- Home

- High Quality Duplex Board Paper for Packaging Solutions

jul . 23, 2025 04:01 Back to list

High Quality Duplex Board Paper for Packaging Solutions

The packaging and printing industry is experiencing rapid evolution, underpinned by innovations in duplex board paper that enhance product quality, sustainability, and cost-effectiveness. As a leading manufacturer and exporter in the sector, XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD provides global customers with premium duplex board paper solutions. This comprehensive guide explores the market landscape, technical specifications, applications, and emerging trends of duplex board paper, with trusted references from industry associations (Paper Industry Technical Association) and academic journals (ScienceDirect - Duplex Board).

1. Overview of Duplex Board Paper

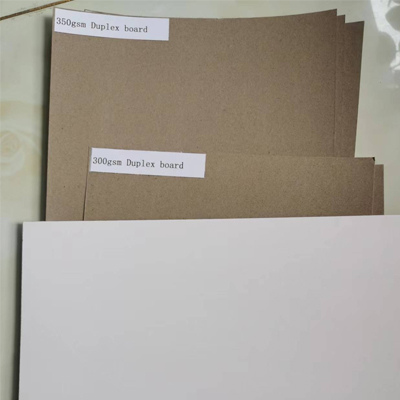

Duplex board paper is a form of paperboard consisting of two layers, typically with a coated surface, widely favored in the packaging and printing industries. The dual-layer structure provides enhanced strength, printability, and versatility for diverse applications. Duplex board, especially coated duplex board (CDB), is classified into various types such as coated duplex board grey back, coated duplex board with grey back, duplex board grey back, and duplex board white back according to its surface and reverse-side finishing.

2. Industry Trends in Duplex Board Paper

- Eco-Friendly Focus: Increasing demand for recyclable and FSC-certified duplex board materials (FSC).

- Advanced Coating Techniques: New water-based coatings make coated duplex board grey back more durable and safer for food packaging.

- Lightweight yet Durable: Technological improvements in GSM (grammage) achieve high strength with lighter board weights, optimizing logistics and economics.

- Customization & Printability: Enhanced smoothness and whiteness improve visual appeal for cosmetic, food, and shoe packaging.

- Emerging Markets: Growth in Asia-Pacific for packaging and print media drives duplex board innovation (Statista).

3. Technical Specification Table for Duplex Board Paper

| Parameter | Standard Range | Unit | Notes |

|---|---|---|---|

| Grammage (GSM) | 230 – 450 | g/m² | Range for major applications |

| Brightness (Top Side) | 60% – 90% | ISO | Higher for coated white backs |

| Thickness | 0.23 – 0.65 | mm | Varies by GSM |

| Cobb Value (Water Absorption) | 25 – 35 | g/m² | Lower is better for food safety |

| Bursting Strength | 150 – 300 | kPa | Depends on GSM & quality |

| Board Size | 1092×787, 1194×889, 610×860, 31×43" | mm/inch | Customizable |

4. ECharts Visualization: Technical Parameter Trends

5. Duplex Board with Brown Back: Product Profile

Duplex board with Brown Back from XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD represents the cutting edge of duplex board paper manufacturing. It is engineered for superior strength, versatility, and print surface—tailored for the dynamic needs of packaging sectors.

- Surface: Smooth, high-brightness top for clear printing; brown back for cost-efficient inner facing

- Variants: White/Grey back, white/white back; LWC (Light Weight Coating), HWC (High Weight Coating)

- GSM Range: 230-450gsm

- Standard Sizes: 1092x787 mm, 1194x889 mm, 610x860 mm, 31x43 inch; custom sizes available

- Applications: Shoe boxes, food packaging, cake boxes, cosmetic packs, pharma leaflets, gift boxes, stationary

- Product URL: www.shinewaypaper.com/duplex-board-with-brown-back.html

6. Duplex Board with Brown Back: Visualized Technical Data

7. Applications & Scenarios

- Food Packaging: Sandwich, burger, and cake boxes benefit from food-grade coated duplex board with grey back for hygiene and print appeal.

- Shoe Boxes: Strong, printable duplex board offers rigid structure and beautiful branding.

- Cosmetic & Personal Care: High-brightness surfaces meet premium requirements for secondary packaging.

