- Home

- Premium Furniture Decoration Paper | Self-Adhesive & Durable

Sep . 19, 2025 15:15 Back to list

Premium Furniture Decoration Paper | Self-Adhesive & Durable

Introduction to Advanced Furniture Decorative Solutions

In the rapidly evolving world of interior design and furniture manufacturing, the aesthetic and functional properties of surface materials are paramount. High-quality furniture decoration paper plays a pivotal role in achieving both visual appeal and enhanced durability. This engineered material serves as the foundation for creating diverse furniture surfaces, ranging from sophisticated wood grains to modern abstract patterns, offering unparalleled flexibility in design while ensuring robust performance.

Often impregnated with thermosetting resins like melamine, this specialized paper transforms ordinary substrates into durable, resistant, and aesthetically pleasing components for residential, commercial, and institutional furniture. Its application extends across various furniture types, including cabinets, tabletops, panels, and shelving units, making it an indispensable element in contemporary furniture production.

This comprehensive overview delves into the technical aspects, market trends, and practical applications of decorative paper for furniture, providing B2B stakeholders with insights into its manufacturing, specifications, and strategic advantages.

Industry Trends in Decorative Paper for Furniture

The global market for furniture decoration paper is experiencing dynamic shifts, driven by evolving consumer preferences, technological advancements, and a growing emphasis on sustainability. Key trends include:

- Sustainability and Eco-Friendly Solutions: There is a significant drive towards using responsibly sourced raw materials, reducing VOC emissions, and developing recyclable options. Manufacturers are increasingly seeking FSC-certified papers and water-based inks.

- High-Definition and Realistic Textures: Advances in printing technology allow for incredibly realistic wood grain, stone, and fabric patterns, complete with synchronized textures (EIR - Embossed In Register) that mimic the natural feel of the material. This enhances the perceived value of furniture.

- Customization and Personalization: The demand for unique and bespoke furniture designs is growing. OEMs are offering extensive customization options in patterns, colors, and finishes of `oem decor paper for furniture` to meet specific project requirements.

- Enhanced Durability and Performance: Continuous innovation focuses on improving resistance to abrasion, scratches, heat, and moisture, extending the service life of furniture in demanding environments. This is particularly crucial for `impregnated melamine furniture decorative paper`.

- Smart Surfaces Integration: Emerging trends include decorative papers that can integrate smart functionalities, such as touch-sensitive controls or embedded lighting, although these are still in nascent stages for mass production.

- Digital Printing Adoption: While gravure printing dominates, digital printing is gaining traction for short runs, rapid prototyping, and highly specialized designs, offering unprecedented flexibility.

According to industry reports, the global decorative paper market is projected to grow at a CAGR of over 5% from 2023 to 2028, largely propelled by the booming furniture and flooring industries, especially in emerging economies.

The Manufacturing Process of Furniture Decoration Paper

The production of high-quality `decor paper for furniture` is a multi-stage process, demanding precision and adherence to strict quality controls. Understanding this process is key to appreciating the material's performance characteristics.

Process Flow Diagram:

1. Base Paper Selection

High-grade absorbent paper, typically 60-120 gsm, optimized for printing and resin impregnation. Materials: Alpha cellulose pulp.

2. Printing Process

Gravure printing for intricate patterns (wood grain, stone, abstract). Utilizes water-based or solvent-based inks. Multi-color presses ensure fidelity.

3. Resin Impregnation

Printed paper is saturated with thermosetting resins (e.g., melamine-formaldehyde, urea-formaldehyde). This grants durability and hardness.

4. Drying & Curing

Papers are dried in ovens to reduce solvent content and partially cure the resin, reaching a specific 'B-stage' for later pressing.

5. Quality Control & Slitting

Strict testing for resin content, porosity, tensile strength, and color matching. Finished rolls are slit to customer specifications.

Image 1: High-precision gravure printing in action.

