- Home

- Coated Duplex Board: Stiff, Food-Safe, Grey Back Options

Nov . 11, 2025 20:30 Back to list

Coated Duplex Board: Stiff, Food-Safe, Grey Back Options

Duplex Board is a key solution in the papermaking industry industry, specifically within Cardboard manufacturing and Manufacturing of gray coated whiteboard paper. This article explores how XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Duplex Board Overview

- Benefits & Use Cases of Duplex Board in Manufacturing of gray coated whiteboard paper

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in papermaking industry

- Conclusion on Duplex Board from XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD

Duplex Board Overview

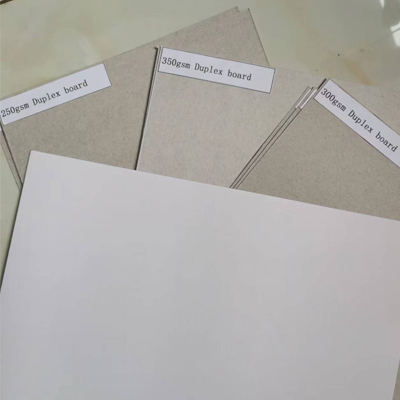

Duplex Board, often called coated duplex board grey back or duplex board with grey back, is a multi-ply paperboard engineered for packaging and high-quality print applications. The product features a white, coated top side for excellent ink holdout and color fidelity, and a sturdy grey reverse—typically made with recycled fiber—for stiffness and cost efficiency. For converters and brand owners, it sits at the intersection of print performance and box-making strength. Typical duplex paper stock ranges from 230–450 gsm with a thickness around 0.3–0.7 mm, ISO top-side brightness of ~78–90%, moisture at 6.5–8.5%, controlled Cobb values, and tight caliper tolerances to ensure reliable runnability across offset, flexo, gravure, and digital lines. XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD supplies duplex board paper tailored to the demands of cardboard manufacturing: consistent formation for clean die-cutting and creasing, smooth coated surfaces for both-side printing where required, and reel or sheet formats for flexible downstream processing. Whether you are sourcing for retail cartons, duplex board food packaging, sleeves, or POP materials, Shineway’s manufacturing know-how delivers repeatable quality that procurement teams can trust.

- Core specs: 230–450 gsm, high stiffness-to-weight ratio, consistent caliper, and optimized coated top side for vivid graphics.

- Print/process compatibility: offset, flexo, gravure, and suitable for lamination, embossing, foiling, and die-cutting.

- Reliable sourcing: a dependable partner among duplex board paper manufacturers, XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD emphasizes stable quality and timely delivery.

Benefits & Use Cases of Duplex Board in Manufacturing of gray coated whiteboard paper

In the Manufacturing of gray coated whiteboard paper, Duplex Board functions as a robust, print-ready substrate for folding cartons, sleeves, tags, and display units. The coated face supports brand-critical graphics and fine type, while the grey back brings stiffness and cost efficiency—ideal for consumer goods, electronics, cosmetics, and duplex board food packaging where presentation and protection both matter. The smooth top coat also enables high ink density and sharp halftones, making it suitable for campaigns that demand near “both side printing photo paper” quality on the exterior panels. XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD enhances converter productivity through controlled sheet flatness, consistent moisture profiles, and precise profiles across the web. That means fewer misfeeds, cleaner cut edges, and reliable scoring. As a result, teams can scale production across multiple SKUs without sacrificing color consistency or die-line accuracy. For buyers who need duplex paper stock that can move seamlessly between printing, varnishing, and finishing—then fold and glue without fiber cracking—Shineway’s duplex board with grey back delivers an attractive balance of strength, printability, and total cost.

- Applications: FMCG cartons, e-commerce inserts, POP displays, sleeves, and food sleeves/outer packs (as specified by local regulations).

- Competitive edge: vivid print on the coated side, strong crease performance, dust-controlled reels/sheets for clean converting, and good laminability.

