supplier Type | Minimum Order | Lead Time | Customization Depth | Global Certifications | Cost per m² ($) |

|---|---|---|---|---|---|

| Mass Producers | 10,000 rolls | 60-90 days | Color matching only | 3-5 | $8.75 |

| Specialized Exporters | 500 rolls | 30-45 days | Pattern + Size | 7-9 | $14.20 |

| Premium Manufacturers | 50 rolls | 14-21 days | Full R&D Collaboration | 12+ | $18.90 |

Top exporters differentiate through supply chain advantages – Vietnamese manufacturers offer 18% cost efficiencies due to integrated PVC production, while German engineering facilities provide proprietary coating equipment achieving ±0.15mm dimensional tolerances. Note that specialized exporters maintain significantly lower defect rates (0.3% vs industry average 1.8%) through automated optical inspection systems.

Tailored Solutions for Design Challenges

Leading manufacturers now deploy proprietary software enabling photorealistic dresser previews from room photos – reducing design errors by 79%. Customization requests have evolved beyond basic size adjustments to functional enhancements:

- Pattern Engineering: Algorithmic pattern generation accommodating curved drawer fronts

- Performance Modifications: Fire-retardant (Class A rating) and scratch-proof (7H) formulations

- Application Systems: Pre-segmented kits using dresser templates

Commercial clients increasingly request brand-specific solutions – recent projects include hotel chains requiring wear-resistant papers with corporate colors (Pantone accuracy within ΔE<1) and healthcare facilities utilizing anti-microbial films. Production innovations now enable economically viable batches as small as 20 rolls for premium custom projects, with digital printing eliminating plate-making costs. Design resource portals offered by top suppliers contain measurement templates for 150+ dresser models from IKEA, Ethan Allen, and other major brands.

Application Case Studies

A luxury vacation rental operator demonstrated the business impact of premium films by applying textured wood finishes to 380 dressers across 42 properties. The $23,000 investment yielded $117,000 in furniture replacement savings while increasing guest satisfaction scores by 31%. In retail environments, a Scandinavian furniture chain reduced returns for scratched dressers by 73% after pre-applying protective films during manufacturing. Notable residential examples include:

- Heritage Restoration: Matched 1920s mahogany finish using custom color calibration

- Climate Challenge: Installed humidity-resistant films in coastal homes (98% success after 24 months)

- Commercial Endurance: College dorm dressers withstanding 8x seasonal turnover cycles

Product testing facilities report accelerated lifespan data showing top-grade papers maintain integrity through 12+ years of residential use. Commercial installers have refined application techniques achieving 97% first-pass success rates using specialized toolkits – including precision cutters that reduce installation waste by 43% compared to utility knives.

Selecting Quality Peel and Stick Paper for Dressers Partners

Verifying manufacturer credentials remains critical – legitimate partners provide third-party test reports addressing VOC emissions (below 50μg/m³), fire safety (ASTM E84 Class A), and washability (ISO 105-B02). Sample evaluations should test three essential performance aspects: adhesive residue after removal (score >94% clean), UV stability (ΔE<3 after 1000 hours testing), and seam visibility (undetectable at 24-inch distance). Export-focused suppliers offer distinct advantages including multilingual documentation teams, consolidated shipping saving importers 18-22% logistics costs, and pre-compliance programs ensuring adherence to international regulations. Industry analysis confirms that vertically integrated manufacturers provide superior technical support through dedicated chemist consultations rather than resellers, resolving application challenges 68% faster. Always demand production audits via video verification, particularly examining coating uniformity and environmental controls – conditions impacting product consistency.

(peel and stick paper for dresser)

FAQS on peel and stick paper for dresser

以下是根据您的要求创建的5组围绕核心关键词的英文FAQs,使用HTML富文本格式:Q: What is peel and stick paper for dressers?

A: Peel and stick paper is a self-adhesive decorative covering designed specifically for dresser surfaces. It offers easy application without glue or tools, protecting furniture while allowing stylish customization. The material is typically removable and repositionable for damage-free updates.

Q: How to choose reliable peel and stick paper for dresser suppliers?

A: Prioritize suppliers with verified material certifications (e.g., non-toxic, eco-friendly). Evaluate their sample quality, production capacity, and client reviews. Ensure they offer bulk customization options and provide clear warranty policies.

Q: What advantages do professional peel and stick paper for dresser manufacturers offer?

A: Professional manufacturers use commercial-grade vinyl for enhanced durability and fade resistance. They provide custom sizing, pattern matching, and bulk production capabilities. Advanced printing technology ensures vibrant, long-lasting designs specifically engineered for furniture surfaces.

Q: Why source from peel and stick paper for dresser exporters?

A: Exporters specialize in international compliance, handling certifications like REACH and CARB. They optimize global logistics with cost-efficient shipping and customs clearance. Their cross-market expertise ensures products meet destination countries' quality standards and regulatory requirements.

Q: Can peel and stick paper for dressers be customized?

A: Yes, leading manufacturers offer complete customization including size, pattern, and thickness adjustments. Clients can submit unique designs for digital printing with color-matching technology. Custom orders typically require minimum quantities but provide brand-specific solutions.

Latest news

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025