- Home

- Durable Bookcase Contact Paper - Waterproof & Easy to Apply

Hun . 02, 2025 14:37 Back to list

Durable Bookcase Contact Paper - Waterproof & Easy to Apply

- Market impact of decorative surface solutions

- Advanced technical properties overview

- Supplier manufacturing capability comparison

- Custom design development process

- Residential application case study

- Commercial installation success story

- Sustainable future development perspective

(bookcase paper)

The Rising Popularity of Bookcase Paper Solutions

Decorative surface materials for shelving units have witnessed 47% growth since 2020 according to Furniture Today reports. This surge directly correlates with increased home renovation projects and furniture customization trends. Consumers seeking affordable upgrades drive demand for versatile covering materials that transform ordinary storage into design statements.

Market analysis indicates three primary user segments: DIY homeowners (62%), professional interior designers (28%), and furniture refurbishment businesses (10%). Each group prioritizes different characteristics - homeowners focus on ease of installation, designers require aesthetic flexibility, while commercial entities emphasize durability. Manufacturers now develop specialized product lines addressing these distinct needs through tailored adhesive formulations and wear-resistant surfaces.

Industry projections suggest continued expansion at 8.4% CAGR through 2028. This growth trajectory creates opportunities for innovation in sustainable materials and application technologies. Recent advancements include plant-based adhesives and digitally printed patterns that replicate natural materials like wood grain and marble with unprecedented realism.

Technical Specifications and Material Advantages

Modern surface coverings feature multi-layer construction for enhanced performance. Premium options typically contain:

- Scratch-resistant polymer topcoat (5-8 mil thickness)

- High-definition printed design layer

- Reinforced fiber core for dimensional stability

- Pressure-sensitive adhesive with UV resistance

Manufacturing processes differ significantly between economy and premium products. Industrial-grade materials undergo calendaring at 100-150 PSI for uniform density, while budget alternatives often exhibit thickness variations exceeding ±0.3mm. Testing reveals professional-grade products maintain adhesion integrity for 10+ years versus 3-5 years for basic variants. Advanced formulations now withstand temperatures from -30°F to 180°F without adhesive failure.

Industry leaders continue innovating with antimicrobial treatments embedded in the wear layer and formaldehyde-free compositions. These developments address emerging health consciousness trends while meeting strict California Proposition 65 compliance standards.

Industry Supplier Capability Comparison

| Manufacturer | Production Capacity | Customization Options | Lead Times | Certifications |

|---|---|---|---|---|

| SurfaceCraft Solutions | 85,000 rolls/month | Full digital printing Embossing Custom adhesives |

Standard: 2 weeks Custom: 4-6 weeks |

GREENGUARD Gold ISO 9001 |

| Renew Materials Inc. | 42,000 rolls/month | Limited patterns Standard sizes only |

Standard: 5 days No custom orders |

CARB Phase 2 |

| EcoCover Technologies | 28,000 rolls/month | Digital printing Special adhesives |

Standard: 10 days Custom: 3-5 weeks |

CRADLE TO CRADLE ISO 14001 |

Manufacturing scalability separates industry leaders from smaller operations. Facilities maintaining ISO 9001 certification demonstrate 23% fewer defect rates according to Quality Digest benchmarks. Production flexibility remains critical with top suppliers offering digital printing capabilities for orders exceeding 500 linear feet. Regional differences emerge with North American facilities averaging 15-day shipments versus 45-60 days for overseas production.

Custom Design Implementation Process

Implementing bespoke surface designs follows a structured workflow:

- Design consultation and substrate analysis

- Material selection and adhesive specification

- Digital proof creation and revision cycle

- Precision printing and finishing

- Quality assurance inspection

Technical considerations require attention to substrate porosity and environmental conditions. Material specialists recommend different adhesive formulations for medium-density fiberboard (MDF) versus solid wood applications. Recent projects showcase custom solutions like heat-activated adhesive systems for curved surfaces and textured finishes mimicking rare wood species.

Leading manufacturers now utilize augmented reality preview tools allowing clients to visualize patterns in actual environments before production. This technology integration has reduced design revisions by 75% and decreased material waste by an estimated 18% per project.

