- Home

- contact paper for cabinets wood manufacturer

Oct . 19, 2024 23:33 Back to list

contact paper for cabinets wood manufacturer

Understanding the Importance of Contact Paper for Cabinet Wood Manufacturers

In the competitive world of woodworking and cabinetry, manufacturers continuously strive to innovate and improve their products. One key material that often plays a critical role in enhancing the aesthetics and durability of cabinets is contact paper. This versatile product has become an essential tool for wood manufacturers, significantly impacting the quality and appeal of their finished products.

What is Contact Paper?

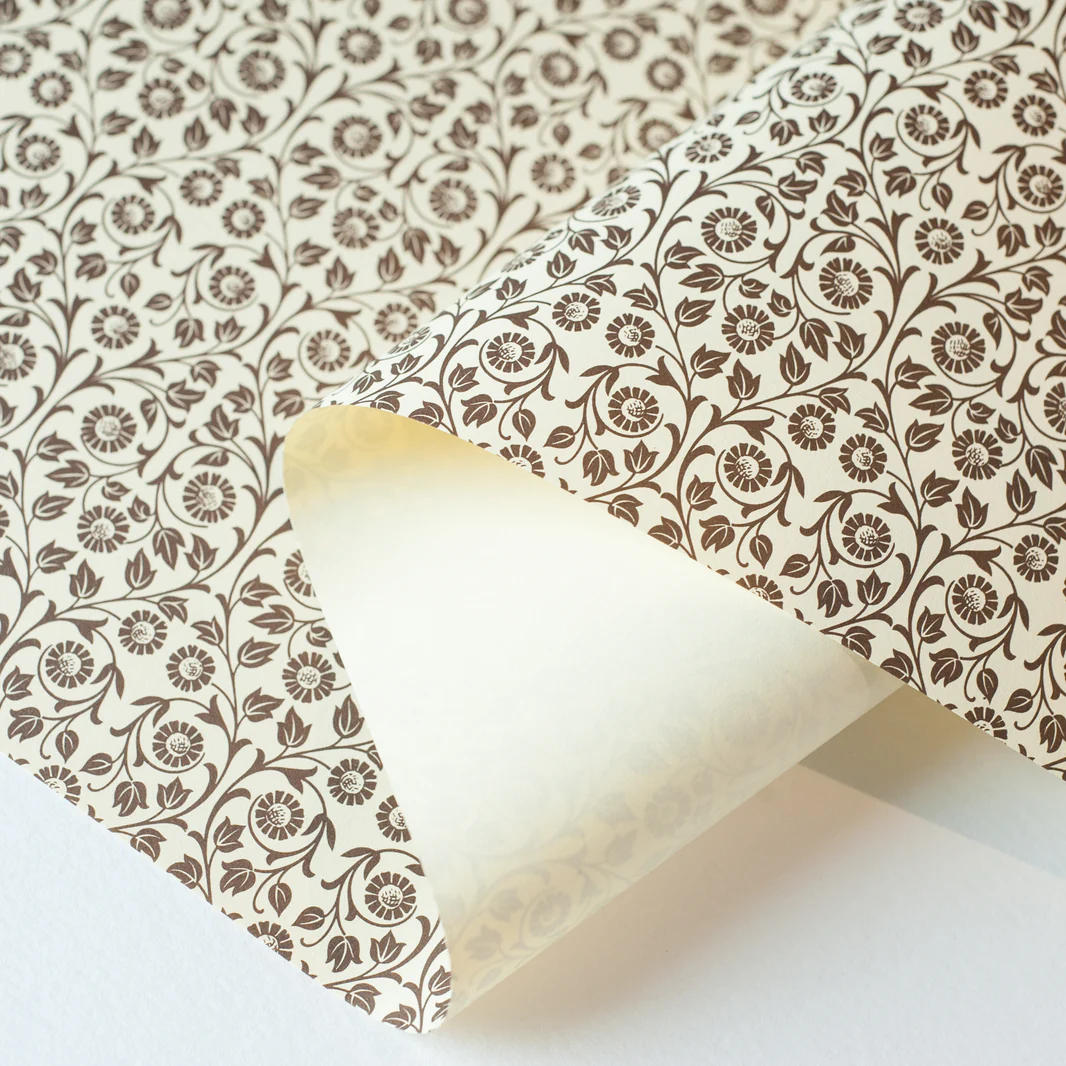

Contact paper, also known as adhesive film or self-adhesive vinyl, is a thin and often decorative surface covering that can be applied to various materials, including wood. It typically consists of a vinyl sheet and a backing that protects the adhesive until it is ready to use. Available in myriad designs, colors, and textures, contact paper allows manufacturers to cater to diverse tastes and preferences, thereby broadening their customer base.

Benefits of Using Contact Paper in Cabinetry

1. Aesthetic Enhancement One of the primary advantages of contact paper is its ability to dramatically enhance the appearance of cabinetry. Manufacturers can choose from a wide range of finishes, including wood grains, solid colors, and unique patterns. By using contact paper, they can mimic high-end wood finishes or even create bold statement pieces, satisfying customer demands for both classic and contemporary designs.

2. Cost-Effectiveness When compared to traditional wood veneers and laminates, contact paper offers a more economical solution for manufacturers. It allows for significant cost savings without compromising on style. This cost-effectiveness is particularly advantageous for manufacturers looking to produce budget-friendly cabinetry options that still look appealing.

contact paper for cabinets wood manufacturer

3. Ease of Application Contact paper is user-friendly and can be applied quickly and efficiently. This ease of use is beneficial for manufacturers looking to streamline their production processes. Unlike more complex finishing methods, such as veneering, contact paper requires minimal tools and can be adjusted or repositioned, reducing the likelihood of waste and errors.

4. Durability and Protection Modern contact papers are designed to be durable and resistant to scratches, moisture, and fading. This quality makes it an ideal option for cabinetry that may be exposed to various environmental conditions, from humidity in kitchens to wear and tear in busy living spaces. Furthermore, the protective layer of contact paper can help shield the underlying wood from damage, extending the lifespan of the cabinets.

5. Sustainability With the rising awareness of environmental issues, many wood manufacturers are seeking sustainable practices. Contact paper can be a greener option since it enables the use of less expensive or recycled materials underneath, reducing the demand for high-quality solid wood. Many brands also produce eco-friendly contact papers, allowing manufacturers to appeal to environmentally-conscious consumers.

Conclusion

In the realm of cabinet wood manufacturing, contact paper is more than just a decorative layer; it is a transformative tool that enhances aesthetics, reduces costs, and increases ease of production. As manufacturers look to differentiate themselves in a crowded market, the strategic use of contact paper can set them apart. It allows for creative freedom while prioritizing efficiency and sustainability. By understanding and harnessing the full potential of contact paper, cabinet manufacturers can meet the evolving needs of modern consumers while also promoting innovation within their craftsmanship.

As this trend continues to grow, it is clear that contact paper will remain a pivotal element in the repertoire of materials utilized by wood manufacturers, shaping the future of cabinetry design and production.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025