- Home

- High-Quality Duplex Board: Coated, Grey Back & Versatile

Sep . 19, 2025 18:20 Back to list

High-Quality Duplex Board: Coated, Grey Back & Versatile

Understanding Duplex Board: A Foundation for Modern Packaging and Printing

The selection of appropriate materials is paramount in today's demanding industrial and commercial landscape, particularly within the packaging and printing sectors. Among the most versatile and widely utilized materials is the duplex board, a composite paperboard engineered for superior performance. This material, often referred to as duplex board paper, is characterized by its multi-layered structure, typically comprising a bleached, coated surface for optimal printability and a grey or unbleached reverse side for structural integrity and cost efficiency. Its balanced properties make it an indispensable asset for manufacturers seeking both aesthetic appeal and robust protection for their products.

Our discussion will delve into the intricate details of duplex board, from its advanced manufacturing processes and technical specifications to its diverse application scenarios, which include critical areas such as duplex board food packaging. We will also explore the technical advantages that position it as a preferred choice, offer insights into vendor comparison, and highlight customization capabilities, supported by tangible application case studies and adherence to stringent industry standards like ISO and FDA, affirming its authoritative standing in the market.

The Advanced Manufacturing Process of Duplex Board

The production of duplex board is a sophisticated process that integrates multiple stages, each meticulously controlled to ensure the final product meets exacting quality standards. The general process flow emphasizes material purity, structural integrity, and surface finish, crucial for applications ranging from consumer goods packaging to intricate printing projects.

Process Flow Overview:

- Pulp Preparation: This initial phase involves the mechanical and chemical pulping of various fibers. For the bright top layer, virgin pulp (bleached chemical pulp from wood like spruce or pine) is typically used to achieve high whiteness and smooth surface. For the core and back layers, recycled paper stock, often mixed with some virgin fibers for strength, is processed. These materials are meticulously cleaned, screened, and refined to create a homogeneous slurry, ensuring consistent fiber distribution.

- Layer Formation (Multi-Fourdrinier Machine): Unlike single-layer paper, duplex board is formed on multi-fourdrinier machines. Separate headboxes simultaneously lay down distinct layers of pulp onto moving wire meshes. The top layer, destined for printing, receives the high-quality bleached pulp, while subsequent layers, including the bulk core and the grey back (often made from recycled fibers, forming a duplex board with grey back), are formed from lower-grade or recycled pulp. This layering is critical for achieving the dual characteristics of the board.

- Pressing: Once the layers are formed, the wet web of paperboard passes through a series of press rolls. These rolls mechanically remove a significant portion of the water, compacting the fibers and increasing the sheet's density and strength. This stage is crucial for reducing drying energy consumption.

- Drying: The pressed board then enters a sophisticated drying section, where it passes over numerous steam-heated cylinders. Controlled temperature and humidity are vital to gradually remove residual moisture, preventing warping and ensuring dimensional stability. Modern dryers often employ advanced energy recovery systems, aligning with sustainable manufacturing practices and contributing to energy saving.

- Surface Coating: After initial drying, the top surface of the duplex board receives one or more layers of coating. This coating, typically a blend of pigments (e.g., kaolin, calcium carbonate), binders, and additives, is applied via blade or rod coater. The coating enhances brightness, smoothness, ink absorbency, and overall print fidelity, making it ideal for applications requiring high-resolution graphics, such as both side printing photo paper applications or premium packaging. This results in a coated duplex board grey back.

- Calendering: The coated board then goes through calender stacks, which are polished steel rolls. Calendering smooths and densifies the surface further, improving gloss, thickness consistency, and printability. For certain finishes, supercalendering can impart an even higher gloss.

- Slitting and Winding: Finally, the finished duplex board is wound onto large master rolls, which are then precisely slit into narrower rolls or cut into sheets according to customer specifications. This stage requires high precision to minimize waste and ensure uniform dimensions.

Throughout this process, rigorous testing standards, including ISO 9001 for quality management and ISO 14001 for environmental management, are strictly adhered to. Product materials are selected for their sustainability and performance, often including recycled content. The target industries benefiting from this manufacturing precision include general packaging, pharmaceuticals, cosmetics, electronics, and especially duplex board food packaging, where hygiene and barrier properties are critical. The advantages extend to superior print quality, enhanced structural rigidity, and optimal cost-effectiveness due to the strategic use of materials, providing a longer service life for packaged goods.

