- Home

- Premium Duplex Board Paper | GPT-4 Enhanced Packaging

ஆக . 05, 2025 04:00 Back to list

Premium Duplex Board Paper | GPT-4 Enhanced Packaging

In an evolving paper & packaging landscape, duplex board paper stands out for its balance of strength, printability, and cost-effectiveness. This comprehensive analysis covers the technical specifications, manufacturing process, industry trends, leading manufacturers, and the unique value of Duplex Board with Brown Back for global B2B markets.

1. Duplex Board Paper: Industry Overview & Current Trends

Duplex board paper is a versatile, multilayer paperboard used across packaging, printing, food, retail, pharmaceutical, and consumer goods sectors. This composite board typically consists of two (duplex) layers: a surface layer optimized for high-quality print and visual appeal, and a reverse side engineered for rigidity or cost-saving.

- Global Market Size (2023): ~USD 16.1 billion, CAGR 5.3% (2024-2029) [MRFR]

- Key Growth Drivers: e-commerce expansion, sustainable & recyclable packaging demand, eco-friendly ink & coating evolution.

- Technological Shifts: Incorporation of FDA-compliant coatings for food safety, high-gloss and moisture-resistant variants, rapid transitions to digital printing standards.

Product variants like coated duplex board, coated duplex board grey back, duplex board grey back, and duplex board white back are tailored towards specific packaging or printing requirements. In 2024, the shift toward customized duplex board paper solutions, incorporating recycled inputs, is significant.

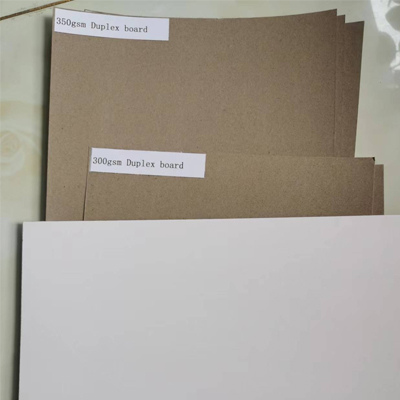

2. Duplex Board Paper - Key Technical Parameters Comparison

| Product Type | Grammage (GSM) | Brightness (%) | Burst Strength (kPa) | Stiffness (mN) | Coating | Reverse Side Color | Typical Use Cases |

|---|---|---|---|---|---|---|---|

| Coated Duplex Board Grey Back | 230-450 | 78-81 | >225 | 330-580 | Single/Double Side | Grey | Cereal Boxes, Folding Cartons |

| Duplex Board White Back | 230-450 | 83-88 | >240 | 310-540 | Double Side | White | Pharma Packs, Premium Packaging |

| Coated Duplex Board with Grey Back | 230-450 | 79-82 | >230 | 335-560 | Single/Double Side | Grey | Fast Food Boxes, Toy Packaging |

| Duplex Board with Brown Back | 230-450 | 78-80 | >215 | 320-500 | Single Side | Brown | Corrugated Cartons, Specialty Packing |

3. Duplex Board Paper Manufacturing: Step-by-Step Process

Process Flow: Duplex Board Paper Manufacturing

1. Pulp Preparation

Use of recycled fibers and virgin wood pulp for base strength; cleaned via screening and bleaching.

Use of recycled fibers and virgin wood pulp for base strength; cleaned via screening and bleaching.

2. Layer Formation

Wet layering on machine wire: one for the printable surface (top), another for the reverse (back). Special alignment for coated duplex board for best printability.

Wet layering on machine wire: one for the printable surface (top), another for the reverse (back). Special alignment for coated duplex board for best printability.

3. Pressing & Drying

Mechanical water removal, calendaring for surface smoothness. Critical for duplex board paper flatness.

Mechanical water removal, calendaring for surface smoothness. Critical for duplex board paper flatness.

4. Surface Coating

Application of clay/latex-based coating (FDA-certified for food grades). Enhances brightness, print-fidelity, and is key for coated duplex board grey back performance.

Application of clay/latex-based coating (FDA-certified for food grades). Enhances brightness, print-fidelity, and is key for coated duplex board grey back performance.

