- Home

- Duplex Board for Food Packaging & Printing - Why Us?

Oct . 16, 2025 21:30 Back to list

Duplex Board for Food Packaging & Printing - Why Us?

A Field Note on duplex board: specs, real-world use, and what buyers actually ask

If you’ve handled folding cartons this week—shoe boxes, cake boxes, a cosmetic kit—chances are you’ve touched duplex board. It’s the unglamorous hero of retail packaging. And, to be honest, the category is evolving faster than people think: lighter weights with higher stiffness, smarter coatings, and, increasingly, verified recycled content. From Xingtai City, Hebei Province in China, Shineway Paper’s “Duplex Board with Gray Back” has been making the rounds in buyer shortlists—partly because they keep the portfolio tight and the QC surprisingly strict, or so many customers say.

What it is (and what matters)

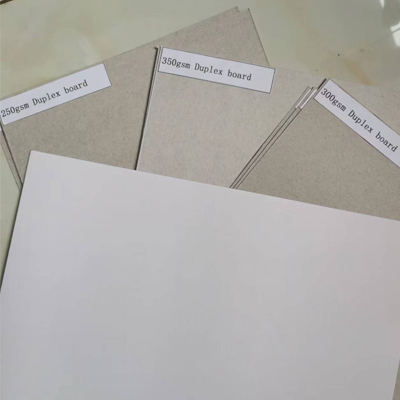

Duplex board is a multi-ply paperboard with a white coated top layer and, commonly, a gray or white back. Shineway offers LWC and HWC coatings from 230–450 gsm, in standard sizes 1092×787 mm, 1194×889 mm, 610×860 mm, and 31×43". In real-world use, print converters want three things: stable caliper, clean surface for CMYK + spot varnish, and a back that behaves (gray back is budget-friendly; white back for higher-end cosmetics or pharma sleeves).

Typical product specs (lab vs shop-floor)

| Parameter | Duplex Board with Gray Back (≈) | Standard/Method |

|---|---|---|

| Grammage | 230–450 gsm | ISO 536 |

| Caliper | 0.30–0.70 mm (range varies by gsm) | ISO 534 |

| Brightness (top) | ≈ 78–88% ISO | ISO 2470 |

| Cobb (top/30) | 20–35 g/m² | ISO 535 |

| Burst (Mullen) | ≈ 180–350 kPa (by grade) | ISO 2758 |

| Moisture | 6.5–8.5% | ISO 287 |

Process flow (short version)

Materials: recycled fibers for the middle plies; bleached hardwood kraft pulp for the top layer; mineral coatings (LWC/HWC). Methods: multi-ply formation, blade coating, calendering, sheet cutting. Testing: grammage, caliper, stiffness (ISO 5628), Cobb, brightness, tensile (ISO 1924), rub/wet-rub (TAPPI T830/T530). Service life: around 12–24 months if stored at 20–65% RH, 10–25°C; real-world use may vary.

Use cases, industries, and why people pick it

Duplex board shows up in footwear cartons, bakery/cake boxes, takeaway food sleeves, toys, FMCG display outers, and a lot of private-label cosmetics. Advantages? Printability, cost control, decent die-cut performance, and enough stiffness-to-weight ratio to keep logistics sensible. Many converters say HWC on top dramatically reduces ink consumption for flood-coats—surprisingly noticeable on deep reds and blues.

Customization (what buyers usually tweak)

- Back color: gray back (value) or white back (premium look).

- Coating weight: LWC vs HWC depending on ink coverage and finish.

- Sheet size: standard cuts or mill-trimmed custom sizes to reduce waste.

- Compliance: FSC Mix claim, ISO 9001/14001; migration/odor tests for food sleeves (ask for reports).

- Special: anti-curl control and tighter moisture windows for monsoon-season runs—small thing, big impact.

Vendor snapshot (quick compare)

| Vendor | Core Range | Certs | Lead Time (≈) | Notes |

|---|---|---|---|---|

| Shineway Paper (Xingtai, Hebei) | 230–450 gsm, LWC/HWC, gray/white back | ISO 9001, ISO 14001, FSC | 10–20 days | Stable caliper; competitive MOQs |

| Mill A (Asia) | 250–400 gsm | ISO 9001 | 15–25 days | Good brightness; stricter MOQ |

| Trader B | Mixed mills | Varies | Stock-based | Fast spot buys; variable spec |

Two quick case notes

Duplex board 350 gsm HWC, white back: a cosmetics brand cut ink by ~9% on solids, with fewer pinholes in matte varnish—press crew was relieved. 300 gsm gray back for cake boxes: switch from 350 gsm saved ~11% material weight with no denting in transit, after they improved crease matrix settings.

Customer feedback? “Edges die-cut cleaner than our previous lot, less dusting on the feeder.” Not scientific, but it tracks with the lab numbers.

Bottom line: if you need reliable folding cartons without breaking the budget, duplex board with the right coating and moisture controls still punches above its weight.

Authoritative references

- ISO 536, 534, 535, 2470, 2758, 287, 1924: Paper and board test methods.

- FSC Chain of Custody Standard (FSC-STD-40-004) for certified fiber sourcing.

- ECMA/CEPI Cartonboard grades and converting guidelines (industry handbook).

- TAPPI T530/T830: Wet rub and scuff resistance test procedures.

Latest news

-

Duplex Board - High Stiffness, Smooth Print, Food Safe

NewsNov.17,2025

-

Furniture Decoration Paper: Durable, Eco-Friendly, OEM Ready

NewsNov.17,2025

-

Furniture Decoration Paper: Durable, Eco & OEM Designs

NewsNov.17,2025

-

Duplex Board Paper – Coated, High Stiffness, Grey/White Back

NewsNov.17,2025

-

Decor Base Paper for Laminate - High Opacity, Clean Print

NewsNov.17,2025

-

Coated Duplex Board: Stiff, Food-Safe, Grey Back Options

NewsNov.11,2025