Technical Specifications and Industry Data for Duplex Board

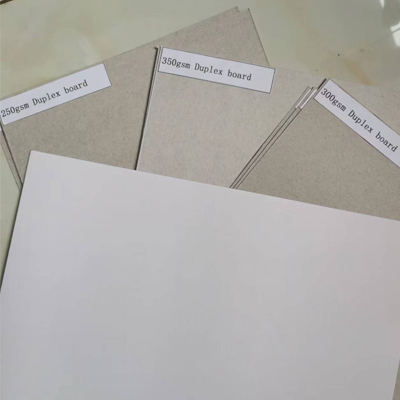

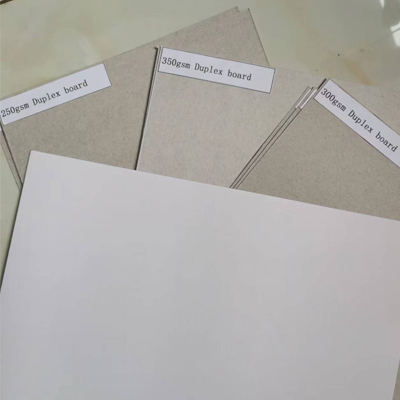

Understanding the technical parameters of duplex board is essential for B2B decision-makers to specify the correct material for their applications. These specifications dictate the board's performance in terms of printability, convertibility, and protective capabilities. Our Duplex Board with Gray back adheres to international testing standards, ensuring reliability and consistent quality.

Typical Product Specification Table: Duplex Board with Gray Back

| Parameter | Unit | Standard Value / Range | Test Standard |

|---|---|---|---|

| Basis Weight (Grammage) | g/m² | 200 - 450 | ISO 536 |

| Thickness (Caliper) | µm | 250 - 650 | ISO 534 |

| Brightness (Top Side) | % ISO | 88 - 92 | ISO 2470 |

| Stiffness (MD) | mN | 150 - 1500 (dependent on grammage) | ISO 2493-1 |

| Stiffness (CD) | mN | 80 - 750 (dependent on grammage) | ISO 2493-1 |

| Smoothness (Bendtsen) | ml/min | 50 - 150 | ISO 8791-2 |

| Moisture Content | % | 6 - 8 | ISO 287 |

| Cobb Value (60s) | g/m² | 25 - 35 | ISO 535 |

These parameters are critical in determining the suitability of the duplex paper stock for specific converting processes such as cutting, creasing, folding, and gluing, as well as its performance on various printing presses. High stiffness ensures packaging integrity, while optimal smoothness and brightness on the coated side are crucial for vibrant color reproduction, making it a preferred choice over basic paper stock.

Market Insights: Global Duplex Board Demand

The global market for duplex board is experiencing steady growth, driven by expanding e-commerce, increasing demand for consumer packaged goods, and the push for sustainable packaging solutions. Industry reports indicate a compound annual growth rate (CAGR) of approximately 4-6% for the paperboard market segment globally, with specific surges in regions with growing manufacturing and retail sectors. The shift towards recycled content in paperboard production, a key feature of many duplex board paper manufacturers, also addresses environmental concerns, contributing to market expansion and brand value.

Application Scenarios and Technical Advantages

The versatility of duplex board allows it to be deployed across a multitude of industries, providing superior performance where both visual appeal and structural integrity are paramount. Its unique construction provides several distinct technical advantages.

Key Application Scenarios:

- Consumer Goods Packaging: From electronics and cosmetics to pharmaceuticals and toys, duplex board is extensively used for folding cartons. Its excellent print surface enables high-quality graphics and branding, while its rigidity protects delicate contents.

- Food & Beverage Packaging (Duplex Board Food Packaging): With appropriate barrier coatings or laminations, duplex board is ideal for food packaging applications, including cereal boxes, frozen food cartons, and confectionery packaging. Compliance with FDA standards for food contact materials is crucial here. The robustness ensures product safety during transit and storage.

- Pharmaceutical Packaging: Precision-printed cartons for medicines demand high graphic fidelity for critical information and anti-counterfeiting measures. The stiffness and smooth surface of coated duplex board grey back meet these stringent requirements.

- Graphic Arts and Printing: Beyond packaging, duplex board is used for book covers, brochures, display cards, and art prints, especially when a sturdy, smooth, and vibrant printing surface is needed on one side, and a more utilitarian back is acceptable. It can even be used for specialized applications resembling both side printing photo paper if laminated or specially treated.

- Footwear and Apparel Packaging: Shoe boxes, garment packaging inserts, and retail gift boxes benefit from the structural strength and aesthetic possibilities of duplex board.

