- Home

- Duplex Board Price Comparison from Top Manufacturers in the Industry

Dec . 04, 2024 16:05 Back to list

Duplex Board Price Comparison from Top Manufacturers in the Industry

Understanding Duplex Board Price and Manufacturers A Comprehensive Overview

Duplex board, a popular choice for the packaging and printing industries, is a type of paperboard that is known for its versatility, durability, and cost-effectiveness. It is primarily made from recycled fibers, making it an environmentally preferable option for various applications. As businesses prioritize sustainable solutions, the demand for duplex board has increased significantly. This article will explore the factors affecting duplex board prices, the nuances of selecting a reliable manufacturer, and the overall market trends.

What is Duplex Board?

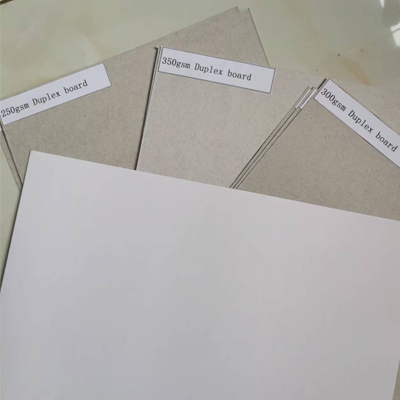

Duplex board is characterized by its two-layer structure, which consists of a white-coated front and a gray back. This composition provides an excellent surface for printing while maintaining significant strength. Commonly used in the production of cartons, boxes, and display materials, duplex board is favored for its ability to deliver high-quality prints that attract consumers. The paperboard's thickness typically ranges from 200 to 800 gsm (grams per square meter), catering to various needs in the packaging sector.

Factors Influencing Duplex Board Prices

1. Raw Material Costs The primary component of duplex board is recycled paper. Fluctuations in the prices of pulp and paper due to supply and demand dynamics directly impact the cost of duplex boards. Additionally, other raw materials such as chemicals used in the coating process can also influence pricing.

2. Manufacturing Processes Different manufacturers employ varying production techniques, which can affect the final price. Advanced technologies and automated processes may increase production efficiency but can also increase investment costs, passing some of that expense onto consumers.

3. Geographic Location The cost of duplex boards can vary significantly based on the location of the manufacturer. Shipping and handling expenses vary by region, and manufacturers close to major markets may benefit from reduced logistics costs. Conversely, those in remote areas may experience higher distribution costs, which can be reflected in pricing.

4. Market Demand Seasonal trends and industry demands often affect the price of duplex board. For example, during periods of increased retail activity (like the holiday season), demand for packaging materials typically surges, leading to potential price increases.

5. Quality and Specifications Prices also differ based on the specifications required by clients. For instance, boards with higher grammage, superior gloss finishes, or eco-friendly certifications may command higher prices. Companies seeking bespoke solutions often find that customization influences overall costs significantly.

duplex board price manufacturer

Choosing the Right Manufacturer

Selecting a dependable duplex board manufacturer is crucial for businesses looking to maintain product quality and supply chain efficiency. Here are some criteria to consider

1. Reputation and Experience A manufacturer with a proven track record and positive industry reputation is more likely to deliver consistent quality. Research potential suppliers by examining customer testimonials and case studies.

2. Certifications and Compliance Ensuring that a manufacturer complies with industry standards (such as ISO certifications) and environmental regulations can be critical in maintaining brand integrity and sustainability commitments.

3. Range of Products Opt for manufacturers that offer a diverse range of duplex boards. The ability to access various thicknesses, coatings, and customizations can greatly benefit businesses with unique requirements.

4. Customer Service Reliable customer support can make a significant difference, especially when dealing with large orders or complex projects. Manufacturers who are responsive and attentive to client needs can help ensure smooth operations.

5. Pricing and Delivery While cost is a crucial factor, balance it with quality. It’s essential to obtain quotes from multiple manufacturers and evaluate lead times to ensure timely delivery aligns with your project schedules.

Conclusion

Duplex board plays a vital role in modern packaging solutions, driven by its versatility and sustainability. Understanding the factors that influence duplex board prices and choosing the right manufacturer are essential steps for businesses aiming to leverage this valuable material. By being well-informed about market dynamics and supplier capabilities, companies can make strategic decisions that align with their operational goals and customer needs. As demand for eco-friendly packaging grows, investing in high-quality duplex board solutions will undoubtedly contribute to a brand's competitive advantage.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025