- Home

- Furniture Decoration Paper That Lasts—Waterproof, OEM?

Oct . 06, 2025 08:55 Back to list

Furniture Decoration Paper That Lasts—Waterproof, OEM?

Furniture Decoration Printing Paper: real-world specs, field notes, and what buyers are asking now

If you work with furniture decoration paper, you already know the market’s moving fast—lighter boards, tighter color tolerances, faster lines. From Xingtai City, Hebei Province, China, this format has quietly become the go-to skin for MDF/particleboard and even RV interiors. To be honest, it’s the small details—ink laydown, porosity control—that separate premium rolls from the rest.

What’s trending (and why it matters)

Woodgrain and stone patterns still dominate, but demand for low-repeat textiles and matte anti-glare finishes is rising. Many customers say color stability through seasonal humidity swings is their #1 headache; surprisingly, resin compatibility and paper porosity solve much of that. Lead times are tightening, so consistent jumbo-roll availability is suddenly a competitive edge.

Core product specs (typical—real-world use may vary)

| Parameter | Typical Value | Notes |

|---|---|---|

| Basis weight (ISO 536) | ≈70–90 gsm | Common for gravure woodgrains |

| Brightness (ISO 2470) | ≈88–92% | Controls ink pop, contrast |

| Opacity (ISO 2471) | ≥92% | Helps hide substrate tone |

| Surface smoothness (PPS/ISO 8791-4) | ≈1.0–1.5 µm | For crisp gravure cells |

| Ink absorption/porosity | Controlled sizing | Minimizes dot gain |

| Roll width | 1270 mm (±3 mm) | Custom widths available |

| Origin | Xingtai, Hebei, China | Stable export capacity |

How it’s made (short version)

- Base paper: engineered fiber blend with controlled ash and sizing for gravure.

- Printing: multi-station gravure (CMYK + spot); Delta E typically ≤1.5 across lots.

- Optional impregnation: melamine/urea-melamine pre-cure for board lamination lines.

- Quality tests: grammage (ISO 536), brightness (ISO 2470), roughness (ISO 8791), Cobb (ISO 535), stiffness (ISO 5629).

- Panel-level checks: Taber abrasion (ASTM D4060), surface resistance (EN 14323) post-lamination.

Applications and advantages

Cabinet doors, wardrobes, wall panels, RV interiors, retail fixtures—anywhere a consistent skin over board is needed. Advantages? Stable print definition, cleaner lamination windows, and fewer color call-backs. It seems that installers appreciate easier trimming around edges; factory managers love the scrap reduction.