Technical Advantages:

- Superior Printability: The bleached, coated top surface of duplex board provides exceptional ink hold-out and gloss, allowing for sharp, vivid imagery and text with various printing techniques (offset, flexo, digital). This is crucial for brand differentiation.

- High Rigidity and Bulk: The multi-layered construction, often incorporating recycled fibers in the core, imparts significant stiffness and bulk, offering excellent protection for packaged goods against impacts and crushing during handling and transit.

- Cost-Effectiveness: By utilizing recycled fibers for the inner and back layers while maintaining a premium virgin fiber top layer, duplex board offers a cost-effective solution without compromising on the critical aesthetic and protective qualities.

- Versatile Convertibility: It performs exceptionally well in post-printing processes such as die-cutting, creasing, folding, hot foil stamping, and lamination, allowing for complex packaging designs.

- Environmental Benefits: The incorporation of recycled content (common in duplex board with grey back) reduces demand for virgin pulp, minimizes landfill waste, and lowers the carbon footprint associated with paper production, aligning with corporate sustainability goals. This directly contributes to energy saving through reduced virgin fiber processing.

- Moisture and Grease Resistance: With specialized coatings or laminations, duplex board can achieve enhanced barrier properties, providing improved moisture and grease resistance, crucial for many food and cosmetic packaging applications, effectively offering a form of 'corrosion resistance' for the contents.

Vendor Comparison and Customized Solutions

Selecting the right supplier for duplex board is a strategic decision that impacts quality, cost, and supply chain reliability. While numerous duplex board paper manufacturers exist, differentiating factors like consistent quality, technical support, and customization capabilities are critical for B2B procurement.

Key Factors in Vendor Comparison:

| Factor | Shineway Paper Advantage | General Market Consideration |

|---|---|---|

| Quality Consistency | ISO 9001 certified, rigorous QC, uniform grammage & caliper for all duplex board paper. | Varies significantly; risk of batch variations in brightness, stiffness, and printability. |

| Customization & Flexibility | Tailored solutions for specific grammage, stiffness, coating types, and roll/sheet dimensions for duplex paper stock. | Limited options, often requiring large minimum order quantities (MOQs) for non-standard specifications. |

| Certifications & Compliance | FSC, FDA compliance (for food contact grades), ISO 14001 for environmental management. | May lack comprehensive certifications, posing risks for specific applications like duplex board food packaging. |

| Technical Support | Dedicated technical team for application engineering, troubleshooting, and material optimization. | Often basic support; may require in-house expertise for complex issues. |

| Supply Chain & Logistics | Robust global distribution network, efficient lead times, reliable inventory management. | Potential for delays, inconsistent lead times, and less flexible shipping options. |

Our commitment at Shineway Paper extends beyond standard product offerings. We understand that each client has unique requirements, particularly for highly specialized packaging or printing solutions. Therefore, we provide extensive customized solutions for our duplex board.

Customization Capabilities:

- Grammage and Caliper: Precision-tailored to meet specific structural demands, optimizing for carton strength or material yield.

- Surface Coatings: Development of custom coatings for enhanced gloss, matte finish, barrier properties (e.g., grease, moisture for duplex board food packaging), or specialized print finishes to excel beyond typical coated duplex board grey back options.

- Back Side Treatment: Options for custom back finishes beyond the standard grey, including white-back or specific color tints, depending on application needs.

- Roll and Sheet Dimensions: Exact specifications for roll width, core size, or sheet dimensions to seamlessly integrate with client machinery, minimizing waste and improving production efficiency.

- Specialty Additives: Incorporation of additives for increased wet strength, improved stiffness, or antifungal properties for demanding environments.

Our collaborative approach ensures that clients receive a product optimized for their unique operational workflows and end-use requirements, solidifying our position as a leader among duplex board paper manufacturers.

Real-World Application Case Studies

The practical impact of high-quality duplex board is best demonstrated through its successful deployment in challenging industrial applications. These case studies highlight our commitment to delivering material solutions that drive efficiency, enhance product presentation, and ensure reliability.

Case Study 1: Premium Pharmaceutical Packaging

Client Need: A leading pharmaceutical company required a consistent, high-brightness duplex board for their new line of prescription medication packaging. The material needed to offer superior print fidelity for detailed product information and security features, alongside sufficient stiffness to protect delicate glass vials during shipping and handling.

Solution Implemented: We supplied a 280 gsm coated duplex board grey back, specifically engineered with enhanced surface smoothness (Bendtsen 80 ml/min) and a brightness of 91% ISO. This custom specification ensured optimal performance with their high-speed offset printing presses and precision die-cutting machinery. The inherent rigidity of the duplex board, with Stiffness MD 550 mN, provided excellent carton integrity.