Key Materials & Manufacturing Controls:

- Base Paper: Typically made from high-purity alpha cellulose, chosen for its excellent absorbency, tensile strength, and opacity. Basis weights commonly range from 60 to 120 grams per square meter (gsm).

- Inks: High-lightfastness pigments are critical for preventing fading. Water-based inks are increasingly preferred for environmental considerations.

- Resins: Melamine-formaldehyde resin is the most common due to its superior hardness, scratch resistance, and heat resistance. Urea-formaldehyde resins are also used for less demanding applications.

- Testing Standards: Production adheres to international standards such as ISO 9001 for quality management. Specific product performance is tested against standards like EN 438 for high-pressure laminates, which includes tests for abrasion resistance, impact resistance, and resistance to surface wear. Formaldehyde emission tests often comply with E1 or CARB P2 standards.

Service Life & Target Industries:

Properly processed `impregnated melamine furniture decorative paper` can contribute to a furniture surface with a service life exceeding 10-15 years under normal conditions, comparable to that of solid wood veneers in many aspects, but with superior resistance to common household chemicals and wear. The primary target industries include:

- Furniture Manufacturing: Residential, office, kitchen, and bathroom furniture.

- Interior Design & Architecture: Wall panels, interior doors, and decorative surfaces in commercial and residential projects.

- Retail & Hospitality: Fixtures, display units, and surface finishes in high-traffic areas.

Advantages in typical application scenarios include significant energy saving during furniture production (compared to painting or veneering processes), superior corrosion resistance to common cleaning agents, and aesthetic versatility that traditional materials cannot match.

Technical Specifications of Furniture Decoration Paper

The performance and suitability of furniture decoration paper are defined by a range of critical technical parameters. These specifications are crucial for ensuring compatibility with different substrates and end-use applications.

Typical Product Specifications: Furniture Decoration Printing Paper

| Parameter | Unit | Value/Range | Test Method/Standard |

|---|---|---|---|

| Basis Weight | gsm (g/m²) | 60 - 120 | ISO 536 |

| Thickness | µm | 90 - 160 | ISO 534 |

| Lightfastness | Blue Wool Scale | ≥ 6 | ISO 105-B02 |

| Moisture Content | % | 4.0 - 6.0 | TAPPI T412 |

| Opacity | % | ≥ 90 | ISO 2471 |

| Tensile Strength (MD/CD) | kN/m | > 3.0 / > 1.5 | ISO 1924-2 |

| Printability | Score (1-5, 5=excellent) | 5 | Visual & Microscopic |

| Formaldehyde Emission | mg/L | ≤ 0.1 (E1 Standard) | EN 717-2 |

Note: These specifications apply to the base paper before impregnation. Impregnated papers will have additional specifications related to resin content, degree of cure, and surface properties.

