- Home

- Looking for Furniture Decoration Paper with OEM Quality?

Oct . 01, 2025 11:30 Back to list

Looking for Furniture Decoration Paper with OEM Quality?

Furniture Decoration Printing Paper: field notes from the factory floor

If you’ve ever run your hand across a wardrobe panel and thought “that oak looks real,” there’s a good chance you were meeting furniture decoration paper at its best. I’ve walked a few lines in Xingtai and Suqian, and to be honest, the difference between good and great often hides in the print cylinder, the base paper, and the curing profile.

What’s trending now

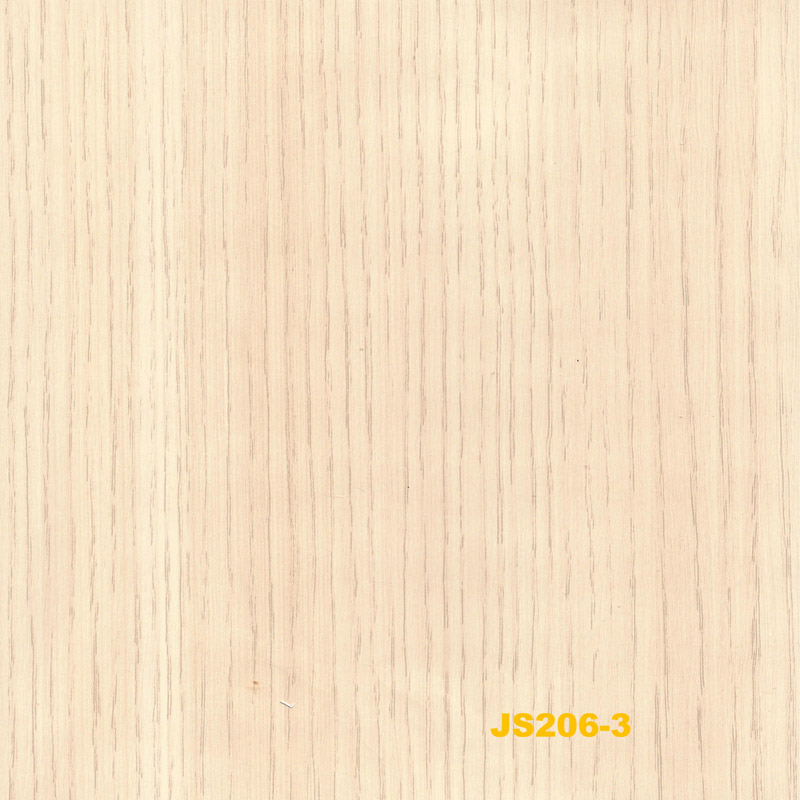

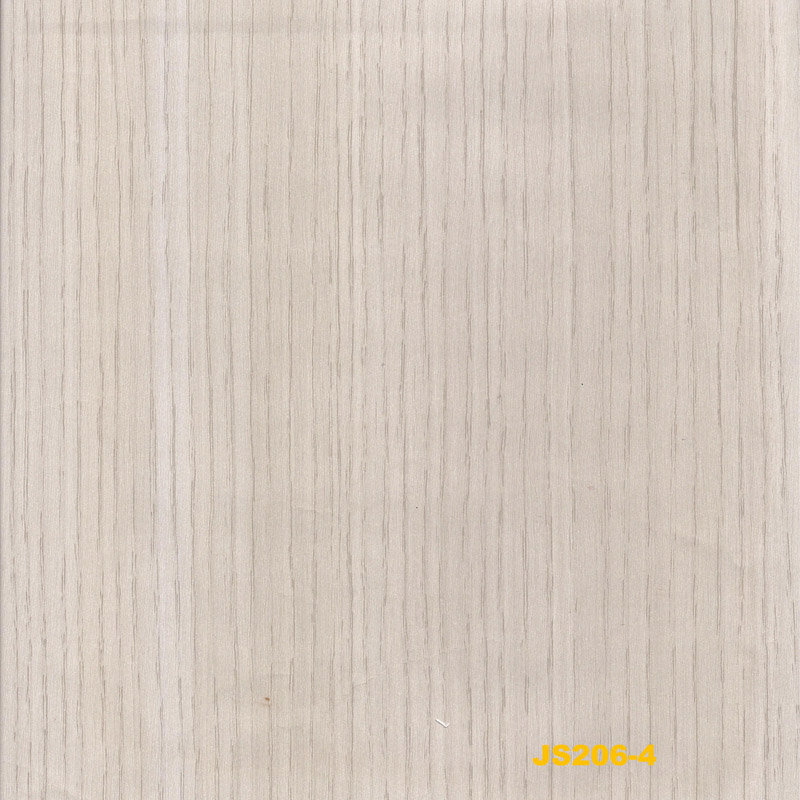

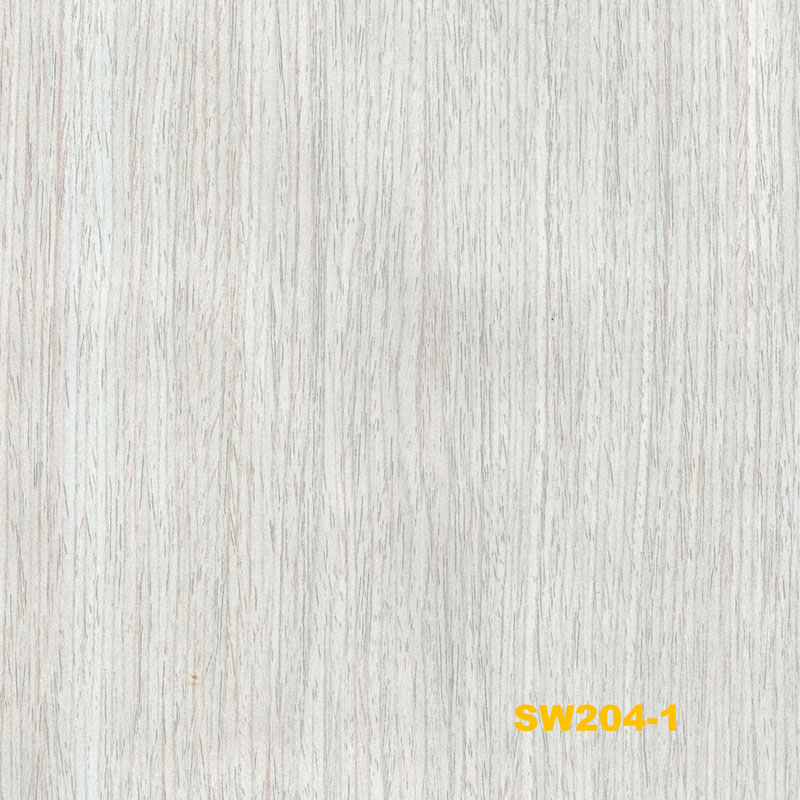

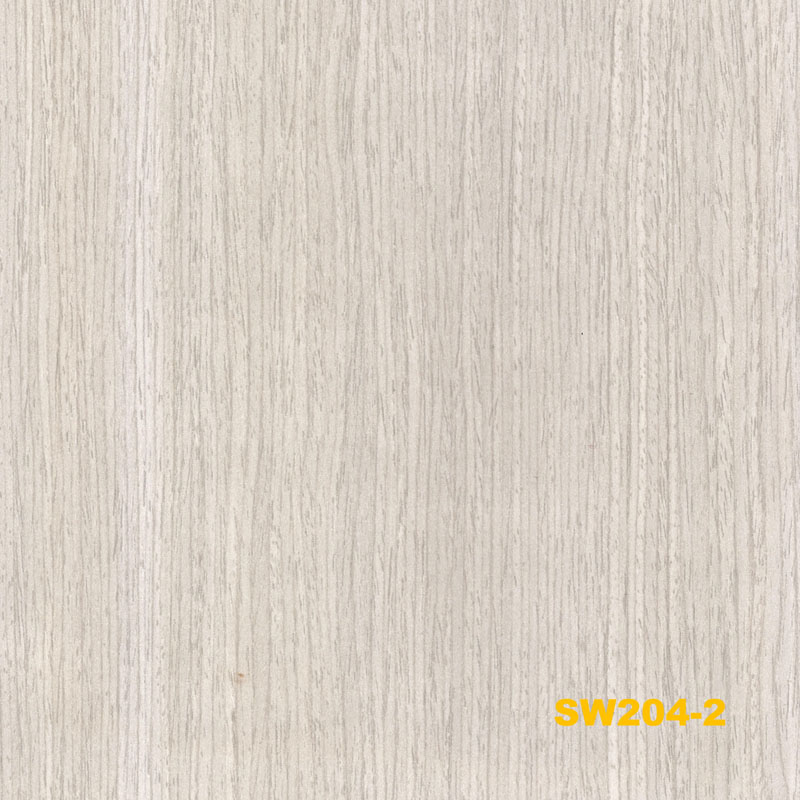

Three industry shifts keep popping up in my notes: ultra-matte finishes (less glare in retail lighting), upgraded lightfast inks (sunny apartments are unforgiving), and faster turnaround on custom grains. Many customers say they want “veneer realism” without veneer waste. Surprisingly, warm walnut and quiet ash are back, while concrete and textile prints hold steady in office projects.