- Sector expertise: Shineway engineers support press profiling, die-line optimization, and substrate selection to match print, barrier, and finishing needs.

Cost, Maintenance & User Experience

Total cost of ownership with Duplex Board hinges on yield, uptime, and waste reduction. High bulk-to-grammage ratios can achieve required stiffness at lower basis weights, cutting material spend and freight. Tight caliper control and stable moisture reduce print defects, rework, and cutting dust—translating to higher OEE on printing and converting lines. For B2B buyers, the ROI shows up in predictable make-readies, fewer jams, and consistent scoring that minimizes cracking on micro-flute or tight folds. Best practices keep maintenance low: acclimatize pallets 24–48 hours at 15–25°C and 45–60% RH; keep stock wrapped to avoid moisture swings; and clean feed paths to limit dust. Customers in the cardboard manufacturing sector report stable ink densities, smooth lay-flat, and dependable die-cut registration, with duplex paper stock from Shineway supporting quick changeovers between SKUs. Procurement teams value the availability of both reels and sheets, helping align order quantities with press schedules and reducing inventory carrying costs. The result is a balanced TCO where substrate reliability supports faster throughput and consistent pack-out quality at the end of the line.

- ROI drivers: lower basis weight options, reduced waste, fewer stoppages, and improved downstream converting efficiency.

- User feedback: strong printability, clean edges, reliable creasing/folding, and predictable behavior across offset and flexo presses.

Sustainability & Market Trends in papermaking industry

Sustainability continues to redefine packaging choices. Duplex Board supports circularity through high recyclability and efficient fiber use, with the grey back often leveraging recycled content. Regulators and retailers are accelerating shifts away from hard-to-recycle plastics, and brand owners are asking for traceable sourcing, reduction of material intensity, and lower carbon footprints. In parallel, demand grows for paper-based solutions in food service and retail; where required, converters may specify compliant food-contact options or add water-based barrier systems to meet regional regulations. XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD aligns with these trends by prioritizing material efficiency, consistent quality for multiple print methods, and compatibility with finishing processes such as aqueous coatings or film-free embellishments. The company actively tracks evolving standards so buyers can obtain documentation and guidance matched to their markets. As the market favors responsibly sourced duplex board paper and plastic-light designs, Shineway supports packaging engineers with data-driven substrate recommendations and continuous improvement—helping brands scale sustainable packaging without compromising graphic impact or structural integrity.

- Trend drivers: recyclability, lighter grammages, reduced plastics, and compliance with regional food-contact and labeling rules.

- Shineway approach: responsible sourcing focus, support with compliance documentation, and R&D attention to print/barrier compatibility.

Conclusion on Duplex Board from XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD

Duplex Board remains a proven, versatile substrate for papermaking industry applications—especially in Cardboard manufacturing and the Manufacturing of gray coated whiteboard paper. With print-ready coated surfaces and a strong grey back, it balances shelf appeal and mechanical strength across cartons, sleeves, and displays. XINGTAI SHINEWAY PAPER & DECORATION CO.,LTD stands out among duplex board paper manufacturers for dependable quality, consistent converting performance, and support for demanding B2B timelines. Ready to source reliable duplex board paper? Contact us: email: 441835323@qq.com — Visit our website: https://www.shinewaypaper.com

Latest news

-

Duplex Board - High Stiffness, Smooth Print, Food Safe

NewsNov.17,2025

-

Furniture Decoration Paper: Durable, Eco-Friendly, OEM Ready

NewsNov.17,2025

-

Furniture Decoration Paper: Durable, Eco & OEM Designs

NewsNov.17,2025

-

Duplex Board Paper – Coated, High Stiffness, Grey/White Back

NewsNov.17,2025

-

Decor Base Paper for Laminate - High Opacity, Clean Print

NewsNov.17,2025

-

Coated Duplex Board: Stiff, Food-Safe, Grey Back Options

NewsNov.11,2025