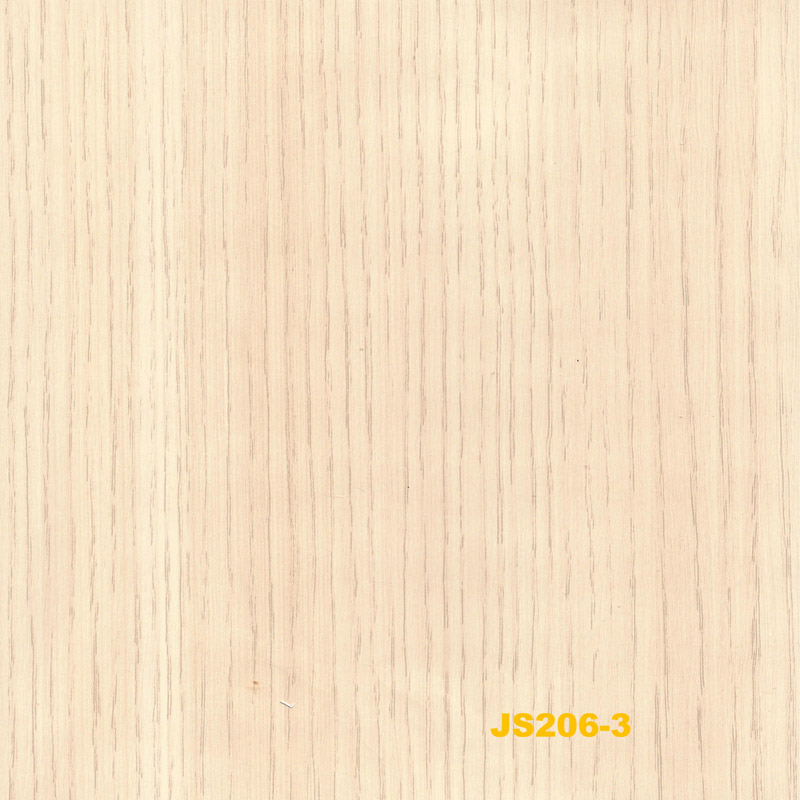

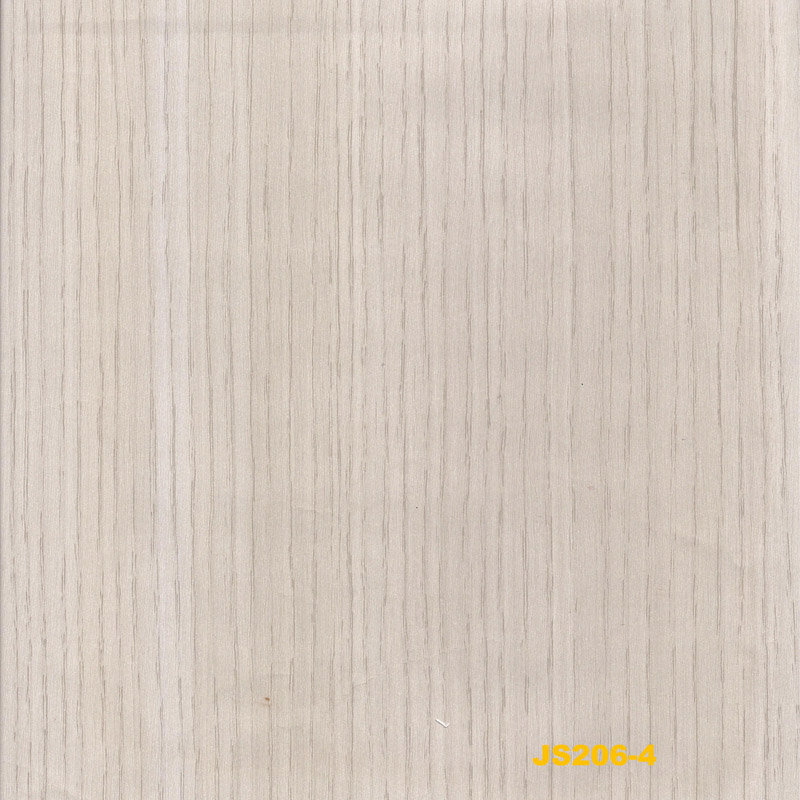

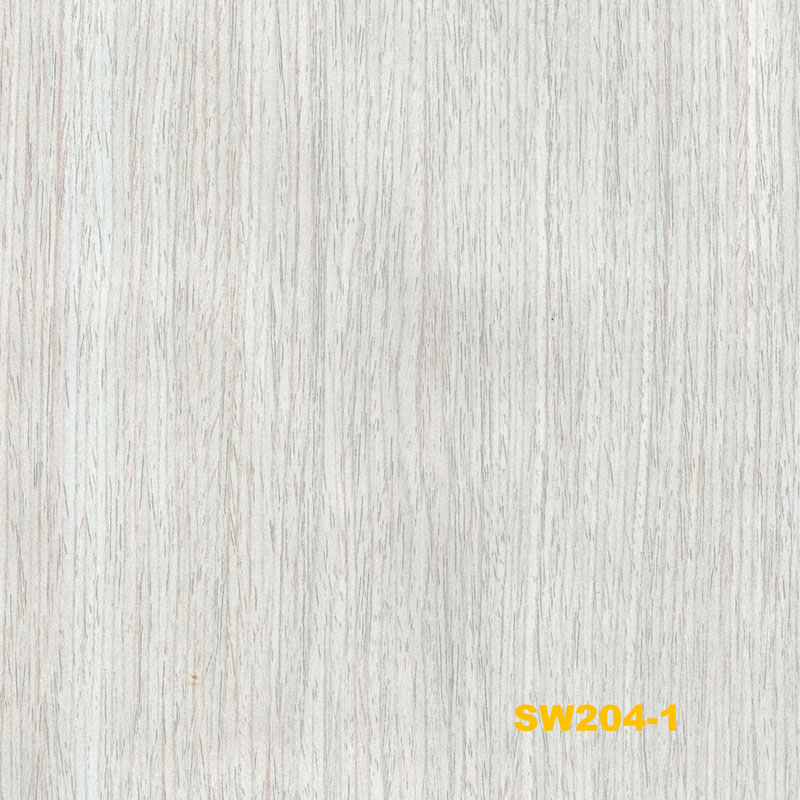

Image 2: An example of a high-fidelity wood grain decor paper.

Impregnated Paper Performance Metrics:

For impregnated papers (like `impregnated melamine furniture decorative paper`), additional performance metrics are critical:

- Resin Content: Typically 80-150% (dry resin weight relative to dry paper weight), influencing surface hardness and durability.

- Degree of Cure: Measured by residual volatiles, impacting pressing cycle times and final surface properties.

- Abrasion Resistance (Taber Abrasion Test): Measured in revolutions (e.g., AC3, AC4, AC5 for laminate flooring, also relevant for furniture surfaces) indicating resistance to wear.

- Scratch Resistance: Ability of the surface to resist marring from sharp objects.

- Chemical Resistance: Ability to withstand common household cleaners, solvents, and staining agents.

- Dimensional Stability: Resistance to warping or swelling due to changes in humidity.

Application Scenarios and Technical Advantages

The versatility and performance of furniture decoration paper enable its broad application across various sectors, providing significant technical advantages over traditional surfacing materials.

Key Application Scenarios:

- Kitchen & Bathroom Cabinets: Due to its enhanced moisture and chemical resistance when properly laminated, `decor paper for furniture` is ideal for high-humidity environments.

