- Home

- contact paper for table top manufacturers

Dec . 03, 2024 17:00 Back to list

contact paper for table top manufacturers

Contact Paper for Tabletop Manufacturers A Game Changer in Surface Finishing

In the world of furniture manufacturing, particularly tabletop production, the choice of finishing materials can significantly impact both aesthetics and functionality. One of the emerging trends that has captured the attention of manufacturers is the use of contact paper. This versatile material offers a unique blend of style, durability, and ease of application, making it an attractive option for tabletop manufacturers looking to enhance their product offerings.

What is Contact Paper?

Contact paper, also known as adhesive vinyl or self-adhesive film, is a thin plastic sheet with a sticky backing. It is designed for easy application and can be used to cover a variety of surfaces, transforming them into something new. Although traditionally used for arts and crafts, its potential in the furniture industry has been largely overlooked until recently. With advancements in design and printing technologies, contact paper now comes in a myriad of colors, patterns, and textures, allowing manufacturers to create unique and appealing tabletops.

Advantages for Tabletops

1. Affordability One of the most significant benefits of contact paper is its cost-effectiveness. Manufacturers can offer stylish and modern designs at a fraction of the cost of traditional materials like wood veneers or laminate. This affordability enables the production of attractive tabletops without significantly impacting the price point, allowing for higher sales volumes.

2. Wide Variety of Designs Contact paper comes in an extensive range of designs, from classic wood finishes to vibrant graphic patterns. This variety allows tabletop manufacturers to cater to different consumer tastes and trends. As preferences shift towards personalized and unique furniture pieces, having access to diverse design options can give manufacturers a competitive edge.

3. Ease of Application Applying contact paper is a straightforward process that can be performed quickly and efficiently. Unlike traditional methods that may involve complicated machinery or techniques, contact paper can be cut to size and simply adhered to the tabletop surface. This ease of application supports faster production cycles and can significantly reduce labor costs.

contact paper for table top manufacturers

4. Durability Modern contact paper is designed to be durable and resilient. Many options are waterproof and resistant to scratches and stains, making them ideal for kitchen and dining table applications. This durability ensures that the final product maintains its aesthetic appeal over time, providing added value to both manufacturers and consumers.

5. Sustainability As sustainability becomes an increasingly pressing concern, the use of contact paper can align with eco-friendly practices. Many brands now offer contact paper made from recyclable materials, making it easier for manufacturers to adopt sustainable sourcing practices. Additionally, the lightweight nature of contact paper can reduce transportation costs and emissions.

Challenges and Considerations

While contact paper offers several advantages, it is essential for tabletop manufacturers to consider some challenges. For instance, the longevity of contact paper compared to traditional finishes may be a concern for some consumers. Establishing open and clear communication about maintenance and care instructions can help alleviate these worries. Manufacturers should also ensure that they source high-quality contact paper to guarantee the best results.

Conclusion

As tabletop manufacturers seek innovative ways to stay competitive in an evolving market, contact paper presents a unique opportunity. Its affordability, variety, ease of application, durability, and sustainability profile can transform how tabletops are finished and sold. By embracing this material, manufacturers can not only streamline their production processes but also offer end products that resonate with today's consumers who value both style and functionality.

In summary, contact paper is more than just a crafty tool; it's a game changer for tabletop manufacturers. By integrating this material into their designs, they can meet the demands of a diverse market while being mindful of cost and sustainability. As the industry continues to evolve, those who adopt new technologies and materials like contact paper will be well-positioned to lead in the future of furniture manufacturing.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

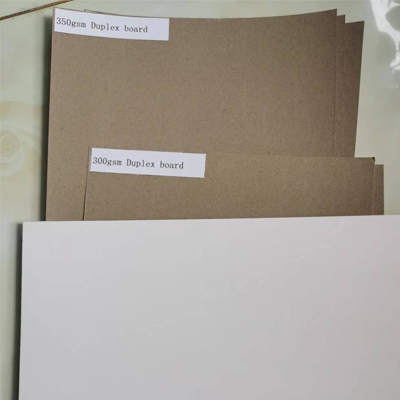

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025