- Home

- Wholesale Production Process for Duplex Paper Manufacturing in the Paper Industry

Oct . 02, 2024 20:04 Back to list

Wholesale Production Process for Duplex Paper Manufacturing in the Paper Industry

The Wholesale Duplex Paper Manufacturing Process

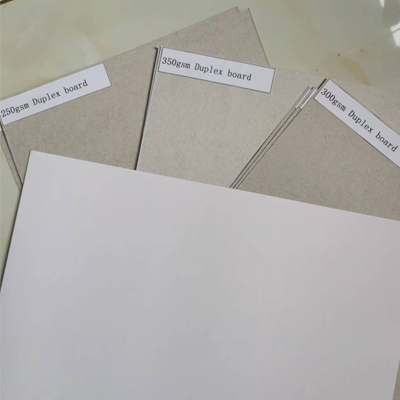

Duplex paper, a popular choice in packaging and printing industries, is renowned for its versatility and durability. The manufacturing of duplex paper involves a complex process that ensures high-quality output suited for various applications. Understanding this process can provide insight into how duplex paper is produced efficiently on a wholesale scale.

Raw Materials

The primary raw materials used in duplex paper manufacturing are recycled paper, wood pulp, and various additives. Recycled paper serves as a sustainable and cost-effective option, while wood pulp, which can be sourced from both sustainably managed forests and recycled fibers, adds strength to the final product. Additives, such as fillers and binders, are incorporated to enhance properties such as brightness, smoothness, and printability.

Pulp Preparation

The manufacturing process begins with pulp preparation. The raw materials are first sorted and cleaned to remove impurities. This step is crucial, as any contaminants can affect the quality of the paper. The cleaned raw materials are then fed into a pulping machine, where they undergo mechanical and chemical processes to break them down into a slurry of fibers. This pulp is subsequently bleached to achieve the desired whiteness and brightness levels for duplex paper.

Forming the Paper Sheet

Once the pulp is prepared, it is pumped onto a machine called the Fourdrinier machine, which is responsible for forming the paper sheet. The slurry is evenly spread on a moving wire mesh belt, allowing excess water to drain away. As the pulp travels along the belt, it forms a continuous sheet. The sheet continues to pass through several press rolls, which apply pressure to help remove more water and consolidate the fibers.

wholesale duplex paper manufacturing process

Drying Process

The newly formed sheet of paper then enters the drying section of the machine. Here, it is passed through heated rollers that further evaporate the remaining moisture, resulting in a dry sheet of paper. This drying process is critical, as it affects the final weight, thickness, and overall quality of the duplex paper.

Coating and Sizing

After drying, the paper may undergo a coating process to enhance its surface properties. Coating formulations that typically include clay or latex are applied to the surface of the duplex paper. This process improves brightness, provides a smoother surface for printing, and increases the weight of the paper. Sizing agents may also be applied to improve water resistance and reduce ink absorption, making the paper suitable for high-quality printing applications.

Cutting and Packaging

Once the duplex paper has been coated and sized, it moves to the cutting section, where it is cut into sheets or rolls of various sizes, depending on customer specifications. The final stage involves quality control inspections, where sheets are checked for consistency in thickness, color, and surface smoothness. After passing inspection, the duplex paper is packaged for wholesale distribution.

Conclusion

The wholesale duplex paper manufacturing process is an intricate blend of mechanical and chemical techniques aimed at producing a high-quality product. From raw material sourcing to the final packaging, every step is crucial in ensuring that the duplex paper meets the diverse needs of the market. As sustainability becomes increasingly important, many manufacturers are focusing on utilizing recycled materials, thereby contributing to environmental conservation while delivering quality paper products to consumers. This process not only supports the printing and packaging industries but also promotes a greener approach to paper production.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025