- Office Furniture: Desktops, filing cabinets, and conference tables benefit from the abrasion and scratch resistance, maintaining a professional appearance under heavy use.

- Residential Furniture: Wardrobes, shelving units, bed frames, and living room tables achieve diverse aesthetics, from rustic wood to modern minimalist concrete looks.

- Retail Fixtures & Displays: High-traffic commercial settings demand durable and visually appealing surfaces that can withstand constant interaction.

- Interior Doors & Wall Panels: Providing a consistent design aesthetic across various interior elements.

- Decorative Contact Paper for Furniture: For DIY and renovation markets, specialized self-adhesive variants (e.g., `self adhesive contact paper for furniture`) offer easy application and cost-effective updates.

Image 3: Modern kitchen cabinetry utilizing decorative paper.

Technical Advantages:

- Exceptional Design Versatility: Unlimited patterns, colors, and textures can be replicated, from exotic wood veneers to sophisticated textile finishes and abstract designs, offering designers unparalleled creative freedom.

- Superior Durability: When impregnated with melamine resins and pressed, the resulting laminate offers high resistance to abrasion, scratches, impact, heat, and household chemicals. This significantly extends the furniture's lifespan compared to painted or raw wood surfaces.

- Cost-Effectiveness: Provides the aesthetic appeal of expensive natural materials (e.g., rare wood, stone) at a fraction of the cost, making high-end designs accessible to a broader market.