Results: The client reported a 15% reduction in printing errors and a noticeable improvement in the visual consistency of their packaging. The enhanced stiffness minimized product damage during transit, leading to significant cost savings in returns and replacements. Our material met all required pharmaceutical packaging standards, ensuring regulatory compliance and strengthening brand trust.

Case Study 2: Sustainable Food Packaging for Frozen Goods

Client Need: A major frozen food manufacturer sought a sustainable and robust packaging solution for a new range of ready-to-eat meals. The material needed to withstand freezer conditions, provide a good moisture barrier, and present a premium, printable surface while incorporating a high percentage of recycled content to meet their corporate sustainability goals, aligning with duplex board food packaging requirements.

Solution Implemented: We collaborated to develop a specialized 350 gsm duplex board with grey back, featuring a proprietary moisture-resistant coating on the printed side. The core layers contained 80% post-consumer recycled fiber, certified by FSC. The Cobb 60s value was reduced to 20 g/m², providing superior resistance to moisture ingress and freezer burn. The smooth, bright coating ensured appetizing product imagery.

Results: The client successfully launched their new product line with packaging that not only met but exceeded their sustainability targets. The improved moisture resistance significantly extended the shelf life of the frozen products, reducing food waste and enhancing consumer satisfaction. The packaging’s rigidity ensured optimal stacking strength in cold storage and retail freezers, demonstrating the versatility of quality duplex board.

These examples underscore our capability to deliver tailored duplex paper stock solutions that address specific industrial challenges, combining technical excellence with practical application benefits.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between duplex board and solid bleached sulfate (SBS) board?

A1: While both offer excellent print surfaces, duplex board typically features a recycled or unbleached fiber core and back, providing cost-effectiveness and good rigidity. SBS board is made entirely from virgin bleached chemical pulp, offering superior whiteness, purity, and strength throughout its cross-section, often at a higher price point. The choice depends on the specific balance of cost, performance, and environmental considerations.

Q2: Can your duplex board be used for food packaging requiring direct food contact?

A2: Yes, our specific grades of duplex board food packaging are manufactured to comply with FDA regulations and other international food safety standards (e.g., EU Regulations). These grades are produced with food-grade virgin pulp on the top layer and often include specialized barrier coatings. Please specify direct food contact requirements during inquiry to ensure appropriate material selection.

Q3: What are the typical lead times for custom orders of duplex board?

A3: For standard stock items, lead times typically range from 7-14 business days. For customized duplex paper stock orders, lead times can vary from 3-6 weeks, depending on the complexity of specifications, order volume, and current production schedules. We strive to provide accurate lead time estimates at the point of order confirmation.

Lead Time and Fulfillment

We maintain strategic inventory levels of our most popular duplex board grades to facilitate rapid dispatch for standard orders. For bespoke requirements, our integrated production planning ensures efficient scheduling, with regular updates provided to clients throughout the manufacturing and logistics phases. Our global logistics network is optimized for timely and secure delivery, minimizing transit times and costs for all regions.

Warranty Commitments

All our duplex board products are backed by a comprehensive quality warranty, guaranteeing adherence to the agreed-upon technical specifications (as per our product specification sheets and ISO standards). In the unlikely event of any material defect or deviation from specified parameters, we commit to prompt investigation, replacement, or appropriate compensation, upholding our reputation for reliability and customer satisfaction.

Customer Support and After-Sales Service

Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-delivery assistance. From initial consultation to after-sales support, clients have direct access to experienced professionals who can provide expert guidance on material selection, application optimization, and troubleshooting. We are committed to fostering long-term partnerships built on trust and consistent performance.

Conclusion

The strategic integration of high-quality duplex board in modern manufacturing and packaging operations offers a clear competitive advantage. Its unique combination of excellent printability, structural integrity, and cost-effectiveness makes it an indispensable material for a wide array of applications, supported by rigorous manufacturing processes and adherence to global quality standards. By partnering with a reputable duplex board paper manufacturer, businesses can ensure reliable supply of materials optimized for their specific needs, driving both operational efficiency and market success.

For further technical details or to discuss your specific requirements, please contact our expert team.

References

- International Organization for Standardization (ISO). ISO 536: Paper and board — Determination of grammage.

- Food and Drug Administration (FDA). Title 21 Code of Federal Regulations, Parts 170-199.

- Forest Stewardship Council (FSC). FSC-STD-01-001 V5-3 EN Forest Stewardship Standard.

