- Home

- Duplex Board Production Techniques and Applications in the Packaging Industry

Oct . 02, 2024 05:37 Back to list

Duplex Board Production Techniques and Applications in the Packaging Industry

The Duplex Board Manufacturing Process

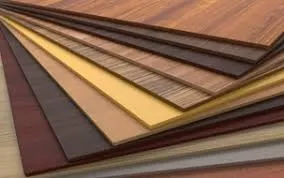

Duplex board is a type of paperboard that has gained increasing prominence in various industries due to its excellent strength, lightweight nature, and eco-friendliness. The manufacturing process of duplex board involves several stages, each critical to producing a high-quality product suitable for various applications, including packaging, printing, and graphical arts.

The process begins with the selection of raw materials. Duplex boards are primarily made from recycled paper and wood pulp. The quality of the raw materials heavily influences the final product's characteristics, such as thickness, brightness, and durability. The recycled paper is sourced from post-consumer waste, which emphasizes sustainability and helps reduce landfill waste.

Once the raw materials are selected, they are prepared for pulping. This involves a mechanical or chemical process that breaks down the paper fibers into a slurry. Chemical pulping is often preferred for producing duplex boards as it yields a cleaner and more consistent pulp. The pulp is then washed and refined to enhance fiber bonding properties.

Following pulping, the slurry is mixed with additives such as fillers, dyes, and binding agents to achieve desired qualities such as brightness and opacity. Common fillers include calcium carbonate and clay, which improve printability and reduce costs. The mixture is then transported to the paper machine, where it is transformed into a continuous sheet.

duplex board manufacturing process products

In the wet end of the paper machine, water is drained from the slurry, and the remaining fiber mat is pressed to remove excess moisture. The mat is then dried using heated rollers, which reduces its moisture content and solidifies its structure. This stage is crucial, as it impacts the board's final strength and texture.

Once dried, the duplex board undergoes a coating process. A layer of clay or a similar coating material is applied to one or both sides of the board, enhancing its smoothness and printing characteristics. The coated board is then calendered, passed through rollers that further smooth and compact the material.

Finally, the duplex board is cut into sheets or rolls, packed, and prepared for shipping. Quality control tests are conducted throughout the manufacturing process to ensure that the finished product meets industry standards for thickness, strength, and finish.

In conclusion, the duplex board manufacturing process is a sophisticated blend of modern technology and sustainable practices. The result is a versatile product that plays a vital role in the packaging sector, offering both performance and environmental benefits. As industries continue to prioritize sustainability, the demand for duplex board is expected to grow, showcasing its importance in our eco-conscious world.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025