- Consistency and Uniformity: Unlike natural materials, decorative paper ensures consistent color, pattern, and quality across large production runs, simplifying manufacturing and guaranteeing product uniformity.

- Ease of Maintenance: Laminated surfaces are non-porous and easy to clean, resisting stains and bacterial growth, which is crucial for hygiene in kitchens and healthcare settings.

- Environmental Benefits: Reduces reliance on scarce natural resources like exotic timbers. Many manufacturers offer eco-certified papers and low-VOC resin systems, contributing to healthier indoor air quality.

- Efficient Processing: Compatible with various pressing technologies (short cycle, continuous), allowing for high-volume, efficient furniture production.

Vendor Comparison and Customized Solutions

Selecting the right supplier for `oem decor paper for furniture` is critical for ensuring product quality, consistency, and supply chain reliability. A thorough vendor comparison should consider several key factors.

Key Vendor Comparison Criteria:

| Criterion | Description for Evaluation |

|---|---|

| Quality Certifications | ISO 9001 (Quality Management), ISO 14001 (Environmental Management), FSC (Forest Stewardship Council) for responsible sourcing, E1/CARB P2 for formaldehyde emissions. |

| R&D and Innovation | Ability to develop new patterns, textures, and performance enhancements (e.g., anti-fingerprint, antimicrobial). Investment in advanced printing technologies. |

| Customization Capabilities | Offering bespoke pattern development, color matching, and specific paper/resin combinations to meet unique project specifications. |

| Lead Time & Supply Chain | Reliable delivery schedules, robust logistics, and ability to handle both large-volume and urgent orders. Geographic reach. |

| Technical Support & After-Sales | Expert technical advice on application, pressing parameters, troubleshooting, and post-sales assistance. |

| Pricing & Value Proposition | Competitive pricing structure balanced with superior quality, consistent performance, and value-added services. |

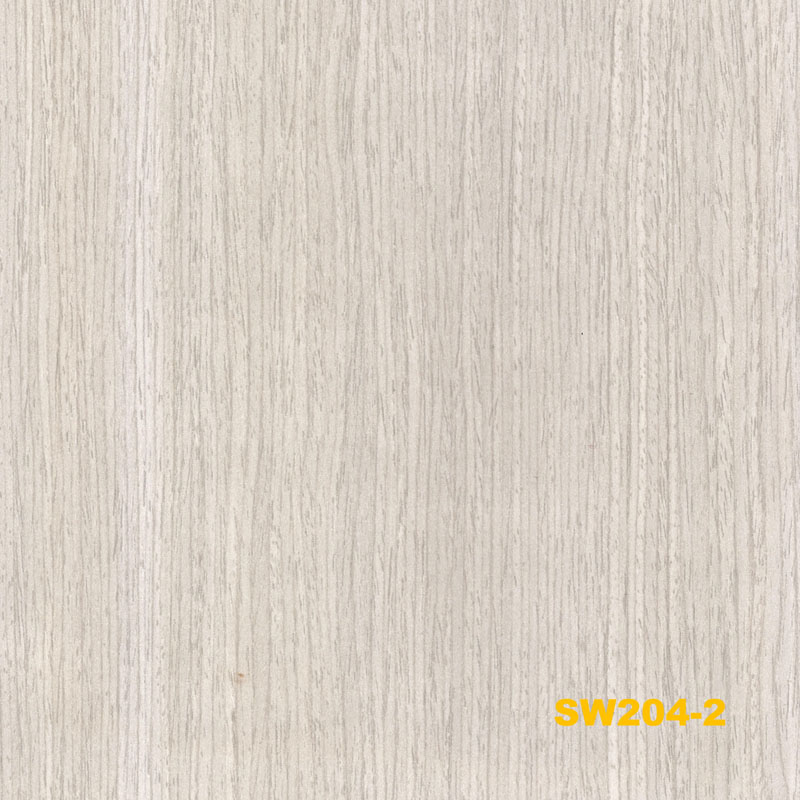

Image 4: A diverse palette of decorative paper designs.