Customization

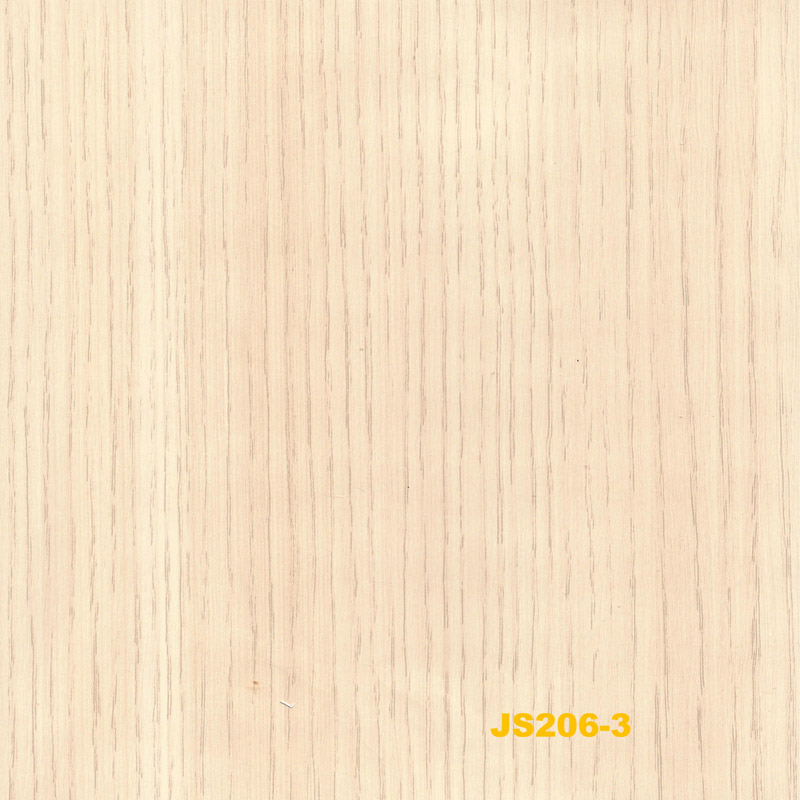

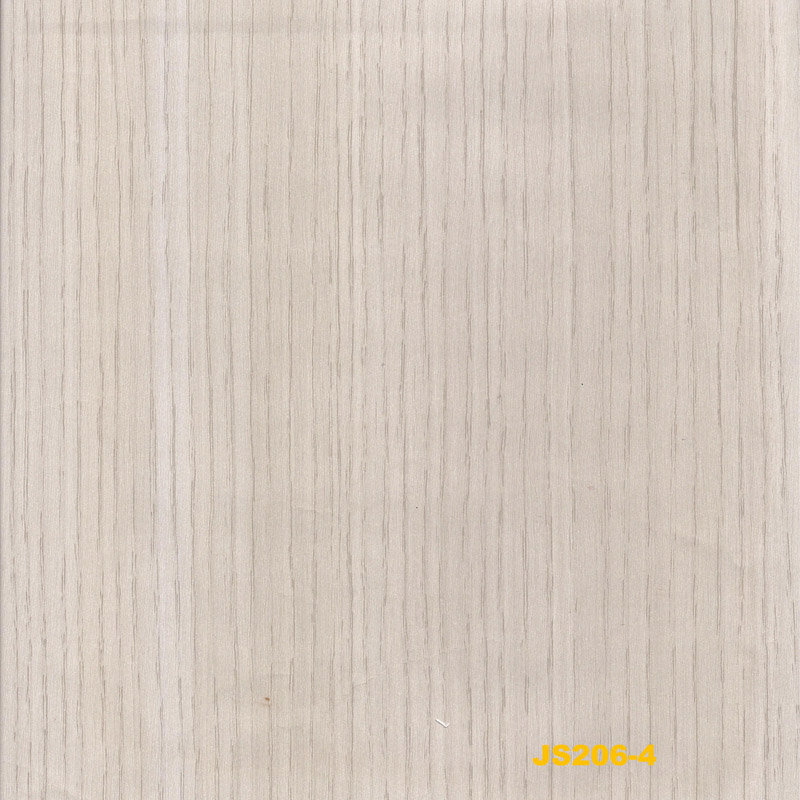

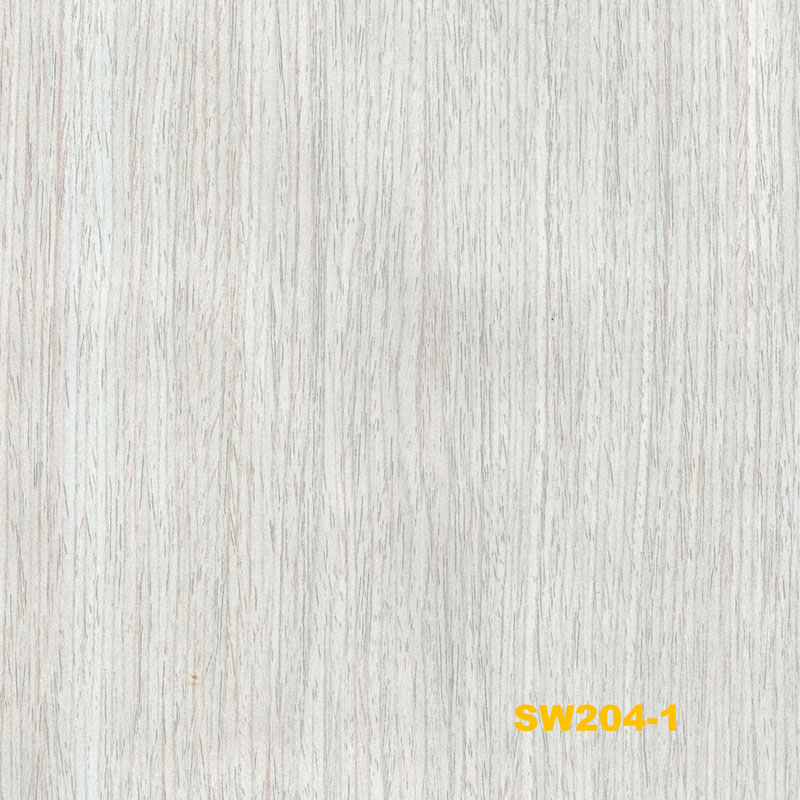

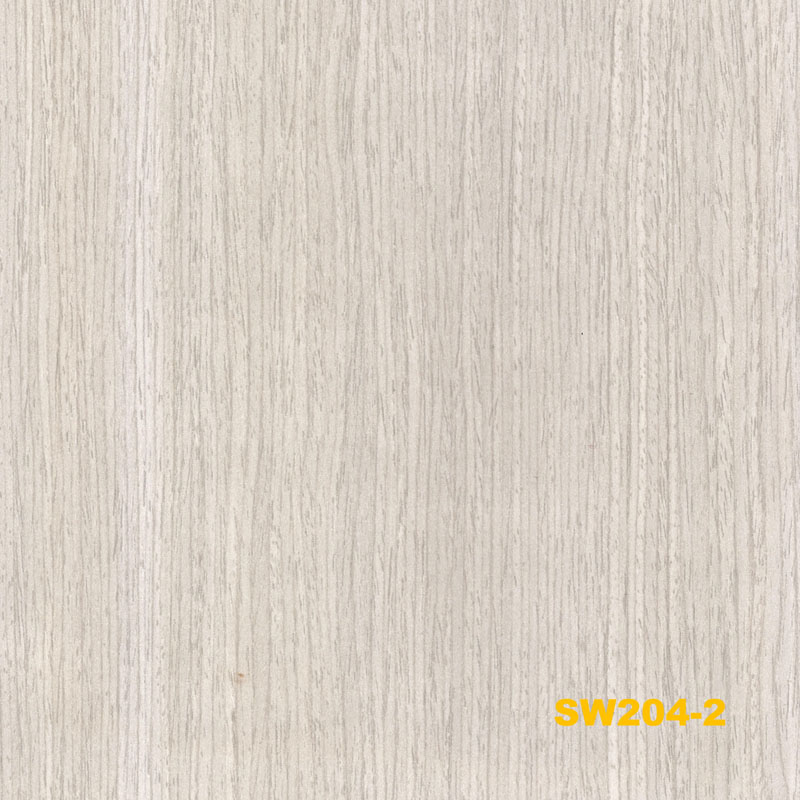

- Patterns: oak, walnut, ash, marble, concrete, textiles, plus brand-matched tones.

- Finish: matte, semi-matte, pore-registered textures (with matching press plates).

- Roll geometry: widths up to 1270 mm; jumbo lengths for fewer splice events.

- Certifications: ISO 9001; FSC mix available on request; low-emission panel targets (E1/E0) after lamination.

Quick case note

A Central European cabinet maker switched to furniture decoration paper with tighter porosity control; color deviation dropped to ΔE 0.9 avg, and line scrap fell ≈18%. After 8-week humidity cycling (23°C/50–85% RH), panels held gloss and edge bond with no visible print bleed.

| Vendor | MOQ | Lead Time | Certs | Customization | Notes |

|---|---|---|---|---|---|

| Shineway (Xingtai) | ≈3–5 tons | 2–4 weeks | ISO 9001, FSC (on request) | Full pattern + width | Stable jumbo rolls, good ΔE |

| Generic Importer | ≈1–2 tons | 4–6 weeks | Varies | Limited library | Check color repeatability |

| Local Printer | Small lots | 1–3 weeks | Depends | Fast tweaks | Watch paper base quality |

Testing, service life, and compliance

Typical indoor service life runs 7–12 years, depending on substrate, resin, and UV exposure. Post-lamination, many fabricators validate Taber abrasion (ASTM D4060), surface properties (EN 14323), and formaldehyde emission class via panel standards (EN 13986/E1). For paper lots, keep a retain sample and test grammage, roughness, and Cobb each delivery—boring, yes, but it saves rework.

