- Home

- Top Grey Back Board Producers for Quality and Durability

Nov . 28, 2024 06:50 Back to list

Top Grey Back Board Producers for Quality and Durability

Understanding the Grey Back Board Manufacturing Process

In the world of packaging and paper products, the grey back board, also known as greyboard or chipboard, plays a significant role. Manufactured from recycled paper and cardboard, this sturdy material is commonly used for various applications, including packaging, book covers, and display boards. In this article, we'll dive into the manufacturing process of grey back boards and highlight their importance in various industries.

What is Grey Back Board?

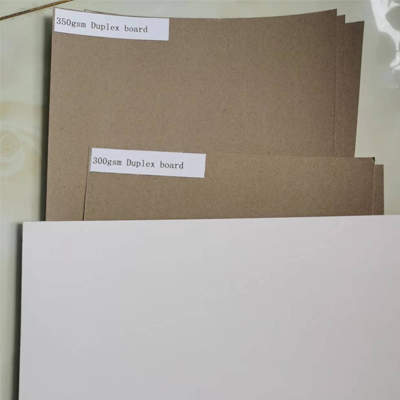

Grey back board is characterized by its thick and rigid structure, typically available in varying thicknesses, ranging from 0.5 mm to several millimeters. The name grey back comes from the board's backside, which retains a greyish hue due to the recycled content. This board is popular for its durability and ability to withstand pressure, making it suitable for multiple uses, from creating boxes to crafting models and other structural applications.

The Manufacturing Process

The production of grey back boards involves several key steps

1. Raw Material Collection The first step in manufacturing grey back boards is gathering raw materials, primarily recycled paper, and cardboard. This sustainable practice reduces waste and contributes to environmental conservation.

2. Pulping The collected materials undergo a pulping process where they are mixed with water and chemicals to break them down into fibers. This mixture is then refined to ensure a uniform fiber consistency, which is crucial for the quality of the final product.

3. Sheet Formation After pulping, the slurry of fibers is poured onto a screen that allows excess water to drain away. This forms a continuous sheet of grey board. The sheet's thickness can be adjusted by varying the amount of material used and controlling the flow of the mixture.

4. Pressing The wet sheets are then pressed to remove additional moisture. This pressing process increases the density and strength of the board. The sheets are subjected to high pressure to ensure they bond well and achieve the desired thickness.

grey back board manufacturer

5. Drying Following pressing, the sheets are dried using hot air or heated rollers. This crucial step reduces the moisture content further, enhancing the board’s durability and preventing warping.

6. Cutting and Finishing After drying, the large sheets of grey back board are cut into desired sizes and finished. Finishing can include surface treatment to improve printability or to create a smoother surface, depending on the intended application.

7. Quality Control Finally, each batch of grey back board is subjected to quality control measures to ensure it meets industry standards. Tests for thickness, strength, and surface quality are performed to guarantee the product's performance in real-world applications.

Applications and Benefits

Grey back board is widely utilized in various sectors, including

- Packaging Its sturdiness makes it perfect for creating boxes, cartons, and protective packaging for fragile items. - Stationery Products The board is commonly used in crafting folders, notebooks, and other stationery items due to its ability to hold shape and resist wear. - Display Products Retailers often use grey back boards for displays and signage, thanks to their print-friendly surface and structural integrity.

The benefits of grey back boards extend beyond just functionality. They are an eco-friendly choice due to their recycled content, and companies can promote sustainability by using these boards in their products.

Conclusion

As industries continue to seek sustainable and cost-effective solutions, grey back board manufacturers are at the forefront of providing high-quality, versatile materials. Understanding the manufacturing process and the applications of grey back boards can help businesses and consumers appreciate the value wrapped in this seemingly simple, yet incredibly useful product. Whether for packaging, crafting, or display purposes, grey back boards remain an essential component of modern manufacturing and design.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025