- Home

- duplex coated board manufacturer

Oct . 30, 2024 14:53 Back to list

duplex coated board manufacturer

Understanding Duplex Coated Board Manufacturers An Overview

In the ever-evolving world of packaging and printing, duplex coated board has emerged as a pivotal material for various applications. Renowned for its versatility and sustainability, duplex coated board is extensively used in making boxes, cartons, and various other packaging solutions. As the demand for high-quality packaging solutions continues to grow, the role of duplex coated board manufacturers is increasingly significant.

What is Duplex Coated Board?

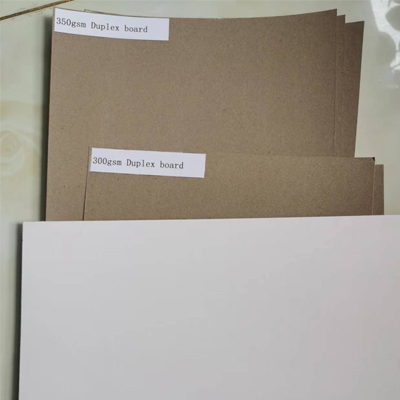

Duplex coated board is a type of paperboard that is made from two layers of pulp and coated with a layer of clay on one or both sides. This coating not only provides a smooth surface for printability but also enhances the board's durability and rigidity. The two primary types of duplex boards are gray back and white back boards. Gray back duplex board has a grayish underside, which is cost-effective and frequently used for packaging less premium products. In contrast, white back duplex board has a pristine white underside, making it ideal for high-quality printing applications, such as food packaging or luxury goods.

The Manufacturing Process

The manufacturing of duplex coated board involves multiple stages. Initially, wood chips are turned into pulp through mechanical and chemical processes. This pulp is then refined and blended to achieve the desired consistency and quality. Once the pulp is ready, it is formed into sheets and passed through large machines that apply a coating of clay or other materials. This coating process is crucial as it enhances the surface properties, making the board suitable for high-quality printing.

After coating, the sheets are dried and cut into desired sizes. Quality control is an integral part of the manufacturing process, ensuring that each sheet meets industry standards for thickness, smoothness, and color consistency. Duplex coated board manufacturers often employ advanced technology to monitor the production process, guaranteeing quality and efficiency.

duplex coated board manufacturer

Market Trends and Sustainability

With increasing awareness of environmental issues, sustainability has become a significant factor in the manufacturing of duplex coated boards. Many manufacturers are now adopting eco-friendly practices, such as using recycled fibers and water-based coatings instead of traditional solvent-based ones. This shift not only helps reduce the environmental impact but also appeals to consumers who prefer sustainable packaging options.

Moreover, the rise of e-commerce and online shopping has created a surge in demand for high-quality packaging materials. As businesses seek ways to enhance their brand image and ensure product safety during shipping, duplex coated boards are becoming an increasingly popular choice.

Challenges Faced by Manufacturers

Despite the growing demand, duplex coated board manufacturers face several challenges, including fluctuating raw material prices, stringent regulations concerning environmental impacts, and the need for continuous innovation to meet market trends. Additionally, the competition in the packaging industry is fierce, pushing manufacturers to invest in research and development to create superior products that cater to diverse customer needs.

Conclusion

Duplex coated board manufacturers play a crucial role in the packaging and printing sectors by providing high-quality, versatile, and sustainable materials. As the industry continues to evolve, embracing innovation and sustainability will be key for manufacturers to thrive in a competitive market. By understanding the dynamics of duplex coated board production and market trends, these manufacturers can better position themselves to meet the increasing demands of consumers and businesses alike.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025