- Home

- Duplex Paper Production Techniques and Leading Manufacturers in the Industry

Oct . 16, 2024 12:40 Back to list

Duplex Paper Production Techniques and Leading Manufacturers in the Industry

The Duplex Paper Manufacturing Process An Overview of Manufacturers and Their Practices

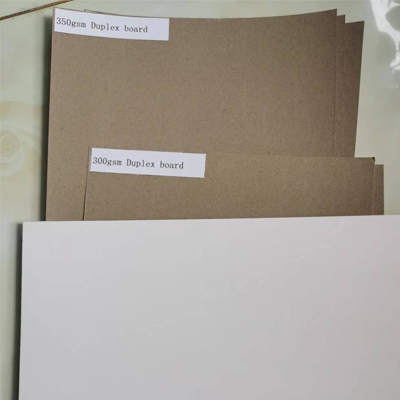

Duplex paper, known for its high-quality surface and excellent printing characteristics, has become a staple in the packaging and printing industries. It typically consists of two layers, or duplex, which provide strength, brightness, and a smooth finish. Understanding the manufacturing process of duplex paper is crucial for both manufacturers and consumers, as it accounts for the quality and performance of the final product.

The Duplex Paper Manufacturing Process

The manufacturing process of duplex paper involves several steps, each critical to ensuring the final product meets industry standards. These steps include pulping, sheet formation, pressing, drying, and coating.

1. Pulping The process begins with the selection of raw materials, predominantly wood pulp or recycled paper. The chosen materials are subjected to mechanical or chemical processes to separate the fibers from lignin and other impurities. This results in a slurry of cellulose fibers, which forms the basis of the duplex paper.

2. Sheet Formation The pulp is diluted with water and fed onto a forming machine, where it is spread evenly to create a thin layer of wet paper. This step is crucial, as an evenly formed sheet ensures uniform quality in the final product. The sheet passes through a series of meshes that help remove excess water.

3. Pressing After the sheet formation, it goes through a series of rollers, known as press sections, which apply pressure to further remove water and flatten the sheet. This step increases the density and strength of the paper, making it more suitable for printing and packaging applications.

4. Drying Once the pressing is complete, the wet paper moves through heated drying cylinders. This removes any remaining moisture, bringing the paper to the required moisture content. The drying process is essential to prevent any issues such as warping or uneven surfaces in the finished product.

5. Coating Many duplex papers undergo a coating process to enhance their surface properties. Coating can improve brightness, printability, and smoothness. The most common coatings are clay-based, providing a glossy or matte finish depending on the customer’s needs. After coating, the paper is often calendered, which involves passing it between rollers to achieve a uniform thickness and improve surface smoothness.

duplex paper manufacturing process manufacturers

6. Cutting and Packaging Finally, the finished duplex paper is cut into large sheets or rolls according to customer specifications. It is then packaged carefully to prevent damage during transportation and storage.

Manufacturers of Duplex Paper

Numerous manufacturers specialize in the production of duplex paper, each employing various techniques and technologies to ensure high-quality outputs. Some key manufacturers include

- WestRock A leading provider in the packaging solutions sector, WestRock uses sustainable practices for producing duplex paper that meets diverse customer needs. Their innovative technologies focus on minimizing waste and maximizing efficiency.

- International Paper Known for its extensive portfolio, International Paper integrates advanced technologies in its duplex paper manufacturing process. They emphasize sustainability, sourcing raw materials responsibly, and continuously improving quality control processes.

- Mondi Group This manufacturer is renowned for its environmentally friendly approach, emphasizing the use of renewable resources and recycling in its duplex paper production. Mondi's advanced coating processes result in top-notch surface quality and performance.

- Sappi Focusing on innovation and sustainability, Sappi combines traditional paper-making methods with modern technology. Their duplex papers are widely used in high-end printing applications due to their superior quality.

Conclusion

The duplex paper manufacturing process combines careful selection of raw materials, precise mechanical operations, and rigorous quality control to produce a product that meets the high standards of today’s packaging and printing industries. The choice of manufacturers plays a significant role in determining the quality of duplex paper, and those who adopt sustainable practices and cutting-edge technologies are likely to lead the market. As the demand for eco-friendly packaging solutions continues to rise, the duplex paper industry is positioned to grow, providing manufacturers with numerous opportunities to innovate and improve their processes.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025