- TAPPI (Technical Association of the Pulp and Paper Industry). Various Test Methods (e.g., T 410 for Grammage).

- Pöyry Management Consulting. Global Paper and Board Market Study. (General industry report, specific report title varies by year).

Latest news

-

Duplex Board - High Stiffness, Smooth Print, Food Safe

NewsNov.17,2025

-

Furniture Decoration Paper: Durable, Eco-Friendly, OEM Ready

NewsNov.17,2025

-

Furniture Decoration Paper: Durable, Eco & OEM Designs

NewsNov.17,2025

-

Duplex Board Paper – Coated, High Stiffness, Grey/White Back

NewsNov.17,2025

-

Decor Base Paper for Laminate - High Opacity, Clean Print

NewsNov.17,2025

-

Coated Duplex Board: Stiff, Food-Safe, Grey Back Options

NewsNov.11,2025

Sep . 08, 2025 16:38 Back to list

High-Quality Duplex Board: Coated, Grey Back & Versatile

Understanding Duplex Board: A Foundation for Modern Packaging and Printing

The selection of appropriate materials is paramount in today's demanding industrial and commercial landscape, particularly within the packaging and printing sectors. Among the most versatile and widely utilized materials is the duplex board, a composite paperboard engineered for superior performance. This material, often referred to as duplex board paper, is characterized by its multi-layered structure, typically comprising a bleached, coated surface for optimal printability and a grey or unbleached reverse side for structural integrity and cost efficiency. Its balanced properties make it an indispensable asset for manufacturers seeking both aesthetic appeal and robust protection for their products.

Our discussion will delve into the intricate details of duplex board, from its advanced manufacturing processes and technical specifications to its diverse application scenarios, which include critical areas such as duplex board food packaging. We will also explore the technical advantages that position it as a preferred choice, offer insights into vendor comparison, and highlight customization capabilities, supported by tangible application case studies and adherence to stringent industry standards like ISO and FDA, affirming its authoritative standing in the market.

The Advanced Manufacturing Process of Duplex Board

The production of duplex board is a sophisticated process that integrates multiple stages, each meticulously controlled to ensure the final product meets exacting quality standards. The general process flow emphasizes material purity, structural integrity, and surface finish, crucial for applications ranging from consumer goods packaging to intricate printing projects.

Process Flow Overview:

- Pulp Preparation: This initial phase involves the mechanical and chemical pulping of various fibers. For the bright top layer, virgin pulp (bleached chemical pulp from wood like spruce or pine) is typically used to achieve high whiteness and smooth surface. For the core and back layers, recycled paper stock, often mixed with some virgin fibers for strength, is processed. These materials are meticulously cleaned, screened, and refined to create a homogeneous slurry, ensuring consistent fiber distribution.

- Layer Formation (Multi-Fourdrinier Machine): Unlike single-layer paper, duplex board is formed on multi-fourdrinier machines. Separate headboxes simultaneously lay down distinct layers of pulp onto moving wire meshes. The top layer, destined for printing, receives the high-quality bleached pulp, while subsequent layers, including the bulk core and the grey back (often made from recycled fibers, forming a duplex board with grey back), are formed from lower-grade or recycled pulp. This layering is critical for achieving the dual characteristics of the board.

- Pressing: Once the layers are formed, the wet web of paperboard passes through a series of press rolls. These rolls mechanically remove a significant portion of the water, compacting the fibers and increasing the sheet's density and strength. This stage is crucial for reducing drying energy consumption.

- Drying: The pressed board then enters a sophisticated drying section, where it passes over numerous steam-heated cylinders. Controlled temperature and humidity are vital to gradually remove residual moisture, preventing warping and ensuring dimensional stability. Modern dryers often employ advanced energy recovery systems, aligning with sustainable manufacturing practices and contributing to energy saving.

- Surface Coating: After initial drying, the top surface of the duplex board receives one or more layers of coating. This coating, typically a blend of pigments (e.g., kaolin, calcium carbonate), binders, and additives, is applied via blade or rod coater. The coating enhances brightness, smoothness, ink absorbency, and overall print fidelity, making it ideal for applications requiring high-resolution graphics, such as both side printing photo paper applications or premium packaging. This results in a coated duplex board grey back.

- Calendering: The coated board then goes through calender stacks, which are polished steel rolls. Calendering smooths and densifies the surface further, improving gloss, thickness consistency, and printability. For certain finishes, supercalendering can impart an even higher gloss.

