- Home

- Innovative Adhesive Paper Solutions for Furniture Manufacturing and Design

Oct . 21, 2024 20:37 Back to list

Innovative Adhesive Paper Solutions for Furniture Manufacturing and Design

The Transformative Role of Adhesive Paper in Furniture Manufacturing

In the contemporary furniture manufacturing industry, the quest for innovative solutions that enhance both aesthetics and functionality is ever-present. One such solution that has gained significant traction is adhesive paper. This versatile material is revolutionizing the way furniture manufacturers design, produce, and finish their products, offering benefits that extend beyond mere convenience.

Understanding Adhesive Paper

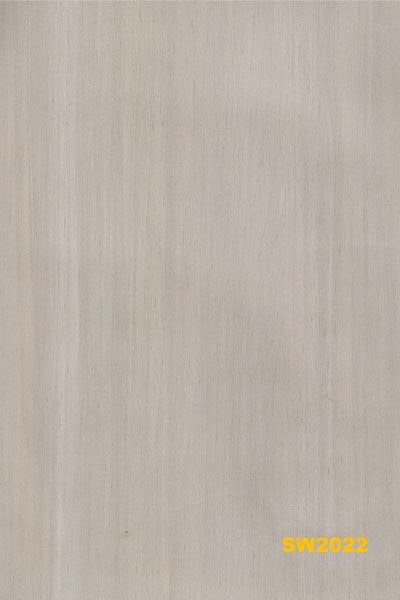

Adhesive paper, also known as self-adhesive laminate or adhesive-backed films, is a type of paper or synthetic material coated with a sticky layer on one side. This allows it to adhere to various surfaces without the need for additional adhesives. Typically, it comes in a myriad of colors, patterns, and textures, making it an attractive choice for designers who want to create striking furniture pieces that stand out in a competitive market.

Advantages in Furniture Manufacturing

1. Cost Efficiency One of the primary benefits of using adhesive paper is its cost-effectiveness. Traditional techniques, such as veneering or laminate application, often require significant time and labor, leading to higher production costs. In contrast, adhesive paper can be quickly and easily applied, reducing labor costs and production times significantly.

2. Versatility Adhesive paper can be applied to a variety of substrates, including wood, MDF, particleboard, and even metal. This versatility allows manufacturers to use it for an array of applications, from cabinetry to tabletops, providing endless design possibilities. Furthermore, it can be easily cut to any size or shape, enabling custom designs that cater to the specific needs of clients.

3. Aesthetic Appeal With the ability to mimic various materials such as wood grain, stone, or even intricate patterns, adhesive paper allows furniture manufacturers to create visually appealing products without the weight and cost associated with actual materials. Manufacturers can create stunning designs that are on-trend and appealing to consumers, improving their market reach.

Sustainability Through Smart Selection

adhesive paper for furniture manufacturer

With the global push towards sustainability, furniture manufacturers are also finding adhesive paper to be a key player in eco-friendly initiatives. Many adhesive papers are produced from recycled materials, and their lightweight nature means reduced transport emissions. Additionally, because adhesive paper can renew aging furniture or surfaces, it promotes a culture of reuse and recycling, minimizing waste.

Challenges and Considerations

Despite its many advantages, manufacturers must also be aware of potential challenges associated with adhesive paper. One of the primary concerns is durability. Depending on the quality of the adhesive paper used, some products may not stand up well to wear and tear over time. To mitigate this risk, manufacturers need to invest in high-quality adhesive paper that is resistant to scratches, moisture, and other damage.

Another consideration is surface preparation. For optimal results, surfaces must be clean, smooth, and properly primed. Any imperfections can lead to bubbles or peeling, which detracts from the overall finish and professional appearance of the product. This additional requirement can add complexity to the manufacturing process, underscoring the need for proper training and skilled workers.

Innovations and Future Directions

The future of adhesive paper in furniture manufacturing looks bright. As technology advances, we are likely to see the development of even more durable, eco-friendly, and visually stunning adhesive papers. Innovations such as digital printing on adhesive paper could further enhance customization options, allowing manufacturers to produce one-of-a-kind pieces for clients.

Furthermore, the integration of augmented reality (AR) and virtual reality (VR) technologies may provide new avenues for designers to visualize how different adhesive papers will look on their furniture, leading to more informed design choices and improved customer satisfaction.

Conclusion

Adhesive paper represents a significant leap forward in the furniture manufacturing sector. Its cost-effectiveness, versatility, and aesthetic potential make it an invaluable tool in the pursuit of innovative furniture design. While challenges remain, the ongoing advancements in adhesive technology promise to enhance its applications, making it a staple in the industry for years to come. As manufacturers increasingly prioritize sustainability and consumer demands for bespoke designs, adhesive paper will undoubtedly play a pivotal role in shaping the future of furniture manufacturing.

Latest news

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025