Bottom line: If your line fights color drift or resin wet-out, upgrading the furniture decoration paper base—better porosity and smoother PPS—usually pays back within a quarter.

Authoritative citations

- ISO 536: Paper and board — Determination of grammage. https://www.iso.org/standard/7587.html

- ISO 2470-1: Paper, board and pulps — Measurement of diffuse blue reflectance factor. https://www.iso.org/standard/46469.html

- EN 14323: Wood-based panels — Melamine faced boards — Test methods. https://standards.iteh.ai/catalog/standards/cen/c3f3c3f7-

- ASTM D4060: Standard Test Method for Abrasion Resistance by Taber Abraser. https://www.astm.org/d4060

- EN 13986: Wood-based panels for use in construction — Characteristics, evaluation of conformity. https://standards.cen.eu

Latest news

-

High Quality Self Adhesive Cabinet Paper: Durable, Sustainable Finishes for Modern Cabinets

NewsNov.20,2025

-

High Quality Both Side Printing Photo Paper | Superior Double-Sided Prints & Eco Benefits

NewsNov.19,2025

-

The Comprehensive Guide to High Quality Kitchen Table Contact Paper | Durable & Eco-Friendly Solutions

NewsNov.18,2025

-

Durable & Stylish High Quality Contact Paper on Dresser Drawers | Shineway Paper

NewsNov.18,2025

-

Discover High Quality Contact Paper for Kitchen Cabinets – Durable, Eco-Friendly, Affordable

NewsNov.15,2025

-

High Quality Removable Contact Paper For Kitchen Cabinets – Durable & Versatile

NewsNov.14,2025