Вести

-

Tips to Choose Decorative Paper For Furniture

There are different types of decorative paper available for furniture. You can choose from ornate papers, painted decor papers, PU decorative foil paper, and wood contact paper. Read this article to find out more. We have listed the different types of decorative papers and the different types of furniture they are ideal for. The following are a few tips for choosing the right type for your home. And don’t forget to experiment with the different options!Опширније -

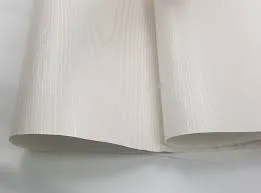

INTRODUCTION OF MELAMINE PAPER

Melamine paper is a kind of decorative paper for composite wood board (for furniture), flooring etc, plays an important role for home decor and mall decor, you can find melamine paper products everywhere. Difference from the finish paper foil, the melamine paper sheet without texture design on the surface, is formed by dipping the printed in the melamine resin. Therefore, the melamine paper is hard sheet by sheet, packages by square package, the size is cutted after production.Опширније -

What is Melamine Paper and How to Laminate Paper With a Machine

The process of melamine paper molding requires the following conditions. The process must be controlled to ensure quality. This article will introduce the process to make melamine-impregnated paper. Read on to know more. Decorative papers are often made of this material. They are extremely durable, heat-resistant, and water-resistant. They are easy to clean, making them a popular choice for high-demand furniture.Melamine paper is a type of direct laminate. It is typically produced with a high-pressure, short-cycle press line. The resin is applied to the paper layers and turns them into a solid plastic surface. When this paper is pressed onto a board surface, it does not need adhesive. Hot press machines are used to press the melamine paper onto the surface of the board. This material is commonly used for HPL and lamination flooring.Опширније -

Furniture Decor Papers Market Size, Share, Growth, and Industry Growth by Type

The global furniture décor paper market size was USD 2369.3 million in 2021 and is projected to touch USD 5023.49 million by 2032, exhibiting a CAGR of 7.1% during the forecast period. In the market study, our analysts have considered furniture décor paper players such as Felix Schoeller Group, Ahlstrom-Munksjö, Qifeng New Material, Koehler Paper, Malta-Décor, Surteco, Shandong Lunan New Materials, Impress Surfaces, KÄMMERER, Zhejiang Dilong New Material, SHENGLONG SPLENDECOR, Onyx Specialty Papers, PAPCEL, KJ Specialty Paper, and Pudumjee Paper Products, etc.Furniture décor paper is used to provide a high-end quality finish to wood materials. The papers either have a print or a normal design. It is used for flooring, furniture surfaces, and paneling. It is available in a wide range of colors and weights. The papers have color constancy, high porosity, light resistance, and wet strength.Опширније -

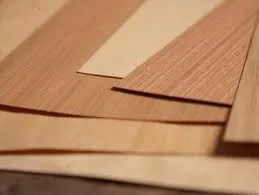

Demand Analysis Of My Country’s Decorative Paper Industry

Decorative paper is an indispensable raw material for many building materials products, such as low-voltage boards and high-voltage boards used in furniture and cabinets, as well as fire-resistant boards and floors. Decorative paper requires a smooth surface, good absorption and adaptability, a background color requires a uniform tone, and a color requires a bright color. Decorative paper is placed under the surface paper in the product structure, mainly to provide decorative patterns and cover to prevent the seepage of the underlying glue.Decorative paper has not been developed for a long time in our country, and it has only been more than 30 years. In the late 1960s, our country was using decorative paper as fireproof boards. These fireproof boards were manufactured by some large state-owned factories. Until the end of the 70's, research was started on paper to be directly veneered, but at that time the veneer was mainly used for medium density fiberboard and particleboard veneer.Опширније -

Small Knowledge Of Decorative Paper

Decorative paper is a kind of decorative paper, which is used for decoration and protection, and is mainly used for furniture, laminate flooring and Fire board and other fields. Decorative paper printing is a very specialized field with high technology and standards. The quality of decorative paper mainly depends on factors such as raw materials, printing technology, quality control and so on.Опширније -

