Nov . 25, 2024 15:07 Back to list

oem uncoated duplex board

Understanding OEM Uncoated Duplex Board A Comprehensive Overview

In the realm of packaging and printing, the material used plays a pivotal role in the quality and presentation of the final product. One such material that has been gaining traction in various industries is OEM uncoated duplex board. This article will delve into the characteristics, applications, and benefits of this versatile material.

What is OEM Uncoated Duplex Board?

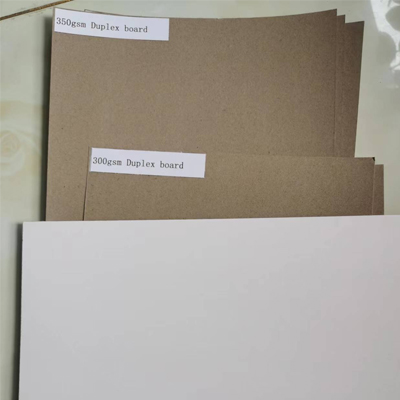

OEM, or Original Equipment Manufacturer, refers to companies that produce parts or equipment that may be marketed by another manufacturer. When we speak of OEM uncoated duplex board, we refer to a specific type of paperboard that is produced for other companies to use as their own branded product. Duplex board, in general, is a type of paperboard that is made from two layers of pulp, offering a strong and sturdy structure. The uncoated aspect indicates that the surface of the board has not been coated with a layer of finish, allowing it to maintain a more natural, raw feel.

Characteristics of OEM Uncoated Duplex Board

1. Strength and Durability One of the most prominent features of duplex board is its strength. The two-ply construction gives it enhanced durability, making it suitable for various applications, especially those requiring structural integrity.

2. Printable Surface Although uncoated, the surface of duplex board provides excellent print quality. It retains ink well, allowing for vibrant colors and intricate designs to be showcased.

3. Eco-Friendly Many OEM uncoated duplex boards are made from recycled materials, contributing to sustainability efforts within the packaging industry. As consumers become increasingly eco-conscious, using such materials can enhance brand image.

4. Cost-Effective Compared to coated boards, uncoated duplex board is often more affordable, making it an attractive option for businesses looking to cut costs without sacrificing quality.

Applications of OEM Uncoated Duplex Board

OEM uncoated duplex board finds usage in a variety of sectors

. Some typical applications includeoem uncoated duplex board

- Packaging It is widely used for manufacturing boxes, cartons, and packaging materials due to its robust nature. Industries such as food, electronics, and cosmetics rely on duplex board for packaging their products.

- Printing Printing companies prefer uncoated duplex board for creating brochures, flyers, and business cards, as it allows for good ink absorption and quality printing.

- Stationery From notebooks to art pads, the durability and printable nature of duplex board make it a popular choice for various stationery products.

- Craft Projects Hobbyists and artists also utilize this material for crafting projects, given its flexibility and ease of use.

Benefits of Using OEM Uncoated Duplex Board

1. Versatility The wide array of applications for duplex board means it can cater to diverse business needs. Whether for packaging or printing, this material meets various requirements.

2. Customization Many OEM manufacturers offer customization options, allowing businesses to choose specific sizes, colors, and finishes that align with their branding.

3. Easy to Handle The lightweight nature of the board combined with its strength makes it easy to handle during production and assembly.

4. Enhanced Brand Image Utilizing quality packaging is crucial in today’s market. By choosing OEM uncoated duplex board, businesses can convey a commitment to quality and sustainability to their customers.

Conclusion

In conclusion, OEM uncoated duplex board is a remarkable material that stands out in the manufacturing and printing sectors. Its combination of strength, printability, and eco-friendliness makes it a preferred choice for many businesses. As industries continue to innovate and shift towards more sustainable practices, the demand for versatile packaging materials like OEM uncoated duplex board is likely to grow, driving further advancements and applications in the future.

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025