Nov . 24, 2024 05:25 Back to list

oem grey back board

OEM Grey Back Board A Versatile Solution for Various Needs

In the rapidly advancing world of manufacturing and design, OEM (Original Equipment Manufacturer) solutions have become indispensable. Among these solutions, the grey back board has gained significant attention for its versatility and practicality across numerous applications. This article delves into the features, advantages, and diverse uses of OEM grey back boards, highlighting why they are an optimal choice for businesses seeking quality and efficiency.

What is OEM Grey Back Board?

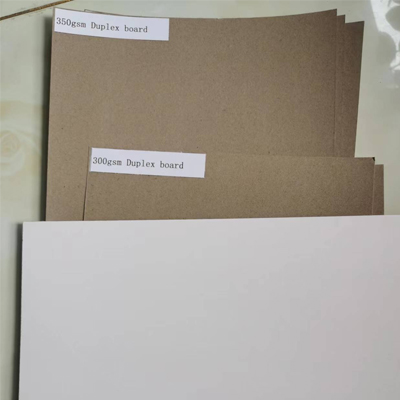

OEM grey back board is a type of paperboard that is widely used in packaging and product displays. It is characterized by its distinctive grey back and a smooth surface that is ideal for printing. This paperboard combines durability with an aesthetically pleasing appearance, making it an excellent option for a variety of industries, including retail, electronics, and food packaging.

Features and Specifications

One of the standout features of OEM grey back boards is their strength. They are typically manufactured to possess high tensile strength, allowing them to support substantial weight without bending or breaking. Additionally, the smooth surface of the grey back board enables high-quality printing, ensuring that brands can effectively communicate their messages to consumers.

The thickness of OEM grey back boards can vary, offering flexibility for different applications. Common thicknesses include 0.8mm, 1.0mm, and 1.5mm, which can be selected based on specific product needs. The grey back acts as a neutral backdrop, eliminating the risk of colors bleeding through, thus enhancing the final product’s visual appeal.

Advantages of OEM Grey Back Board

oem grey back board

1. Cost-Effectiveness Using grey back boards can significantly reduce packaging costs while maintaining structural integrity. Their durability means that fewer resources are needed for reinforcement, leading to cost savings.

2. Environmental Friendliness Many OEM grey back boards are made from recycled materials, making them an eco-friendly option for businesses aiming to reduce their carbon footprint.

3. Versatility These boards are not limited to one application. They can be used for product packaging, signage, displays, and even crafting, making them a flexible solution for various needs.

4. Customization Options Manufacturers often offer customization in terms of size, thickness, and printing. This flexibility allows businesses to create tailor-made solutions that meet their specific branding requirements.

Applications of OEM Grey Back Boards

The applications of OEM grey back boards are numerous. In retail environments, they are frequently used for shelf displays and point-of-purchase signage that need to catch customers' attention. In the electronics sector, they provide a sturdy base for packaging mobile devices and accessories, ensuring that products remain safe during transit. Furthermore, in the food industry, grey back boards can be employed for packaging items like takeout containers, adding an element of sophistication.

Conclusion

In conclusion, OEM grey back boards represent an innovative and practical solution for a broad range of industries. Their unique combination of durability, cost-effectiveness, and visual appeal makes them a preferred choice among manufacturers and businesses alike. As market demands continue to evolve, the versatility of OEM grey back boards ensures that they remain a valuable asset in the world of packaging and product presentation. Companies looking to enhance their offerings should certainly consider incorporating OEM grey back boards into their strategies for success.

-

Grey Contact Paper for Kitchen Cabinets Waterproof & Durable Solutions

NewsJun.01,2025

-

Removable Contact Paper for Furniture - Durable, Self-Adhesive Solutions

NewsJun.01,2025

-

Premium Cupboard Decoration with Paper Suppliers & Manufacturers

NewsMay.31,2025

-

Peel & Stick Dresser Paper Waterproof, Easy-Install Removable Decor

NewsMay.31,2025

-

Premium Uncoated Duplex Board Suppliers High-Strength & Eco-Friendly

NewsMay.31,2025

-

Stick Paper for Cabinets Durable & Water-Resistant Cabinet Films

NewsMay.31,2025