- Home

- box board grey back exporter

Oct . 02, 2024 07:43 Back to list

box board grey back exporter

The Rise of Box Board Grey Back Exporters

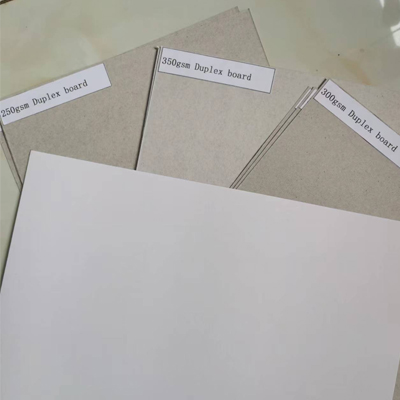

In recent years, the packaging industry has experienced a remarkable transformation, especially with the growing demand for sustainable and versatile materials. Among these materials, box board grey back has gained considerable attention, leading to an increase in exporters specializing in this product. This article delves into the significance of box board grey back, the reasons for its rising popularity, and the impact of exporters in this sector.

The Rise of Box Board Grey Back Exporters

One of the key factors contributing to the increasing demand for box board grey back is the global shift towards eco-friendly packaging solutions. As consumers become more environmentally conscious, they seek options that minimize waste and can be recycled or composted. Box board grey back meets these criteria; it is made from recycled fibers and is fully recyclable itself. This sustainability aspect appeals to both manufacturers and consumers alike, making it a preferred choice over plastic and other non-biodegradable materials.

box board grey back exporter

Furthermore, the versatility of box board grey back sets it apart from other packaging materials. It can be easily cut, folded, and printed on, allowing manufacturers to create customized packaging solutions that cater to a variety of products. From food and beverages to electronics and cosmetics, box board grey back can adapt to numerous industries, facilitating creative packaging designs that attract consumers.

As a result of this rising demand, exporters of box board grey back have flourished. These exporters play a crucial role in ensuring that quality materials reach manufacturers across the globe. Many exporters are focusing on streamlining their supply chains and adopting efficient logistics to deliver their products on time. This not only enhances customer satisfaction but also ensures a steady flow of materials necessary for production.

Additionally, exporters are increasingly investing in technology and innovation to improve product quality and reduce environmental impact. Enhanced manufacturing processes have led to stronger and lighter box board grey back, which further supports sustainable practices in packaging. By collaborating with manufacturers and stakeholders, these exporters are driving the evolution of the packaging industry toward a more sustainable future.

In conclusion, box board grey back is becoming a staple in the packaging sector due to its sustainability, versatility, and cost-effectiveness. The surge in exporters specializing in this material is a testament to the growing need for eco-friendly packaging solutions. As consumers continue to prioritize sustainability, the role of box board grey back exporters will remain pivotal in shaping the future of the packaging industry.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025