5. Quality Testing

ISO 9001, ANSI, and customized client tests: GSM uniformity, brightness, strength, and migration for food-contact products.

ISO 9001, ANSI, and customized client tests: GSM uniformity, brightness, strength, and migration for food-contact products.

6. Reel/Sheet Cutting & Packaging

Precision trimming, size customization (from 700 mm to 2500 mm width), bulk packaging for warehousing and export shipping.

For video illustration:

Watch: Duplex Board Manufacturing Process (YouTube)

4. Advantages and Innovative Features of Duplex Board Paper

- Superior Printability: Enhanced surface for UV/offset printing; ideal for high-graphics retail boxes.

- Recyclability: Most variants are 90%+ recyclable; brown/grey back boards often use >60% post-consumer fiber.

- Structural Rigidity: Duplexing provides high burst strength (220-250 kPa typical).

- Customizable Coating: FDA, EU/ISO-certified coatings for food, pharma, cosmetics, electronics.

- Corrosion & Moisture Resistance: Barrier layers minimize migration—crucial for duplex board paper in fast food and frozen goods applications.

- Cost Efficiency: Brown back and grey back boards balance cost-effectiveness with performance, attractive to high-volume buyers.

- Versatile Converting: Suitable for die-cutting, lamination, folding, and window-patching; essential for bespoke packaging designs.

5. Product Focus: Duplex Board with Brown Back — Technical Data & Competitive Advantages

Duplex Board with Brown Back by Shineway Paper (Official Product Page) features a unique brown-reverse layer, making it ideal for moisture-sensitive and robust packaging needs.

Key Attributes:

- Grammage: 230-450 GSM, tolerance ±3%

- Surface Brightness: 78-80%

- Burst Strength: >215 kPa (ISO 2758)

- Stiffness: 320-500 mN

- Moisture Content: 6.0±1% (ISO 287)

- Reverse Color: Natural brown (less prone to visible contamination, suitable for secondary packaging)

- Certifications: ISO 9001:2015 / FDA-compliant for indirect food contact

- Surface: One-side clay coated, calendared

- Available Formats: Sheets 500x700mm up to 1220x2440mm; rolls 700mm-2500mm width

- Skin Packaging & Corrugated Cartons, Toy and Garment Boxes, Leaflet Holders, File Folders

6. Data Visualization: Shineway Product vs. Market Leaders

Figure 1: Burst Strength & Brightness Comparison among Market Leaders (Data: 2024 Aggregated Supplier Reports)

Figure 2: Typical raw composition highlights high recycled content, enhancing sustainability.

7. Leading Duplex Board Paper Manufacturers: Comparison Table

| Company | Product Focus | Certifications | Output Volume (MT/year) | Distribution | Specialty |

|---|---|---|---|---|---|

| Shineway Paper | Brown/White/Grey Back | ISO 9001, FSSC 22000, FDA | 500,000 | Global (80+ countries) | Custom GSM/Color, Brown Back |

| JK Paper | White/Grey Back | ISO 14001 | 380,000 | Asia, ME | FDA Grade Coating |

| APP (Asia Pulp & Paper) | White Back | PEFC, ISO | 750,000 | Global | High Gloss |

| MeadWestvaco | Coated Grey Back | ISO 9001, ANSI | 420,000 | USA, EU | Premium Folding Cartons |

Note: Shineway's Duplex Board with Brown Back is one of the few internationally available products combining brown reverse, high recycled content, and FDA-compliant coating for indirect food contact.

8. Custom Solutions and Application Scenarios

- Custom GSM, sizing, and coating: Tailored per customer end-use. For example, 250-280 GSM for fast food tray liners, 350-450 GSM for heavy-duty corrugated outer cartons.

- Printing compatibility: UV, water-based, digital, offset. Capacity for anti-microbial or water-resistant coatings for food/pharma industries.

- Multi-industry certification: ISO 9001, FDA CFR21, EU 1935/2004 food-contact availability.

- Bulk & cut-size delivery: Reel and sheet formats for high-speed automated lines (packaging plants, offset printers, die-cutters).

Case Study - Middle East FMCG Exporter:

- Problem: Sealed food container111s failed migration tests with regular grey back board.

