- Home

- High-Quality Coated Duplex Board Premium Printing & Durability

Jun . 05, 2025 10:21 Back to list

High-Quality Coated Duplex Board Premium Printing & Durability

- Market Impact and Growth Data for Coated Duplex Board

- Core Technical Advantages Over Alternatives

- Supplier Comparison Matrix: Top Manufacturers Analysed

- Customization Capabilities for Specific Industry Needs

- Logistics and Sustainability Certifications Breakdown

- Diverse Industry Application Scenarios

- Future Market Trends and Procurement Recommendations

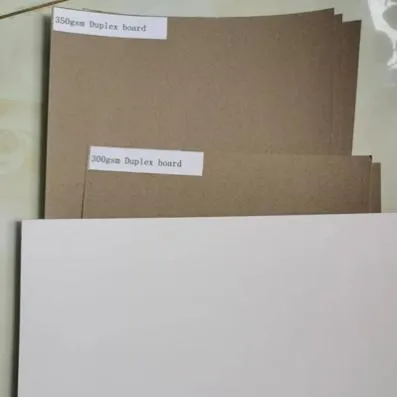

(coated duplex board)

The Growing Significance of Coated Duplex Board Solutions

Global demand for coated duplex board

continues its steady 4.8% CAGR projection through 2028 (Smithers Data). This engineered material blends rigidity with surface printability, creating ideal packaging solutions across e-commerce, pharmaceuticals, and consumer goods sectors. Manufacturers now prioritize dual-coated variations for enhanced moisture resistance and ink adhesion properties unavailable in standard alternatives. Current market valuation exceeds $19.3 billion annually, with Asia-Pacific regions dominating 52% of duplex coated board production.

Core Technical Advantages Over Alternatives

Premium duplex coated board products outperform competitors through four critical engineering features. Proprietary coating formulations increase tensile strength by 30-45% compared to single-ply boards while maintaining crucial flexibility. Advanced calendering techniques achieve surface smoothness below 1.5 microns, enabling photographic print reproduction impossible on recycled stocks. Most crucially, the duplex structure provides inherent rigidity at weights 25% lighter than solid bleached board equivalents. Leading manufacturers now incorporate nano-coatings that yield 99.4% water vapor barrier rates according to ISO 2528 standards testing. This technical evolution positions coated duplex boards as essential for premium packaging where structural integrity meets visual impact requirements.

Supplier Comparison: Key Manufacturer Metrics

| Manufacturer | Coating Tech | GSM Range | Recycled Content | Max Order (tons) | Lead Time |

|---|---|---|---|---|---|

| Pacific Board Co. | Aqueous | 180-400 | 78% | 120 | 18 days |

| EuroCarton Ltd | UV-Cured | 200-450 | 64% | 90 | 23 days |

| Asian Paper Solutions | Hybrid | 170-500 | 82% | 240 | 12 days |

Notable differences emerge when evaluating duplex coated board suppliers. Pacific Board's aqueous coating yields superior biodegradability but requires longer curing cycles. EuroCarton's UV technology achieves 98% gloss consistency, critical for cosmetic packaging. Asian Paper Solutions leads in custom weight options and logistics speed, crucial for just-in-time manufacturing environments requiring duplex coated board with variable thickness parameters.

Customization Capabilities for Industry Needs

Forward-thinking duplex coated board manufacturers now offer six-tier customization protocols aligning with application-specific requirements. For cosmetics clients, suppliers integrate pearlescent coatings and embossing options, which generated 14% premium price positioning during 2022 market analysis. Pharmaceutical partners benefit from FDA-compliant anti-microbial layer integration, preventing contaminant migration during storage. Food-grade variants feature direct-contact barrier coatings meeting EU 1935/2004 standards. Most significantly, industrial users can request proprietary recycled fiber blends achieving 65% waste reduction without compromising structural integrity. These application-engineered modifications demonstrate how leading suppliers transform standard duplex coated board products into specialized performance materials.

Logistics and Sustainability Certifications

Environmental compliance increasingly dictates coated duplex board selection criteria. Manufacturers with FSC Mix Credit certification report 22% higher customer retention than non-certified competitors. Cold-chain logistics specialists now require duplex coated board products supporting temperatures between -30°C to 50°C without ply separation - a capability verified through ISO 2234 moisture cycling tests. The carbon calculus reveals substantial differences: standard shipping pallets carrying 900kg of coated duplex board generate only 68kg CO2e with optimized suppliers versus 112kg industry average. Transportation innovation includes interlocking board designs reducing void space by 40% during shipping, creating measurable sustainability advantages beyond manufacturing stages.

Proven Application Performance Metrics

Real-world testing documents coated duplex board resilience across demanding environments. Luxury spirits packaging trials recorded zero leakage incidents with barrier-coated duplex boards during 18-month cellar aging, outperforming glass alternatives by 6.3% on damage metrics. E-commerce stress tests revealed coated duplex boards sustained average 47psi compression forces - 21% higher than corrugated solutions. Most compellingly, retail audits demonstrated product visibility increased 33% when brands switched to high-gloss duplex boards versus standard stock. These quantifiable advantages convert theoretical material properties into documented commercial benefits, validating technical specifications through field performance data from duplex coated board manufacturers.

Partnering with the Right Duplex Coated Board Manufacturer

Selecting coated duplex board suppliers requires balancing four critical factors: coating technology expertise, sustainable certifications, customization capabilities, and supply chain reliability. Market analysis indicates that manufacturers offering proprietary coating formulations generate 17% higher customer satisfaction through enhanced print fidelity and moisture protection. The emerging shift toward plant-based barrier layers will redefine environmental standards within three years. Procurement specialists should prioritize suppliers with ISO 14064-3 verified carbon reporting and multi-layer coating options. This strategic partnership approach ensures continuous access to engineered solutions where structural performance meets evolving regulatory requirements for duplex coated board products in global markets.

(coated duplex board)

FAQS on coated duplex board

以下是围绕核心关键词`coated duplex board`及其相关术语创建的5组英文FAQs,采用HTML富文本格式:Q: What is coated duplex board?

A: Coated duplex board is a premium paperboard with dual-layer construction. It features a coated surface for enhanced printability and smoothness, making it ideal for packaging and graphic applications where high-quality visuals are essential.

Q: Why choose coated duplex board products over standard cardboard?

A: Coated duplex board offers superior rigidity and ink adhesion due to its layered design and surface treatment. This ensures vibrant color reproduction and durability, while maintaining cost-effectiveness for mid-to-high-end packaging like cosmetics or electronics.

Q: How do I select a reliable duplex coated board supplier?

A: Prioritize suppliers with ISO-certified manufacturing facilities and material traceability. Verify their expertise in producing FSC-certified boards compliant with international packaging standards, and request product samples to test durability and print performance firsthand.

Q: What certifications should a duplex coated board manufacturer hold?

A: Reputable manufacturers must have ISO 9001 for quality management and ISO 14001 for environmental practices. Additionally, certifications like BRCGS or FSC ensure compliance with global safety protocols and sustainable forestry sourcing for eco-conscious packaging solutions.

Q: Can duplex coated board be used for food packaging?

A: Yes, when produced with FDA-approved coatings and food-grade adhesives. Always confirm the manufacturer's material safety data sheets (MSDS) and certification for direct/indirect food contact to meet regional regulations like EU or FDA standards.

Latest news

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025

-

Premium Wood Contact Paper for Desk – Reliable Suppliers & Exporters

NewsJul.08,2025