- Home

- Manufacturer of Grey Back Box Boards for Various Applications and Uses

Dec . 09, 2024 23:28 Back to list

Manufacturer of Grey Back Box Boards for Various Applications and Uses

The Essential Guide to Box Board Grey Back Manufacturers

Box board, specifically in the grey back variant, has gained significant traction in various industries due to its unique properties and versatile applications. This type of board is particularly favored for packaging solutions, crafting, and even structural applications where durability and strength are essential. In this article, we delve into the importance of box board grey back manufacturers and explore what sets them apart in the competitive landscape of materials production.

Understanding Box Board Grey Back

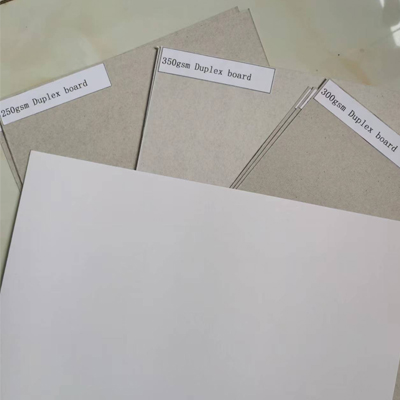

Box board grey back is characterized by its sturdy construction and distinct grey underside, which is typically created using recycled materials. The grey backing enhances the board's strength while providing a cost-effective solution for various packaging needs. Commonly, it is used in the production of folding cartons, cigarette boxes, and various types of retail packaging. The choice of grey back adds durability and a level of aesthetic appeal, which makes it a preferred choice among manufacturers and brands alike.

Why Choose a Reliable Manufacturer?

When it comes to sourcing box board grey back, choosing a reputable manufacturer is crucial. Quality control, material sourcing, and production expertise significantly influence the final product's durability and usability. Here are some key reasons why partnering with a reliable manufacturer is essential

2. Sustainability Practices Many leading manufacturers focus on sustainable practices, utilizing recycled materials in their production processes, which is increasingly important in today's eco-conscious market.

3. Customization Options A good manufacturer will offer customization options, allowing businesses to specify dimensions, thickness, and surface finishes that align with their packaging needs.

box board grey back manufacturer

4. Technical Expertise Experienced manufacturers possess in-depth knowledge of materials and production techniques, enabling them to provide valuable insights and recommendations for optimal usage.

5. Efficient Supply Chain A well-organized manufacturing operation ensures timely delivery and consistent supply, reducing downtime and ensuring businesses can meet their production schedules.

The Manufacturing Process

The process of manufacturing box board grey back involves several stages. Initially, recycled paper pulp is processed to create sheets of board. This pulp is then formed into large sheets, which are dried and treated to enhance its properties. The grey backing is applied using a series of presses, which also contribute to the board's structural integrity. After undergoing rigorous quality checks, the board is cut and packaged, ready for distribution.

Applications of Box Board Grey Back

The versatility of box board grey back makes it suitable for a myriad of applications. It is widely used in

- Retail Packaging Many brands opt for grey back for their packaging solutions, as it provides a reliable protective layer while maintaining aesthetic appeal. - Point-of-Sale Displays The sturdy nature of grey back makes it an excellent choice for displays that require durability and visual impact. - Food Packaging Certain food items require robust packaging solutions to ensure freshness and protect the product during transit. Grey back box board meets these requirements efficiently. - Craft Projects Artisans and hobbyists frequently utilize grey back box board for various crafts, thanks to its smooth surface and easy handling characteristics.

Conclusion

Box board grey back manufacturers play a pivotal role in the supply chain of packaging and materials production. By combining quality, sustainability, and innovation, these manufacturers cater to a diverse range of industries and applications. As businesses continue to seek reliable packaging solutions, the importance of choosing the right manufacturer cannot be overstated. Ultimately, investing in high-quality box board grey back can enhance a brand's reputation, ensuring that products arrive in optimal condition, ready for consumers. For businesses looking to make an informed choice, engaging with reputable manufacturers is the first step toward achieving packaging excellence.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025