Tala Fou

-

What is Duplex Board? Where is it used? BOARD PAPER

A Duplex board is a form of paperboard or cardboard that has a double-sided white or grey color. Because it is made of two layers, one side of it is made with a shiny finish to achieve excellent prints along with making it water-resistant.Faitau atili -

Types of Duplex Board Papers with their Applications BOARD PAPER

All Types of Duplex Board Papers with their Applications: Ever wondered about the world of Duplex Board Papers and how they discover their way into numerous applications?Faitau atili -

Why is duplex paper board used in food packaging? BOARD PAPER

DUPLEX BOARD is made from pure wood pulp with a bleached liner on one side. Used in food packaging.Used for this because it can be easily printed on and can be lined to protect it from drinks and foods. Lids for food liners .Used for this to help insulate the container and to help keep moisture in.Faitau atili -

APPLICATIONS OF DUPLEX BOARD PAPER Ceramic Bearing

A duplex board has 2 levels or layers. The treated duplex board features a shiny outer layer with one side for improved processability. A Duplex board is a less expensive version of a whiteboard with a similar top texture that provides a printed surface similar to that of the more expensive paper board.Faitau atili -

Duplex Board-Where is it used?

A Duplex board is a form of paperboard or cardboard that has a double-sided white or grey color. Because it is made of two layers, one side of it is made with a shiny finish to achieve excellent prints along with making it water-resistant. In simpler terms, a duplex board is an affordable variant of the premium whiteboard. It is commonly used in consumer packaging as well as in the industrial packaging sector. There are numerous suppliers of Duplex boards to purchase from, to cater to your business needs.Faitau atili -

Duplex Board-What is Duplex Board Commonly Used For?

Ever wonder what that thick, sturdy board is that shipping containers and product packaging are often made of? Chances are, it's a duplex board. You’ve probably handled a duplex board many times without even realizing it. This versatile material is used in a variety of industries for different applications.As an incredibly durable and cost-effective material, duplex boards are ideal for heavy-duty and high-volume uses. It’s the go-to material for applications where strength and affordability are equally important. Because it’s made from recycled materials, duplex boards are also an eco-friendly choice for companies looking to reduce their environmental impact.Faitau atili -

Duplex Board-wholesale contact paper to cover cabinet doors

Another variety of carton is also made from 80-100% recycled Pulp (Waste paper based) commonly called as Duplex board.Duplex board is a kind of paperboard or cardboard. It is called duplex board because it is made up of two layers, or plies. The exterior of the board is very often coated to make it more water-resistant and to give it a glossy sheen.Duplex board is tough, thin and able to take on a bright white appearance, unlike common corrugated cardboard. It is commonly used to create boxes for a variety of small goods. For example, it is often used in pharmaceutical packaging. It is also used to make garment boxes and cigarette packs, paper plates and cups, and in the food industry.Faitau atili -

Duplex Board-What is Duplex Board Paper Manufacturing Process

When producing duplex board paper, it is necessary to select matching raw materials according to the type, quality and specifications of duplex board paper required by the sales market. Raw Material SelectionHigh grade duplex board paper manufacturing, the surface layer uses bleached chemical wood pulp, and the core and bottom layers use sulphate wood pulp, mechanical wood pulp, high-quality waste paper, etc; and sub-level duplex board paper production, the surface layer uses bleached chemical wood pulp or fine white waste paper, the core and bottom layers use waste paper pulp.Faitau atili -

Duplex Board-Duplex Board Strength

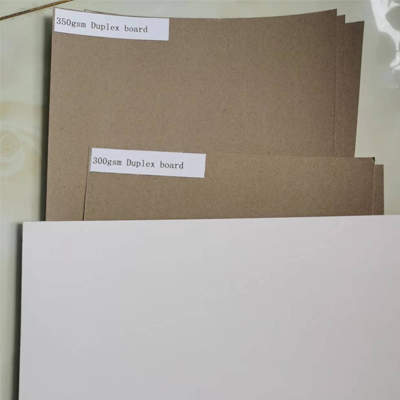

A Duplex board is paperboard made from two layers of paper. The top layer is made from bleached chemical pulp, and the bottom layer is made from recycled paper or virgin kraft paper. Duplex boards can be either white or brown, depending on the type of paper used for the top layer.There are two types of duplex boards: 1) solid bleached sulfate (SBS) and 2) folding boxboard (FBB). SBS is a high-quality duplex board often used for packaging food and other products that require a clean, white surface. FBB is a lower-quality duplex board often used for packaging products that do not require a clean, white surface.Faitau atili -

Duplex Board-Duplex Board Wholesale

A duplex board is a two-sided paperboard type with a glossy finish on one side and a matte finish on the other. It is made from a combination of recycled fiber and virgin fiber. It is a heavy-duty paperboard that is used to make packaging, boxes, and other products. It is flexible, strong, and durable enough to withstand the rigors of shipping and handling. Duplex board is used in many industries including food packing paper, beverage, and pharmaceutical. It is also used in good-quality paper for printing and publishing, as well as for book covers, stationery, and other paper products. A duplex board is an ideal choice for high-end packaging and printing projects.Faitau atili -

Duplex Board-Is the Duplex Board Right for You in 2023?

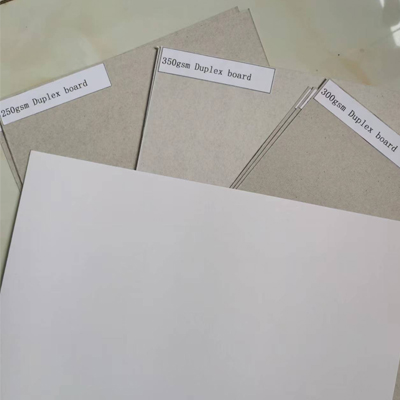

Duplex board is a type of paperboard that is made up of two layers of paper. The top layer, or face sheet, is usually made of a higher quality paper than the bottom layer, or liner. Duplex-board is available in a variety of thicknesses and weights, and it can be coated or uncoated.Duplex board is a popular choice for a variety of applications, including:Packaging: Duplex-board is commonly used for packaging food, beverages, cosmetics, and other products. It is also used for shipping containers and other industrial packaging.Printing: Duplex-board is a good choice for printing brochures, flyers, posters, and other marketing materials. It is also used for greeting cards, invitations, and other personal stationery.Faitau atili -

Duplex Board-Description of Duplex Board

The two layers of pulp in duplex board provide a smooth surface for printing, making it an ideal material for branding and marketing purposes. It can also be laminated with other materials such as plastic or aluminum foil to enhance its barrier properties.There are two types of duplex board: coated and uncoated. Coated duplex board has a layer of clay or other coating material applied to one or both sides to improve its printing properties and enhance its appearance. Uncoated duplex board, on the other hand, has a natural matte surface that is suitable for products that do not require a glossy finish.Faitau atili