- Home

- duplex paper manufacturing process supplier

Dec . 12, 2024 02:35 Back to list

duplex paper manufacturing process supplier

Understanding the Duplex Paper Manufacturing Process and Its Suppliers

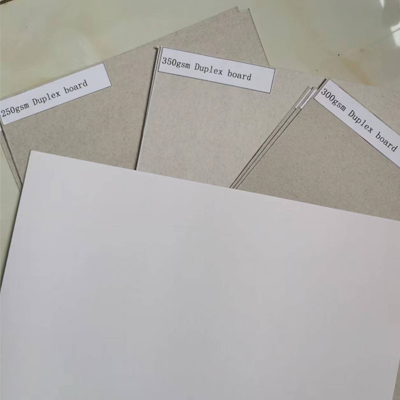

Duplex paper, known for its versatility and wide range of applications, has become an essential material in various industries including packaging, printing, and other paper-based products. The manufacturing process of duplex paper is intricate, involving multiple stages that require precision and high-quality raw materials. In this article, we will explore the duplex paper manufacturing process, its key suppliers, and the factors influencing their selection.

The Manufacturing Process of Duplex Paper

The production of duplex paper begins with the selection of raw materials. The primary components are recycled paper and wood pulp, which are carefully sourced to ensure sustainability and quality. The manufacturing process can be broken down into several key stages

1. Pulp Preparation In this first step, wood chips and recycled paper are converted into pulp. Chemical or mechanical methods are employed to break down the fibers, allowing the creation of a slurry that forms the paper. The pulp is washed and cleaned to remove impurities such as ink and other contaminants.

2. Sheet Formation The cleaned pulp is then diluted with water and fed onto a moving mesh screen. As the water drains away, the fibers begin to bond together, forming a wet sheet. This step is crucial as it determines the paper’s thickness, texture, and strength. The sheets are often pressed to remove excess water.

3. Drying The wet sheets are passed through a series of heated rollers to dry them completely. This step is necessary to achieve the desired moisture content, which is typically around 5-7%. Proper drying is essential for the strength and durability of the duplex paper.

4. Calendering Following drying, the paper sheets undergo calendering, where they are passed through a series of rollers under pressure. This process enhances the smoothness and thickness of the paper, giving it its characteristic duplex finish. The calendering stage may also involve coating the paper with a mixture of chemicals to improve its printability and appearance.

5. Cutting and Packaging Once dried and calendered, the paper is cut into standard sizes according to customer specifications. It is then packaged appropriately for shipping, ensuring that it remains in pristine condition upon delivery to manufacturers and end-users.

duplex paper manufacturing process supplier

Importance of Suppliers in the Duplex Paper Manufacturing Process

Selecting the right suppliers for duplex paper manufacturing is crucial for quality assurance and supply chain efficiency. The key considerations when choosing a supplier include

- Quality of Raw Materials Suppliers must provide high-grade wood pulp and recycled paper to ensure the finished product meets industry standards. Quality materials lead to stronger and more consistent duplex paper.

- Sustainability Practices As the demand for eco-friendly products rises, suppliers who prioritize sustainable sourcing and environmentally friendly practices tend to be favored. This includes certifications like FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative).

- Technological Advancements Modern duplex paper manufacturing relies heavily on technology. Suppliers who invest in cutting-edge equipment and processes can produce higher-quality paper more efficiently, which can be a significant competitive advantage.

- Reliability and Timeliness Consistent delivery and the ability to meet production deadlines are essential for manufacturers. Reliable suppliers not only provide materials on time but also support manufacturers in case of emergencies or unexpected disruptions in the supply chain.

- Price Competitiveness While quality is critical, cost efficiency is also important. Manufacturers must find a balance between high-quality materials and reasonable prices. Therefore, suppliers who offer competitive pricing can significantly influence a manufacturer’s operational budget.

Conclusion

In conclusion, the duplex paper manufacturing process is complex and requires a strategic approach to sourcing raw materials and working with suppliers. As industries continue to demand high-quality duplex paper, the relationship between manufacturers and their suppliers will play a pivotal role in ensuring that the final products meet customer expectations and environmental standards. By understanding the nuances of this process and the criteria for selecting suppliers, manufacturers can position themselves effectively in the competitive market of duplex paper products.

Latest news

-

Paper White Kitchen Cabinets Durable & Customizable Designs

NewsMay.24,2025

-

Premium Dressing Table Paper Trusted Suppliers & Global Exporters

NewsMay.24,2025

-

Premium Duplex Board Paper Manufacturers Competitive Pricing

NewsMay.24,2025

-

Durable & Easy-Install Contact Paper for Cabinet Doors Premium Designs

NewsMay.23,2025

-

Sticky Paper for Furniture Durable, Non-Slip Protective Covering

NewsMay.23,2025

-

Self-Adhesive Furniture Paper Durable & Customizable Solutions

NewsMay.23,2025