- Home

- High-Quality Uncoated Duplex Board for OEM Applications and Printing Solutions

Nov . 16, 2024 16:53 Back to list

High-Quality Uncoated Duplex Board for OEM Applications and Printing Solutions

Understanding OEM Uncoated Duplex Board A Comprehensive Overview

In the world of packaging and printing, OEM uncoated duplex board stands out as a versatile and essential material. This type of board caters primarily to the needs of original equipment manufacturers (OEMs) and is widely utilized in producing high-quality packaging solutions. With its unique attributes and advantages, uncoated duplex board has gained popularity among businesses seeking effective and sustainable packaging options.

What is Duplex Board?

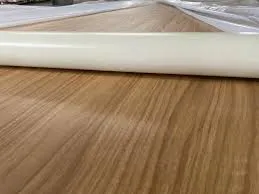

Duplex board is a type of paperboard composed of two layers. The outer layer provides a smooth surface, while the inner layer offers strength and durability. When referring to “uncoated” duplex board, it indicates that the surface has not been treated with any coatings or finishes, giving it a natural look and feel. This characteristic makes uncoated duplex board an excellent choice for various applications in the printing and packaging industry, as it allows for excellent ink adhesion.

Properties of OEM Uncoated Duplex Board

1. Eco-Friendly One of the most significant advantages of uncoated duplex board is its environmentally friendly nature. Made from recyclable materials, it aligns with the growing demand for sustainable packaging solutions. Businesses looking to reduce their carbon footprint find OEM uncoated duplex board an attractive option.

2. Print Quality Despite being uncoated, this type of board offers excellent print quality. Its natural surface allows inks to stand out vibrantly, making it ideal for high-quality graphics and designs. This feature is particularly beneficial for packaging that requires eye-catching visuals to attract consumer attention.

oem uncoated duplex board

3. Durability The robust construction of duplex board ensures that it can withstand the rigors of the supply chain. It is resistant to tearing, bending, and other forms of damage, making it a suitable choice for shipping and storing products. OEMs can rely on this material to protect their products while in transit.

4. Cost-Effectiveness In comparison to coated boards, OEM uncoated duplex board is often more affordable. This cost-effectiveness allows manufacturers to save on production costs, making it an attractive option for businesses aiming to maintain their profit margins without compromising on quality.

Applications of OEM Uncoated Duplex Board

The versatility of uncoated duplex board lends itself to various applications. It is widely used in producing boxes, cartons, and displays, and is commonly employed in the food and beverage industry for packaging items such as cereals, snacks, and takeout food. Additionally, it is favored for creating promotional materials, including brochures and flyers, owing to its exceptional printability.

Conclusion

In summary, OEM uncoated duplex board is a key player in the packaging and printing sectors. Its combined properties of sustainability, print quality, durability, and cost-effectiveness make it a favored choice for companies looking to create impactful packaging solutions. As businesses continue to prioritize eco-friendly practices, the demand for OEM uncoated duplex board is expected to rise, solidifying its position as a vital material in the industry. Embracing this versatile board can help companies not only enhance their products' appeal but also contribute to a more sustainable future.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025