- Slitting and Winding: Finally, the finished duplex board is wound onto large master rolls, which are then precisely slit into narrower rolls or cut into sheets according to customer specifications. This stage requires high precision to minimize waste and ensure uniform dimensions.

Throughout this process, rigorous testing standards, including ISO 9001 for quality management and ISO 14001 for environmental management, are strictly adhered to. Product materials are selected for their sustainability and performance, often including recycled content. The target industries benefiting from this manufacturing precision include general packaging, pharmaceuticals, cosmetics, electronics, and especially duplex board food packaging, where hygiene and barrier properties are critical. The advantages extend to superior print quality, enhanced structural rigidity, and optimal cost-effectiveness due to the strategic use of materials, providing a longer service life for packaged goods.

Technical Specifications and Industry Data for Duplex Board

Understanding the technical parameters of duplex board is essential for B2B decision-makers to specify the correct material for their applications. These specifications dictate the board's performance in terms of printability, convertibility, and protective capabilities. Our Duplex Board with Gray back adheres to international testing standards, ensuring reliability and consistent quality.

Typical Product Specification Table: Duplex Board with Gray Back

| Parameter | Unit | Standard Value / Range | Test Standard |

|---|---|---|---|

| Basis Weight (Grammage) | g/m² | 200 - 450 | ISO 536 |

| Thickness (Caliper) | µm | 250 - 650 | ISO 534 |

| Brightness (Top Side) | % ISO | 88 - 92 | ISO 2470 |

| Stiffness (MD) | mN | 150 - 1500 (dependent on grammage) | ISO 2493-1 |

| Stiffness (CD) | mN | 80 - 750 (dependent on grammage) | ISO 2493-1 |

| Smoothness (Bendtsen) | ml/min | 50 - 150 | ISO 8791-2 |

| Moisture Content | % | 6 - 8 | ISO 287 |

| Cobb Value (60s) | g/m² | 25 - 35 | ISO 535 |

These parameters are critical in determining the suitability of the duplex paper stock for specific converting processes such as cutting, creasing, folding, and gluing, as well as its performance on various printing presses. High stiffness ensures packaging integrity, while optimal smoothness and brightness on the coated side are crucial for vibrant color reproduction, making it a preferred choice over basic paper stock.

Market Insights: Global Duplex Board Demand

The global market for duplex board is experiencing steady growth, driven by expanding e-commerce, increasing demand for consumer packaged goods, and the push for sustainable packaging solutions. Industry reports indicate a compound annual growth rate (CAGR) of approximately 4-6% for the paperboard market segment globally, with specific surges in regions with growing manufacturing and retail sectors. The shift towards recycled content in paperboard production, a key feature of many duplex board paper manufacturers, also addresses environmental concerns, contributing to market expansion and brand value.

Application Scenarios and Technical Advantages

The versatility of duplex board allows it to be deployed across a multitude of industries, providing superior performance where both visual appeal and structural integrity are paramount. Its unique construction provides several distinct technical advantages.

Key Application Scenarios:

- Consumer Goods Packaging: From electronics and cosmetics to pharmaceuticals and toys, duplex board is extensively used for folding cartons. Its excellent print surface enables high-quality graphics and branding, while its rigidity protects delicate contents.

- Food & Beverage Packaging (Duplex Board Food Packaging): With appropriate barrier coatings or laminations, duplex board is ideal for food packaging applications, including cereal boxes, frozen food cartons, and confectionery packaging. Compliance with FDA standards for food contact materials is crucial here. The robustness ensures product safety during transit and storage.

- Pharmaceutical Packaging: Precision-printed cartons for medicines demand high graphic fidelity for critical information and anti-counterfeiting measures. The stiffness and smooth surface of coated duplex board grey back meet these stringent requirements.

- Graphic Arts and Printing: Beyond packaging, duplex board is used for book covers, brochures, display cards, and art prints, especially when a sturdy, smooth, and vibrant printing surface is needed on one side, and a more utilitarian back is acceptable. It can even be used for specialized applications resembling both side printing photo paper if laminated or specially treated.

- Footwear and Apparel Packaging: Shoe boxes, garment packaging inserts, and retail gift boxes benefit from the structural strength and aesthetic possibilities of duplex board.

Technical Advantages:

- Superior Printability: The bleached, coated top surface of duplex board provides exceptional ink hold-out and gloss, allowing for sharp, vivid imagery and text with various printing techniques (offset, flexo, digital). This is crucial for brand differentiation.