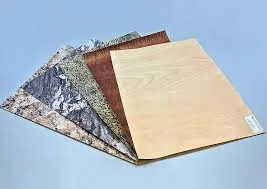

Factors affecting some quality properties of the decorative surface overlays

In this study, the influences of varnish and overlaying material types, structure of continuous pressed laminates (CPL) and resin mixture on the cigarette, scratch and abrasion resistances were investigated. Three-layered particleboard composites were overlaid with various decorative surface overlays (veneer, continuous pressed laminates, high-pressure laminates and finish foils). The results showed that the overlay and varnish types, and resin mixture used for the finish foil manufacturing were significantly found to be effective on the cigarette, scratch and abrasion resistances. While the lowest scratch and abrasion resistances were obtained from veneered boards, high-pressure laminates (HPL) had the highest values. Polyurethane based varnish showed higher resistances to the scratch and abrasion compared to cellulosic-based varnish. CPL structure was not found to be effective on these properties. The acrylic and urea mixture ratio used for the finish foil manufacturing was found to be effective on the abrasion and cigarette resistances. Increasing acrylic amount in the resin mixture statistically improved the quality properties of the finish foils. This study shows that end use applications of the overlaid panels are related to the overlay and varnish types, and resin mixture used for impregnating of the decor papers.Опширније -

Factors affecting the dimensional stability of decorative papers under moistening

A crucial problem for laminate producers is the dimensional instability of decorative papers during soaking in aqueous solutions, but the source of this dilemma is not completely understood yet. In this study, eight commercial decorative papers of similar fiber composition and sizing were analyzed for their structural, physical, and mechanical properties. These properties were examined for their correlations to the dimensional stability of papers when moistened, as assessed by the wet stretch dynamics. Structure-to-property relationships were evaluated by principal component analysis (PCA). Within the set of parameters examined, PCA revealed that fiber orientation and the content of fillers/pigments influenced the wet expansion of paper web and affected its margins and dimensions in longitudinal and transverse directions of the paper machine. These variables are discussed within the context of decorative paper engineering in order to produce high performance papers with regular wet expansion properties.Опширније -

Factors Affecting the Quality of Decorative Paper

Melamine-impregnated paper is used to decorate the surface of the paint-free board, providing colors and patterns. The overall demand is excellent. To have good quality, when producing melamine-impregnated paper, all factors need to be strictly controlled to meet its extensive requirements.Опширније -

Production process of melamine impregnated adhesive film paper

Melamine mdf board is also called paint-free board, it is a decorative board formed by hot pressing, which is to lay paper with different colors or textures on particleboard, moisture-proof board, MDF, plywood, blockboard or other solid wood boards.Опширније -

How to testing melamine impregnated paper veneer fiberboard and performance

There are many factors that can be considered when evaluating a product, including its performance, Intumescent, Flame retardant, water resistance, and hard surface texture. For example, a product may be described as flame retardant if it is flame retardant in the fire code. The fire code also requires a product to be waterproof and intumescent. However, these features are not always the same. This article will discuss the different methods for evaluating the properties of melamine-impregnated paper veneer fiberboard.Опширније -

Method of impregnating decorative paper with melamine resin

Decorative paper with a wear resistant decorative is made by limiting the flow of melamine resin through the decorative paper. A partially cured melamine resin impregnated overlay is placed over non impregnated decorative paper and cured at temperatures of about 230-310°F (110-155°C) and pressures of greater than about 300 psi (20 bar) and preferably about 750-1500 psi (51-102 bar) for causing melamine resin to flow from the overlay into the decorative paper and for substantially fully curing the melamine resin. Flow of the melamine resin is limited to about 10-20 and preferably about 12-17 percent by weight of the impregnated overlay. Flow of melamine resin in impregnated decorative paper is limited to about 1-3 and preferably about 1-2 percent by weight of the impregnated decorative paper.Опширније