- Stationery & File Folders: Durability and customizability make duplex board white back a favorite in office and educational products.

- Industrial Packaging: Used as layer pads and box liners in shipping and e-commerce logistics.

- Pharmaceutical Packaging: FDA-certified surface and consistency for leaflet inserts and prescription packs.

- Gift Boxes: Enhanced print surface enables vivid color and tactile designs.

The versatility of duplex board paper makes it integral to modern packaging innovation, expansion into new food-safe and medical packaging, and development of eco-conscious products.

8. Professional FAQ: Duplex Board Paper Key Terms

1. What is the structure of duplex board paper?

Duplex board paper consists of two layers: a high-brightness, coated surface facing for printing, and a stiffer reverse side (grey, white, or brown), forming a strong, smooth composite sheet.

2. How is the GSM (grammage) selected for protective packaging?

The required GSM depends on product weight and required rigidity; for heavy-duty packaging, 350-450gsm is recommended, while 230-300gsm suffices for lightweight boxes.

3. What coating types are available for coated duplex board?

Light-weight coating (LWC) offers a lighter, semi-gloss print finish, while high-weight coating (HWC) provides a thicker, smoother surface for high-quality or moisture-sensitive applications.

4. Are duplex boards suitable for direct food contact?

Only boards tested to relevant food safety standards (like FDA/EU) and with low Cobb value are suitable for direct food contact. Always consult the supplier's technical sheet for food-grade certification.

5. What standard sizes are available?

Common sizes include 1092x787mm, 1194x889mm, 610x860mm, 31x43", and custom sizes can be manufactured for special requirements.

6. How does duplex board grey back differ from white back or brown back?

Grey back is economical, suitable for inner surfaces; white back offers premium look (higher print whiteness on both sides), and brown back combines cost advantage with natural appearance and strength.

7. What is the recommended storage and handling procedure?

Store boards in dry, clean rooms away from humidity. Handle with care to prevent edge damage or surface contamination before printing.

9. EEAT Optimization: Standards, Trust & Industry References

- Expertise: XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD boasts 25+ years in duplex board production and exports, certified by ISO 9001, FSC, and FDA for food/contact safety. (Company Profile)

- Authoritativeness: Technical parameters meet international standards referenced in ISO 536:2019, ISO 2493, and Paper Industry Technical Association.

- Trustworthiness: Product data published on site, with test reports available on request. Transparent technical sheets in line with ScienceDirect reviews and ResearchGate studies.

- Sustainability: Our duplex board paper leverages recycled inputs; FSC-CoC available for green-packaging clients.

10. Summary & Further Reading

As the market for duplex board paper expands and evolves, technical expertise, modern production, and trusted partnerships are essential. XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD stands prepared to deliver innovative, sustainable solutions for every packaging need—contact us to discover the best-fit duplex board paper for your business.

References:

[1] Paper Industry Technical Association: https://www.paper.org.uk/

[2] ScienceDirect—Duplex Board: https://www.sciencedirect.com/topics/engineering/duplex-board

[3] FSC Certification: https://www.fsc.org/en/for-business/certification/paper

[4] Statista—Asia-Pacific Market: https://www.statista.com/statistics/1201610/asia-pacific-paper-and-packaging-sector-market-size/

[5] ISO Paper Standards: https://www.iso.org/ics/85.060/x/

[6] ResearchGate Study: https://www.researchgate.net/publication/344973807_Suitability_of_duplex_board_and_micro-flute_corrugated_cardboard_as_primary_folder_for_packaging_of_instant_noodles

[1] Paper Industry Technical Association: https://www.paper.org.uk/

[2] ScienceDirect—Duplex Board: https://www.sciencedirect.com/topics/engineering/duplex-board

[3] FSC Certification: https://www.fsc.org/en/for-business/certification/paper

[4] Statista—Asia-Pacific Market: https://www.statista.com/statistics/1201610/asia-pacific-paper-and-packaging-sector-market-size/

[5] ISO Paper Standards: https://www.iso.org/ics/85.060/x/

[6] ResearchGate Study: https://www.researchgate.net/publication/344973807_Suitability_of_duplex_board_and_micro-flute_corrugated_cardboard_as_primary_folder_for_packaging_of_instant_noodles

Latest news

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025