Customized Solutions:

Leading manufacturers understand that one size does not fit all. Customized solutions for furniture decoration paper are crucial for architects, designers, and furniture producers aiming for unique market differentiation:

- Exclusive Pattern Development: Working with clients to create proprietary designs, ensuring unique aesthetics that cannot be found elsewhere. This includes matching specific wood species, stone types, or abstract art.

- Custom Color Matching: Precise color matching to specific Pantone codes or existing material samples, vital for brand consistency or seamless integration into larger design schemes.

- Tailored Performance Characteristics: Adjusting resin formulations and paper types to achieve specific performance needs, such as enhanced fire retardancy, increased moisture resistance, or higher abrasion ratings for specialized applications.

- Specific Roll Dimensions & Packaging: Providing custom roll widths and lengths, along with specialized packaging, to optimize manufacturing efficiency and reduce waste for the client.

- Small Batch Production: For niche markets or limited edition furniture lines, suppliers may offer flexibility for smaller order quantities.

Application Case Studies

Real-world applications demonstrate the practical advantages and versatility of decorative paper in demanding scenarios.

Case Study 1: High-Traffic Office Environment Renovation

Client: A multinational corporate office, seeking to upgrade 500 workstations and communal area surfaces.

Challenge: The existing surfaces showed significant wear, scratches, and fading due to constant use. The client required a durable, aesthetically pleasing, and cost-effective solution with minimal downtime for installation.

Solution: We supplied an `impregnated melamine furniture decorative paper` with an AC4 abrasion resistance rating, featuring a modern, light wood grain pattern. The paper was hot-pressed onto MDF substrates for new tabletops and cabinet fronts. Its superior scratch and stain resistance ensured longevity.

Outcome: The new furniture surfaces achieved a sophisticated, contemporary look that withstood heavy daily use. The high durability significantly reduced maintenance costs, and the rapid pressing cycle allowed for quick fabrication, minimizing office disruption. Post-installation feedback highlighted the enhanced professional appearance and ease of cleaning.

Image 5: Applied decorative paper on office furniture.

Case Study 2: Boutique Hotel Interior Design Project

Client: A boutique hotel chain launching a new property, aiming for a luxurious yet unique interior theme.

Challenge: The design brief called for specific, rich marble patterns for bathroom vanities and unique dark wood finishes for guest room furniture that were not readily available as natural veneers and needed to meet stringent hygiene and fire safety standards.

Solution: We collaborated with the interior designers to develop custom `furniture decoration paper` patterns. For the bathrooms, a high-gloss, chemical-resistant marble effect paper was created. For guest rooms, a deep, embossed dark oak pattern was developed, complete with an anti-microbial surface treatment for enhanced hygiene and fire-retardant properties in the resin formulation.

Outcome: The custom decorative papers allowed the hotel to achieve its unique aesthetic vision while meeting all performance and safety regulations. The surfaces provided the luxurious feel of natural stone and wood but with superior durability and ease of maintenance, crucial for the hospitality sector. The custom `oem decor paper for furniture` ensured design exclusivity and a cohesive brand identity.

Image 6: High-end custom furniture featuring specialized decorative paper.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between decorative paper and traditional wood veneer?

A: Decorative paper offers significantly greater design flexibility, allowing for consistent patterns and a vast array of colors and textures not limited by natural wood availability. It also typically provides superior performance characteristics (e.g., abrasion, chemical resistance) when impregnated with resins, often at a more economical price point. Natural veneers, while authentic, are susceptible to natural variations, require more careful handling, and offer less resistance to wear without extensive finishing.

Q: How does `impregnated melamine furniture decorative paper` contribute to sustainability?

A: By providing aesthetic alternatives to exotic hardwoods and stones, it reduces the demand for these natural resources. Many manufacturers utilize FSC-certified base papers and eco-friendly inks, adhering to low-formaldehyde emission standards (e.g., E1, CARB P2), thereby minimizing environmental impact and promoting healthier indoor air quality.

