- Home

- duplex paper manufacturing process exporter

Dec . 19, 2024 03:52 Back to list

duplex paper manufacturing process exporter

The Duplex Paper Manufacturing Process An Overview for Exporters

Duplex paper, known for its high-quality finish and stiffness, is widely used in various applications such as packaging, printing, and crafting. The manufacturing process of duplex paper is intricate and involves several stages to ensure the final product meets international standards of quality. This article provides an overview of the duplex paper manufacturing process, making it valuable for exporters in understanding the product they deal with.

What is Duplex Paper?

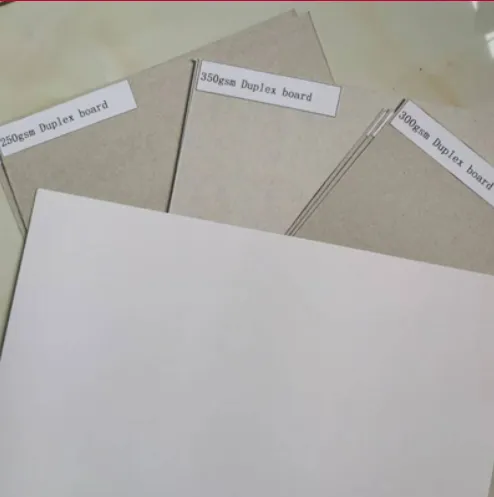

Duplex paper is a type of paperboard, primarily composed of two layers. It generally has a smooth surface on one side (coated) and a rough surface on the other (uncoated). The coated side is often used for printing, providing excellent image quality, while the uncoated side is useful for various industrial applications. The inherent strength and versatility of duplex paper make it an ideal choice for manufacturers and businesses worldwide.

The Manufacturing Process

The production of duplex paper typically follows several key stages outlined below

1. Wood Pulp Preparation The manufacturing process begins with wood pulp, which is derived from wood chips. These wood chips go through a chemical or mechanical pulping process to break down the fibers. The quality of the pulp is crucial, as it directly affects the durability and finish of the duplex paper.

2. Pulping Process In the pulping process, the wood chips are cooked with chemicals, which help to separate the cellulose fibers from lignin and other impurities. After cooking, the mixture is washed to remove any residual chemicals and then bleached to achieve the desired whiteness.

3. Sheet Formation Once the pulp is prepared, it is mixed with water to create a slurry. This slurry is then spread onto a moving wire screen, where the water drains away, leaving behind a mat of fibers. This mat is pressed and dried to form a continuous sheet of paper. The thickness of the sheet can be adjusted based on the desired specifications of the duplex paper.

4. Coating After the paper sheet is dried, it is coated to enhance its surface quality. The coating process involves applying a mixture of pigments and binders to the paper’s surface, which creates a smooth and glossy finish. This step is particularly important for the side that will receive printing, as it improves ink adhesion and vibrancy.

duplex paper manufacturing process exporter

5. Calendering Following coating, the paper is passed through calendering machines that use rollers to smooth and compress the sheets. This step allows for better surface smoothness and thickness uniformity, essential for high-quality printing and packaging applications.

6. Cutting and Packing After the duplex paper is produced, it undergoes cutting into sheets or rolls, depending on market demand. The final product is thoroughly inspected for quality control before being packaged. Proper packing is crucial for maintaining the integrity of the duplex paper during transportation, especially for exporters.

Export Considerations

Exporters dealing with duplex paper should be aware of several factors that influence the market

- Quality Standards International buyers often expect duplex paper to meet specific quality standards. Adhering to standards such as FSC (Forest Stewardship Council) certification can boost credibility and acceptance in global markets.

- Customization Different markets may require customized sizes, weights, and finishes. It is essential for exporters to have the capability to adapt their manufacturing processes to meet diverse customer needs.

- Logistics and Distribution Export entails complex logistics, including transportation, customs clearance, and distribution. Having a reliable logistics partner can help streamline the process and ensure products reach their destinations on time.

- Market Trends Being aware of market trends such as the increasing demand for sustainable and eco-friendly packaging solutions can help exporters align their production and marketing strategies accordingly.

Conclusion

The duplex paper manufacturing process is a blend of technology and craftsmanship, yielding a versatile product that plays a crucial role in various industries. For exporters, understanding this process not only provides insights into product quality but also informs strategies for meeting international market demands. By focusing on quality, customization, and efficient logistics, exporters can ensure the successful distribution of duplex paper globally, catering to the evolving needs of their customers.

Latest news

-

Premium Decor Base Paper for Wallpapers & Crafts

NewsAug.04,2025

-

Premium Duplex Board Paper GPT-4 Turbo Enhanced for Packaging

NewsAug.03,2025

-

Premium Decor Base Paper | GPT-4-Turbo Enhanced | Durability

NewsAug.02,2025

-

Premium Decor Base Paper: High-Durability & Eco-Friendly Substrate

NewsAug.01,2025

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025