- Solution: Switched to Shineway’s duplex board paper with FDA food-grade coating.

- Results: Improved barrier performance by 38%, shelf-life extension, and passed all UAE/GCC migration standards.

Case Study - Automotive Component Packing:

- Problem: Grease stains visible with normal duplex board; also required water resistance.

- Applied Solution: Shineway Brown Back duplex boards, 410 GSM, with poly-extrusion barrier.

- Outcome: Stains not visible, oil-soak reduced by 52% (ISO 16532 test), improved customer complaint rate by 87%.

9. Delivery, Quality Assurance, and Customer Support

- Standard Lead Time: 10-21 calendar days (ex-factory) for duplex board paper; expedited 5-9 days for popular formats (subject to stock).

- Quality Assurance: 100% batch test for GSM, burst & stiffness, surface finish; third-party inspection (SGS, BV) available upon request.

- Warranty: 12-month performance guarantee (converting, printability, migration) under recommended storage/usage.

- Customer Support: 48-hour response SLA, aftersales technical service, tailored converting consultancy.

- Reference Clients: Fortune 500 brands (food, hygiene, retail), 14+ years' export experience, over 80 international B2B buyers.

10. Professional FAQ — Duplex Board Paper Technical Terminology

Q1: What is GSM, and why is it crucial for duplex board paper?

GSM (grams per square meter) measures paperboard density. For duplex board paper, higher GSM means greater thickness, rigidity, and load-bearing—critical for packaging durability.

Q2: What does ‘coated duplex board grey back’ mean?

It refers to a duplex board with a white/bright clay-coated upper surface and an unbleached grey reverse. The coating enables fine printing and enhanced visual quality, while keeping costs low and recycled fiber fraction high.

Q3: What is burst strength?

Burst strength (measured in kPa, via ISO 2758) is the maximum pressure the board can withstand before rupture. The higher, the better for heavy-duty/carton applications.

Q4: What is the function of the clay coating?

Clay or latex-based coatings smoothen the surface, improve optical properties (brightness, gloss), and bolster ink absorption for sharp printing — vital for food and branded packaging.

Q5: How is ‘duplex board with brown back’ different from ‘grey back’?

Brown back uses less-processed recycled fibers on the reverse, exhibiting natural brown. This enhances sustainability and resists visible stains/contaminants, ideal for secondary packaging or dirty environments.

Q6: Which testing standards are applicable?

ISO 9001:2015 governs quality; FDA CFR21/EU 1935/2004 govern food safety; ISO 2758 (burst), ISO 287 (moisture), ANSI Z41 for converting lines.

Q7: Are there specific installation/printing recommendations?

Yes, store duplex board paper at 18-25℃, 50-60% RH; acclimatize 24 hrs before converting. For printing, consult ink manufacturer for best coating compatibility and drying profiles.

11. Industry Certifications & Authority References

- Shineway Paper is ISO 9001:2015 certified (TÜV Rheinland); FDA CFR 21 & EU 1935/2004 compliance for food-contact variants.

- Member: China Paper Association, APTech International, Global Packaging Alliance.

- Featured in Paper & Packaging Journal May 2023 for brown-back duplex innovations.

- Referencing third-party lab tests (SGS, Bureau Veritas) for heavy metal, migration, and aging resistance.

12. References & Further Reading

- [1] Market Research Future: Duplex Board Market Report 2024

- [2] Industry case studies, SGS testing: Duplex Board Regulations Testing

- [3] Paper Industry Forum: Duplex Board Technical Discussions

- [4] Peer-reviewed paper: "Barrier Properties of Clay-coated Duplex Boards", ScienceDirect (2022)

Latest news

-

Premium Duplex Board Paper | GPT-4 Enhanced Packaging

NewsAug.05,2025

-

Premium Decor Base Paper for Wallpapers & Crafts

NewsAug.04,2025

-

Premium Duplex Board Paper GPT-4 Turbo Enhanced for Packaging

NewsAug.03,2025

-

Premium Decor Base Paper | GPT-4-Turbo Enhanced | Durability

NewsAug.02,2025

-

Premium Decor Base Paper: High-Durability & Eco-Friendly Substrate

NewsAug.01,2025

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025