- High Rigidity and Bulk: The multi-layered construction, often incorporating recycled fibers in the core, imparts significant stiffness and bulk, offering excellent protection for packaged goods against impacts and crushing during handling and transit.

- Cost-Effectiveness: By utilizing recycled fibers for the inner and back layers while maintaining a premium virgin fiber top layer, duplex board offers a cost-effective solution without compromising on the critical aesthetic and protective qualities.

- Versatile Convertibility: It performs exceptionally well in post-printing processes such as die-cutting, creasing, folding, hot foil stamping, and lamination, allowing for complex packaging designs.

- Environmental Benefits: The incorporation of recycled content (common in duplex board with grey back) reduces demand for virgin pulp, minimizes landfill waste, and lowers the carbon footprint associated with paper production, aligning with corporate sustainability goals. This directly contributes to energy saving through reduced virgin fiber processing.

- Moisture and Grease Resistance: With specialized coatings or laminations, duplex board can achieve enhanced barrier properties, providing improved moisture and grease resistance, crucial for many food and cosmetic packaging applications, effectively offering a form of 'corrosion resistance' for the contents.

Vendor Comparison and Customized Solutions

Selecting the right supplier for duplex board is a strategic decision that impacts quality, cost, and supply chain reliability. While numerous duplex board paper manufacturers exist, differentiating factors like consistent quality, technical support, and customization capabilities are critical for B2B procurement.

Key Factors in Vendor Comparison:

| Factor | Shineway Paper Advantage | General Market Consideration |

|---|---|---|

| Quality Consistency | ISO 9001 certified, rigorous QC, uniform grammage & caliper for all duplex board paper. | Varies significantly; risk of batch variations in brightness, stiffness, and printability. |

| Customization & Flexibility | Tailored solutions for specific grammage, stiffness, coating types, and roll/sheet dimensions for duplex paper stock. | Limited options, often requiring large minimum order quantities (MOQs) for non-standard specifications. |

| Certifications & Compliance | FSC, FDA compliance (for food contact grades), ISO 14001 for environmental management. | May lack comprehensive certifications, posing risks for specific applications like duplex board food packaging. |

| Technical Support | Dedicated technical team for application engineering, troubleshooting, and material optimization. | Often basic support; may require in-house expertise for complex issues. |

| Supply Chain & Logistics | Robust global distribution network, efficient lead times, reliable inventory management. | Potential for delays, inconsistent lead times, and less flexible shipping options. |

Our commitment at Shineway Paper extends beyond standard product offerings. We understand that each client has unique requirements, particularly for highly specialized packaging or printing solutions. Therefore, we provide extensive customized solutions for our duplex board.

Customization Capabilities:

- Grammage and Caliper: Precision-tailored to meet specific structural demands, optimizing for carton strength or material yield.

- Surface Coatings: Development of custom coatings for enhanced gloss, matte finish, barrier properties (e.g., grease, moisture for duplex board food packaging), or specialized print finishes to excel beyond typical coated duplex board grey back options.

- Back Side Treatment: Options for custom back finishes beyond the standard grey, including white-back or specific color tints, depending on application needs.

- Roll and Sheet Dimensions: Exact specifications for roll width, core size, or sheet dimensions to seamlessly integrate with client machinery, minimizing waste and improving production efficiency.

- Specialty Additives: Incorporation of additives for increased wet strength, improved stiffness, or antifungal properties for demanding environments.

Our collaborative approach ensures that clients receive a product optimized for their unique operational workflows and end-use requirements, solidifying our position as a leader among duplex board paper manufacturers.

Real-World Application Case Studies

The practical impact of high-quality duplex board is best demonstrated through its successful deployment in challenging industrial applications. These case studies highlight our commitment to delivering material solutions that drive efficiency, enhance product presentation, and ensure reliability.

Case Study 1: Premium Pharmaceutical Packaging

Client Need: A leading pharmaceutical company required a consistent, high-brightness duplex board for their new line of prescription medication packaging. The material needed to offer superior print fidelity for detailed product information and security features, alongside sufficient stiffness to protect delicate glass vials during shipping and handling.

Solution Implemented: We supplied a 280 gsm coated duplex board grey back, specifically engineered with enhanced surface smoothness (Bendtsen 80 ml/min) and a brightness of 91% ISO. This custom specification ensured optimal performance with their high-speed offset printing presses and precision die-cutting machinery. The inherent rigidity of the duplex board, with Stiffness MD 550 mN, provided excellent carton integrity.