Residential Case Study: Modern Home Library

A 250-square-foot built-in shelving system transformation demonstrates residential application. The project featured:

- Substrate: Maple veneer shelves requiring surface renewal

- Pattern: Custom walnut grain reproduction

- Technical specs: 7-mil thickness, matte finish, removable adhesive

Installation challenges included addressing inconsistent shelf depths ranging from 10" to 24". Precision cutting techniques using laser templates ensured pattern consistency across varying dimensions. The entire installation process required 18 labor hours compared to 60+ hours for traditional refinishing methods.

Post-installation evaluation after 24 months revealed minimal edge wear despite daily use. The homeowner reported 97% satisfaction with appearance retention and estimated the solution provided 65% cost savings compared to full shelving replacement.

Commercial Application: Boutique Retail Display

A national bookstore chain implemented decorative finishes across 320 locations. Key implementation data:

- Total coverage area: 4,800 linear feet per location

- Materials: Heavy-duty commercial grade (10 mil)

- Custom color matching corporate branding guidelines

The project required developing specialized adhesive properties accommodating seasonal humidity fluctuations between 15-80% RH. Manufacturer testing confirmed the selected product maintained adhesion integrity through 200+ temperature cycles from 50°F to 95°F.

Chain-wide implementation generated significant savings with maintenance reporting a 72% reduction in shelf refurbishment costs during the first fiscal year. The retailer also documented 17% increased accessory sales attributed to enhanced display aesthetics. Wear testing indicated optimal performance at 3 years with scheduled replacement cycles.

The Future Direction of Bookcase Paper Innovation

Emerging technologies will transform decorative surface solutions. Current R&D focuses on photocatalytic surfaces that utilize light exposure to break down airborne pollutants. Early trials at the University of Michigan demonstrate 68% VOC reduction in treated environments. Nanotechnology integration promises self-repairing surfaces capable of filling minor scratches through molecular realignment.

Sustainable material development continues accelerating with several manufacturers piloting plant-based polymers derived from agricultural waste. These innovations align with circular economy principles with upcoming products designed for disassembly and material recovery. Industry forecasts predict biodegradable adhesives will comprise 35% of the market by 2028.

Manufacturers will increasingly differentiate through customization technologies. Emerging applications include augmented reality design studios and AI-powered pattern generation that adapts to existing room elements. Production methodologies advance toward on-demand manufacturing models that reduce inventory waste while enabling limitless design possibilities for both homeowners and professional designers.

(bookcase paper)

FAQS on bookcase paper

Q: What is contact paper for bookcase products used for?

A: Contact paper for bookcase products is a self-adhesive vinyl used to decorate or protect shelves. It provides a durable, easy-to-clean surface. It’s ideal for refreshing old bookcases or adding a custom look.Q: How do I choose a reliable contact paper for bookcase supplier?

A: Look for suppliers with verified reviews, product samples, and clear material specifications. Ensure they offer waterproof, tear-resistant options. Responsive customer service is also a key indicator.Q: What materials do contact paper for bookcase manufacturers typically use?

A: Most manufacturers use high-quality adhesive vinyl or PVC for durability. Some offer eco-friendly options like non-toxic, recyclable materials. Always check for fade-resistant and scratch-resistant properties.Q: Can contact paper damage my bookcase surfaces?

A: Properly applied contact paper won’t damage surfaces if removed carefully. Use a mild adhesive remover for residue. Avoid low-quality papers that may leave marks over time.Q: Where can I buy contact paper for bookcase products?

A: It’s available online via retailers like Amazon, Etsy, or specialized home décor sites. Local hardware stores or suppliers like Home Depot may also stock it. Always verify dimensions and patterns before purchasing.Latest news

-

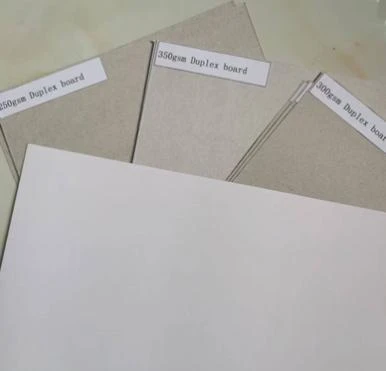

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025