- Home

- coated duplex board grey back product

Feb . 14, 2025 11:30 Back to list

coated duplex board grey back product

Navigating the World of Coated Duplex Board Grey Back An In-Depth Exploration

In terms of authoritativeness, manufacturers of coated duplex board grey back often adhere to international quality standards. Certifications from established bodies such as ISO attest to the product’s reliability and quality management systems. Such certifications symbolize a commitment to maintaining high manufacturing standards, bolstering consumer confidence. Trustworthiness in the realm of coated duplex board grey back products also hinges on consistent supply chain management. For large-scale enterprises, a reliable supply chain ensures that there is no disruption in production, maintaining steady output levels and meeting market demands efficiently. Partners and stakeholders across the supply chain often foster long-term relationships, rooted in trust and mutual benefits, further enhancing product reliability. Beyond physical properties, engaging with coated duplex board grey back also extends into the domain of cost efficiency. Its production often entails lower costs compared to alternatives like virgin fiber boards, making it an economically viable option. The balance between cost, quality, and functionality is a persuasive argument for its adoption across various industries. Real-world experience from manufacturers using coated duplex board grey back highlights its robustness and adaptability. Many report reduced waste levels due to its higher yield, a testament to its efficient application in practical settings. Its adaptability is further evidenced by its widespread use in industries requiring customized solutions for diverse packaging needs. Exploring the coated duplex board grey back’s position within the packaging sector reveals its multifaceted utility. Its significance is projected to grow, driven by evolving market trends emphasizing sustainability and brand expression. Continued innovations will likely see enhancements in its properties, further solidifying its role as a staple material in packaging. Ultimately, the coated duplex board grey back stands as a testament to modern engineering and sustainable practices, fulfilling industry needs through expert craftsmanship and authoritative production methods. Its balance of quality, environmental consciousness, and reliability makes it an irreplaceable commodity in the ever-evolving landscape of packaging solutions.

In terms of authoritativeness, manufacturers of coated duplex board grey back often adhere to international quality standards. Certifications from established bodies such as ISO attest to the product’s reliability and quality management systems. Such certifications symbolize a commitment to maintaining high manufacturing standards, bolstering consumer confidence. Trustworthiness in the realm of coated duplex board grey back products also hinges on consistent supply chain management. For large-scale enterprises, a reliable supply chain ensures that there is no disruption in production, maintaining steady output levels and meeting market demands efficiently. Partners and stakeholders across the supply chain often foster long-term relationships, rooted in trust and mutual benefits, further enhancing product reliability. Beyond physical properties, engaging with coated duplex board grey back also extends into the domain of cost efficiency. Its production often entails lower costs compared to alternatives like virgin fiber boards, making it an economically viable option. The balance between cost, quality, and functionality is a persuasive argument for its adoption across various industries. Real-world experience from manufacturers using coated duplex board grey back highlights its robustness and adaptability. Many report reduced waste levels due to its higher yield, a testament to its efficient application in practical settings. Its adaptability is further evidenced by its widespread use in industries requiring customized solutions for diverse packaging needs. Exploring the coated duplex board grey back’s position within the packaging sector reveals its multifaceted utility. Its significance is projected to grow, driven by evolving market trends emphasizing sustainability and brand expression. Continued innovations will likely see enhancements in its properties, further solidifying its role as a staple material in packaging. Ultimately, the coated duplex board grey back stands as a testament to modern engineering and sustainable practices, fulfilling industry needs through expert craftsmanship and authoritative production methods. Its balance of quality, environmental consciousness, and reliability makes it an irreplaceable commodity in the ever-evolving landscape of packaging solutions.

Latest news

-

Premium Duplex Board Paper GPT-4 Turbo Enhanced for Packaging

NewsAug.03,2025

-

Premium Decor Base Paper | GPT-4-Turbo Enhanced | Durability

NewsAug.02,2025

-

Premium Decor Base Paper: High-Durability & Eco-Friendly Substrate

NewsAug.01,2025

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025

-

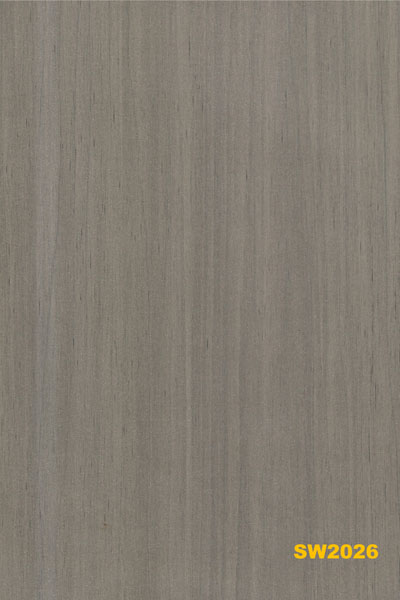

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025