Process flow (how it’s really made)

- Materials: decor base paper (≈70–85 g/m² cellulose), gravure inks (low-VOC, REACH-ready), optional melamine or urea-formaldehyde resin for impregnation.

- Methods: high-linecount gravure printing → color control (∆E ≈ ≤2.0 target) → moisture balance → optional resin impregnation → cutting/rewinding.

- Testing: rub resistance (ISO 105-X12), lightfastness (ISO 105-B02), scratch (GB/T 4893.9), odor/VOC checks; post-lamination Taber abrasion on finished board for real-world use.

- Service life: indoors ≈ 8–10 years in normal traffic; kitchens may see 5–8 depending on cleaning chemicals.

- Industries: residential furniture, closets, office desks, door skins, RV interiors, shopfitting.

Product specs snapshot

| Product Name | Furniture Decoration Printing Paper |

| Origin | Xingtai City, Hebei Province, China |

| Base weight | ≈70–85 g/m² (custom on request) |

| Print method | Gravure, 120–180 lpi; color ΔE ≤2.0 (lab conditions) |

| Roll width/length | 770–1260 mm / 2000–4000 m (≈, real-world may vary) |

| Post-lamination abrasion | LPL board: ≈300–600 revs (Taber CS-10, 500 g) |

| Cert alignment | REACH, RoHS inks; supports EN 14322 boards |

Why use furniture decoration paper over veneer? Consistency, lower scrap, smart cost per square meter, and easier color repeat across sites. After lamination, you get solid scratch resistance and stable edges for CNC work. Actually, it’s the predictable part of a sometimes unpredictable supply chain.

Vendor landscape (quick view)

| Vendor | MOQ | Custom lead time | Certs | Typical price/m² | Notes |

|---|---|---|---|---|---|

| Shineway Paper (Xingtai) | ≈3,000 m per design | 10–15 days after cylinder | REACH, RoHS inks | $0.35–$0.60 | Strong color repeat; fast reprint |

| Regional Mill A | ≈5,000 m | 15–25 days | REACH | $0.40–$0.70 | Broader pattern book |

| OEM Trader B | Low, but variable | 20–30 days | Declared | $0.38–$0.65 | Flexible sourcing; QC depends |

Customization, use-cases, and a quick case

- Design: oak, walnut, ash, marble, textile; Pantone matching within ΔE ≈2.0.

- Widths: 770–1260 mm; cylinders cut for your press width; repeat lengths tuned to panel sizing.

- Applications: MDF/particleboard wardrobes, kitchen fronts, office partitions, hotel casegoods.

Case study (informal): a South China office fit-out switched to furniture decoration paper with ultra-matte walnut; they reported fewer panel rejects and tighter seam alignment. Delivery shaved a week off the schedule—small win, big sigh of relief.

Quality, tests, and real data

- Lightfastness: ISO 105-B02 grade 6 target (sunlit rooms still need blinds—reality check).

- Scratch: ≥3.5 N on finished melamine-faced board (GB/T 4893.9).

- Color: print line ΔE ≤2.0; batch-to-batch ≤2.5 in controlled storage.

- Compliance: REACH and RoHS-compatible inks; supports EN 14322 board performance; TSCA/CARB depends on the substrate you laminate to.

Bottom line: if you want stable supply and consistent panels, start with reliable furniture decoration paper, then lock in your lamination recipe. It seems simple; it isn’t—but it’s doable.

References

- EN 14322:2017 — Wood-based panels, melamine faced boards, requirements.

- GB/T 4893.9-2013 — Furniture tests: surface scratch resistance.

- ISO 105-B02:2014 — Lightfastness tests using artificial light.

- REACH Regulation (EC) No 1907/2006 — Chemical safety framework.

- EPA TSCA Title VI / CARB Phase 2 — Formaldehyde limits for composite wood (applies to substrates).

Latest news

-

Discover High Quality Self Adhesive Paper for Cabinets – Durable, Sustainable, Stylish

NewsNov.24,2025

-

Premium High Quality Blue Contact Paper for Furniture | Durable Surface Solutions

NewsNov.23,2025

-

What Drives High Quality Duplex Paper Price? Key Factors and Global Insights

NewsNov.22,2025

-

High Quality Decorative Contact Paper for Cabinets | Durable & Stylish Solutions

NewsNov.22,2025

-

High Quality Stick Paper for Cabinets: Durable, Sustainable, and Stylish Surface Solutions

NewsNov.21,2025

-

High Quality Self Adhesive Cabinet Paper: Durable, Sustainable Finishes for Modern Cabinets

NewsNov.20,2025