- Home

- OEM grey back duplex board for various printing applications and packaging solutions

Nov . 07, 2024 13:28 Back to list

OEM grey back duplex board for various printing applications and packaging solutions

Exploring OEM Duplex Boards with Grey Back A Comprehensive Overview

In the realm of packaging and printing, the choice of materials plays a crucial role in determining the quality, durability, and aesthetic appeal of the finished products. One such material that has gained significant popularity in recent years is the OEM duplex board with a grey back. This article delves into the characteristics, advantages, applications, and manufacturing processes of this versatile board.

What is OEM Duplex Board?

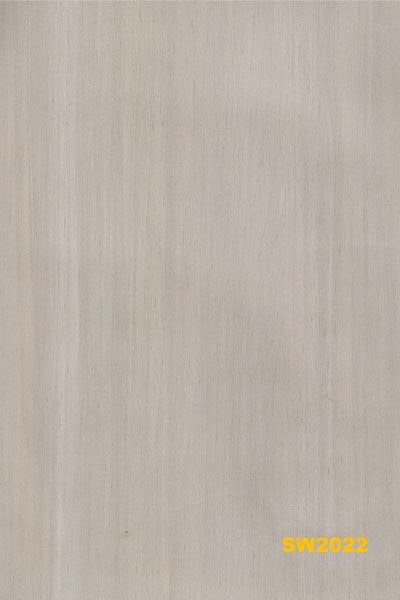

OEM stands for Original Equipment Manufacturer, and in this context, it refers to the use of duplex boards produced specifically for various clients, tailored to meet their specific needs. Duplex boards are made from two layers of paper, combined together to create a sturdy yet lightweight material. The term duplex indicates that the board is manufactured using a material that consists of two sides, typically with one side being white and smooth, while the other side is grey. The grey back offers a significant advantage in terms of opacity and print quality.

Characteristics of Duplex Board with Grey Back

1. Weight and Thickness Duplex boards come in various weights, typically ranging from 200 to 400 gsm. The thickness can vary according to specific product requirements, ensuring versatility for different applications.

2. Smooth Surface The white side of the duplex board provides an excellent surface for printing, allowing for vibrant colors and sharp images. This smoothness is essential for high-quality print outputs.

3. Environmental Impact Many manufacturers produce duplex boards using recycled materials, making them a more sustainable choice in comparison to other substrates. This aspect appeals to environmentally conscious businesses looking to reduce their ecological footprint.

4. Cost-Effectiveness Duplex boards are known for their affordability, providing an excellent balance between quality and cost. This makes them an attractive option for businesses, especially those focused on maximizing their return on investment.

Advantages of Using OEM Duplex Board with Grey Back

1. Versatile Applications OEM duplex boards are highly versatile and can be used in a wide range of applications, including packaging, printing, and crafting. Their strong structure makes them ideal for making boxes, displays, and marketing materials.

oem duplex board with grey back

2. High Opacity The grey back of the duplex board enhances opacity, which is crucial for packaging that requires a degree of light blocking. This feature ensures that products are well-protected and maintains their integrity during storage and transport.

3. Enhanced Print Quality The smooth white surface of the duplex board provides an ideal canvas for printing, resulting in vibrant graphics and text. This is particularly important for brands aiming to capture consumer attention through visually appealing packaging.

4. Customizable OEM duplex boards can be produced to meet specific client requirements, including custom sizes, weights, and finishes. This flexibility allows businesses to create unique packaging solutions that stand out in the marketplace.

Applications of OEM Duplex Board

The use of OEM duplex boards with grey back spans various industries. Here are some notable applications

1. Packaging Duplex boards are widely utilized in the packaging industry for making boxes, cartons, and protective packaging solutions. They are particularly favored for food packaging, electronic goods, and retail items due to their strength and durability.

2. Print Media The printing industry uses duplex boards for producing brochures, flyers, and other marketing materials, benefiting from the board's high print quality and sharp images.

3. Crafting Many artisans and crafters use duplex boards for creating greeting cards, scrapbooking materials, and other handmade items, attracted by the board's easy-to-cut nature and smooth surface.

4. Point of Purchase Displays Retailers often employ duplex boards for making eye-catching point-of-purchase displays and signage, leveraging the board's structural integrity and printability to draw in customers.

Conclusion

The OEM duplex board with grey back is an indispensable material in today's packaging and printing landscape. Its unique combination of durability, print quality, and environmental friendliness makes it an ideal choice for a myriad of applications. As businesses continue to seek innovative and cost-effective packaging solutions, duplex boards will undoubtedly retain their relevance for years to come. Whether you're a manufacturer, printer, or crafter, investing in quality duplex boards can enhance your product offerings and contribute to your overall success in the competitive market.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025