- Home

- Manufacturers of Grey Back Coated Duplex Board for Various Packaging Solutions

Nov . 30, 2024 13:10 Back to list

Manufacturers of Grey Back Coated Duplex Board for Various Packaging Solutions

The Evolution and Significance of Coated Duplex Board with Grey Back

Coated duplex board with a grey back is a versatile material widely used in various industries, particularly in packaging and printing. As a sustainable and cost-effective option, its production and applications have evolved significantly over the years. In this article, we will explore what coated duplex board is, its manufacturing process, and its impact on modern packaging solutions.

What is Coated Duplex Board?

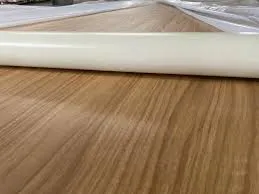

Coated duplex board is a type of paperboard that is made from recycled materials, primarily consisting of two layers a white top layer coated with clay or other compounds for smoothness and printability, and a grey back layer that provides strength and rigidity. The grey back is typically produced using a lower-quality pulp, making it more cost-effective compared to the white top layer. This design allows manufacturers to create an economical product that still meets the demands of high-quality printing and packaging.

Manufacturing Process

The production of coated duplex board involves several key steps. First, recycled paper and pulp are sourced, which are then cleaned and processed to remove impurities. This is crucial to ensure that the quality of the final product meets industry standards. After this, a mixture of recycled fibers is formed into sheets and dried.

Next, the coating process begins. The top layer is coated with a mixture of clay and other materials to achieve a smooth finish that is ideal for printing. The coatings not only enhance the visual appeal of the board but also improve its performance in terms of ink absorption and durability. Once the coating is applied, the sheets are dried again to lock in the finish.

Finally, the coated duplex board is cut, sorted, and packaged for distribution

. Manufacturers focus on quality control during each stage to ensure that the final product meets the needs of various applications, from food packaging to folding cartons.Applications in Different Industries

coated duplex board grey back manufacturers

Coated duplex board is used extensively in several sectors. In the packaging industry, it is favored for its ability to hold shapes and protect contents while offering a high-quality surface for graphics. Retail packaging, luxury boxes, and food packaging often utilize coated duplex board due to its excellent strength-to-weight ratio and printability.

In the printing sector, it serves as a popular substrate for book covers, brochures, and promotional materials. The ability to print high-resolution images and vibrant colors makes it a go-to choice for marketing campaigns.

Moreover, coated duplex board is increasingly recognized for its sustainability. As more companies strive to reduce their environmental impact, using recycled materials in production aligns with eco-friendly practices. This shift towards sustainable options is not only beneficial for the planet but also resonates with consumers who prefer to support brands that prioritize environmental responsibility.

The Future of Coated Duplex Board

As the demand for sustainable packaging solutions grows, the future of coated duplex board looks promising. Manufacturers are investing in technological advancements to enhance the quality and sustainability of their products. Innovations such as improved recycling techniques and new coating materials are being explored to make the production process even more eco-friendly.

Additionally, the rise of e-commerce has increased the need for durable and attractive packaging solutions. Retailers are always on the lookout for packaging materials that can withstand the rigors of shipping while still looking appealing on the shelves. Coated duplex board fits this requirement perfectly, offering strength along with aesthetic value.

Conclusion

Coated duplex board with a grey back is more than just a packaging material; it is a reflection of the industry's commitment to quality, sustainability, and innovation. As manufacturers continue to evolve their practices and adapt to market demands, coated duplex board will remain a staple in the packaging and printing industries, playing a vital role in shaping the future of sustainable solutions. With its combination of practicality and environmental awareness, it is poised to stay relevant in an ever-changing market landscape.

Latest news

-

High-Quality Furniture Decoration Paper for Stylish Interiors

NewsJul.24,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025