Results: The client reported a 15% reduction in printing errors and a noticeable improvement in the visual consistency of their packaging. The enhanced stiffness minimized product damage during transit, leading to significant cost savings in returns and replacements. Our material met all required pharmaceutical packaging standards, ensuring regulatory compliance and strengthening brand trust.

Case Study 2: Sustainable Food Packaging for Frozen Goods

Client Need: A major frozen food manufacturer sought a sustainable and robust packaging solution for a new range of ready-to-eat meals. The material needed to withstand freezer conditions, provide a good moisture barrier, and present a premium, printable surface while incorporating a high percentage of recycled content to meet their corporate sustainability goals, aligning with duplex board food packaging requirements.

Solution Implemented: We collaborated to develop a specialized 350 gsm duplex board with grey back, featuring a proprietary moisture-resistant coating on the printed side. The core layers contained 80% post-consumer recycled fiber, certified by FSC. The Cobb 60s value was reduced to 20 g/m², providing superior resistance to moisture ingress and freezer burn. The smooth, bright coating ensured appetizing product imagery.

Results: The client successfully launched their new product line with packaging that not only met but exceeded their sustainability targets. The improved moisture resistance significantly extended the shelf life of the frozen products, reducing food waste and enhancing consumer satisfaction. The packaging’s rigidity ensured optimal stacking strength in cold storage and retail freezers, demonstrating the versatility of quality duplex board.

These examples underscore our capability to deliver tailored duplex paper stock solutions that address specific industrial challenges, combining technical excellence with practical application benefits.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between duplex board and solid bleached sulfate (SBS) board?

A1: While both offer excellent print surfaces, duplex board typically features a recycled or unbleached fiber core and back, providing cost-effectiveness and good rigidity. SBS board is made entirely from virgin bleached chemical pulp, offering superior whiteness, purity, and strength throughout its cross-section, often at a higher price point. The choice depends on the specific balance of cost, performance, and environmental considerations.

Q2: Can your duplex board be used for food packaging requiring direct food contact?

A2: Yes, our specific grades of duplex board food packaging are manufactured to comply with FDA regulations and other international food safety standards (e.g., EU Regulations). These grades are produced with food-grade virgin pulp on the top layer and often include specialized barrier coatings. Please specify direct food contact requirements during inquiry to ensure appropriate material selection.

Q3: What are the typical lead times for custom orders of duplex board?

A3: For standard stock items, lead times typically range from 7-14 business days. For customized duplex paper stock orders, lead times can vary from 3-6 weeks, depending on the complexity of specifications, order volume, and current production schedules. We strive to provide accurate lead time estimates at the point of order confirmation.

Lead Time and Fulfillment

We maintain strategic inventory levels of our most popular duplex board grades to facilitate rapid dispatch for standard orders. For bespoke requirements, our integrated production planning ensures efficient scheduling, with regular updates provided to clients throughout the manufacturing and logistics phases. Our global logistics network is optimized for timely and secure delivery, minimizing transit times and costs for all regions.

Warranty Commitments

All our duplex board products are backed by a comprehensive quality warranty, guaranteeing adherence to the agreed-upon technical specifications (as per our product specification sheets and ISO standards). In the unlikely event of any material defect or deviation from specified parameters, we commit to prompt investigation, replacement, or appropriate compensation, upholding our reputation for reliability and customer satisfaction.

Customer Support and After-Sales Service

Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-delivery assistance. From initial consultation to after-sales support, clients have direct access to experienced professionals who can provide expert guidance on material selection, application optimization, and troubleshooting. We are committed to fostering long-term partnerships built on trust and consistent performance.

Conclusion

The strategic integration of high-quality duplex board in modern manufacturing and packaging operations offers a clear competitive advantage. Its unique combination of excellent printability, structural integrity, and cost-effectiveness makes it an indispensable material for a wide array of applications, supported by rigorous manufacturing processes and adherence to global quality standards. By partnering with a reputable duplex board paper manufacturer, businesses can ensure reliable supply of materials optimized for their specific needs, driving both operational efficiency and market success.

For further technical details or to discuss your specific requirements, please contact our expert team.

References

- International Organization for Standardization (ISO). ISO 536: Paper and board — Determination of grammage.

- Food and Drug Administration (FDA). Title 21 Code of Federal Regulations, Parts 170-199.

- Forest Stewardship Council (FSC). FSC-STD-01-001 V5-3 EN Forest Stewardship Standard.

- TAPPI (Technical Association of the Pulp and Paper Industry). Various Test Methods (e.g., T 410 for Grammage).

- Pöyry Management Consulting. Global Paper and Board Market Study. (General industry report, specific report title varies by year).

Next:

Latest news