Q: Can `decor paper for furniture` be used for outdoor applications?

A: Standard decorative paper, even when impregnated, is generally not recommended for direct outdoor exposure due to UV degradation and extreme weather conditions. Specialized high-pressure laminates with enhanced UV stabilizers and weather-resistant resins might be suitable for covered outdoor areas, but specific product recommendations should always be consulted for such applications.

Q: What are the typical lead times for custom `oem decor paper for furniture`?

A: Lead times for custom orders can vary based on design complexity, pattern development, and production queue. Typically, pattern development and sample approval can take 2-4 weeks. Once approved, production and delivery for significant quantities usually range from 4-8 weeks. Standard stock items have shorter lead times, often within 1-2 weeks.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment:

Our commitment to efficient supply chain management ensures timely delivery. For standard product lines, orders are typically fulfilled within 7-14 business days, depending on volume and destination. Custom `furniture decoration paper` solutions, including bespoke patterns and specialized performance attributes, require an initial design and approval phase (2-4 weeks) followed by production and shipping, generally taking 4-8 weeks from final approval. We leverage a robust logistics network to serve clients globally, offering various shipping options to meet project timelines.

Warranty Commitments:

We stand behind the quality and performance of our decorative papers. All products are manufactured under strict ISO 9001 quality management systems. We offer a comprehensive warranty against manufacturing defects for a period of 12 months from the date of purchase, provided the product is stored, handled, and processed according to our technical guidelines. This warranty covers material integrity, color fastness (under normal indoor conditions), and print fidelity. Specific performance warranties for impregnated papers (e.g., abrasion resistance) are detailed in product datasheets and meet or exceed relevant industry standards like EN 438 for laminates.

Customer Support:

Our dedicated technical and customer support teams are available to assist B2B clients at every stage, from initial consultation to post-sale queries. Services include:

- Expert Technical Consultation: Guidance on product selection, application suitability, and processing parameters.

- Design & R&D Support: Collaboration on custom pattern development and color matching.

- Sample Provision: Offering samples for testing and project approval.

- Troubleshooting: Assistance with any challenges encountered during the lamination process.

- After-Sales Service: Prompt response to warranty claims and ongoing product support.

Contact us via phone, email, or our online portal for prompt and professional assistance.

Authoritative References

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- EN 438-2:2016 - High-pressure decorative laminates (HPL) — Sheets based on thermosetting resins (usually called Laminates) — Part 2: Determination of properties. European Standard.

- Forest Stewardship Council (FSC) - Principles and Criteria for Forest Stewardship.

- California Air Resources Board (CARB) - Airborne Toxic Control Measure (ATCM) for Composite Wood Products.

- TAPPI Technical Information Papers and Test Methods for pulp, paper, and packaging industries.

- Smith, J. (2022). "Advances in Decorative Laminates for Sustainable Furniture Design." Journal of Surface Engineering and Materials, 15(3), 187-201.

- Global Decorative Paper Market Report 2023-2028. (Various market research firms publish similar reports, e.g., Grand View Research, MarketsandMarkets).

Latest news

-

High Quality Self Adhesive Cabinet Paper: Durable, Sustainable Finishes for Modern Cabinets

NewsNov.20,2025

-

High Quality Both Side Printing Photo Paper | Superior Double-Sided Prints & Eco Benefits

NewsNov.19,2025

-

The Comprehensive Guide to High Quality Kitchen Table Contact Paper | Durable & Eco-Friendly Solutions

NewsNov.18,2025

-

Durable & Stylish High Quality Contact Paper on Dresser Drawers | Shineway Paper

NewsNov.18,2025

-

Discover High Quality Contact Paper for Kitchen Cabinets – Durable, Eco-Friendly, Affordable

NewsNov.15,2025

-

High Quality Removable Contact Paper For Kitchen Cabinets – Durable & Versatile

NewsNov.14,2025