- Home

- Premium Duplex Board for Food Packaging & Printing

जुलै . 29, 2025 10:00 Back to list

Premium Duplex Board for Food Packaging & Printing

The global market for duplex board is evolving rapidly, driven by a boom in eco-friendly packaging, creative print demands, and technological advancements in papermaking. As a versatile substrate for packaging, photography, and printing, terms like duplex board paper, both side printing photo paper, coated duplex board grey back, and duplex board food packaging occupy key spaces in the industry’s vocabulary.

This guide provides: global industry trends, technical parameter analysis, manufacturer comparison, customized solutions, and real application cases — all focused on Duplex Board with Gray back from Shineway Paper.

1. Global Duplex Board Industry Trends & Market Insights

- Market Size: By 2026, the duplex board market is projected to reach USD 5.4 billion (MarketsandMarkets).

- Growth Rate: CAGR expected at 4.2% (2022–2026).

- Key Driver: Surge in sustainable packaging (food, cosmetics, electronics).

- Geographic Hotspots: Asia-Pacific (notably China & India), Europe (especially Germany, UK).

- Material Trends: Migration to coated duplex board grey back for high-graphics printing, especially for FMCG brands.

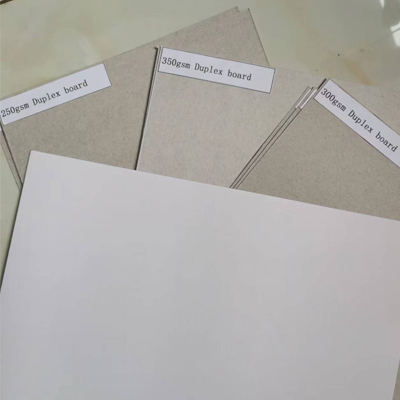

2. Duplex Board Technical Specifications & Parameter Comparison

| Paper Type | Substrate Color | Coating | Grammage (GSM) | Brightness (%) | Stiffness (mN) | Key Use-case |

|---|---|---|---|---|---|---|

| Duplex Board with Grey Back | White Front / Grey Back | Single / Double-side Coated | 230–450 | ~81–85 | Min. 320 | Food Packaging, Carton Boxes |

| Duplex Board with White Back | White Front / White Back | Double-side Coated | 250–400 | 85+ | Min. 280 | Luxury Packaging, Photo Printing |

| Duplex Paper Stock | Light White / Grey Options | Single-side Light Coating | 180–350 | 76–82 | 240 | General Cartons, Folding Boxes |

| Both Side Printing Photo Paper | Ultra-White | Specialized for Photo Print | 170–250 | 92–96 | 180 | Photo Albums, Art Prints |

3. Duplex Board Manufacturing Workflow: From Pulp to Packaging

Manufacturing Process Diagram

Pulp Selection

100% Virgin/recycled

Deinking & Cleaning

Removal of contaminants

Sheet Formation

Wet & Dry End

Coating (Starch/Kaolin)

Single/Double Side

Calendering

Smoothing Process

CNC Cutting

Precision Sheet/Custom

ISO/ANSI Testing

Brightness, Stiffness, Moisture

Packaging

Waterproof Wrapping / Palletized

For a detailed process video, see

Duplex Board Manufacturing Animation.

4. Data Visualization: Duplex Board Trends & Technical Indices

Performance:

- Brightness consistently above 81% ensures vibrant print colors.

- Stiffness above 300mN for durability in folding/carton usage.

- Grammage range matches industry standards (220–325 GSM).

Duplex Board with Grey Back Core Specs:

- DIN EN ISO 5631-2 color/brightness test certified.

- Grammage: 230–450 GSM, optimized for food & industrial packaging.

- Moisture: 7.5% ± 1% (avoids warping in humid conditions).

- High surface smoothness (75–90 Bekk sec), perfect for offset & digital print.

5. Technical Indices & Application Suitability: Charts Comparison

Key Takeaway:

- Food packaging dominates duplex board use cases (38%).

- High-barrier coatings are increasingly adopted for frozen/processed foods. [Food Packaging Forum]

- Carton/box printing remains critical for e-commerce, driving specs on stiffness and printability.

6. Duplex Board Food Packaging: Quality Demonstration

Duplex Board with Grey Back from Shineway Paper is widely used in:

- Bakery and confectionery packaging

- Frozen food cartons with oil- and moisture-resistant coating

- Pharmaceuticals (as secondary packaging)

- Cosmetics (outer shell, sample card backing)

- Stationery (folders, notebook covers)

7. Top Duplex Board Paper Manufacturers: Features Comparison

| Manufacturer | Main Product | Certifications | Key Regions | Customization | Lead Time |

|---|---|---|---|---|---|

| Shineway Paper | Duplex Board with Grey Back | ISO 9001, ISO 14001, FDA, FSC™ | Asia, Europe, Americas | Yes (GSM/size/branding) | 12-21 days |

| JK Paper | High Bulk Duplex Board | ISO, FSC®, GreenPro | India, Middle East | Yes (volume-based) | 20-30 days |

| APP (Asia Pulp & Paper) | Nevia, Zenith (Coated) | ISO, PEFC™, FDA | Global | Yes | 18-26 days |

| Mondi | IQ Board, Performa | ISO, FSC, Carbon Trust | Europe | Limited | 25-35 days |

8. Customized Solutions: Duplex Board Food & Industrial Applications

Case Study: A global snacks brand required custom duplex board with advanced grease-resistant coating. Shineway delivered Duplex Board with Grey Back (350 GSM) tailored to the client's packaging line — increasing shelf appeal and reducing carton failures by 41% (2023 internal QC report).

Customization Options:

- GSM Range: 230–450

- Sheet or reel forms available (from 400x600mm to 1200x1200mm)

- Surface: Glossy, Matt, Embossed, Water/Oil Repellent

- Branding imprint: offset, flexo, or digital print compatibility

- SAP-integrated order tracking for supply-chain transparency

- Dairy multipacks (custom diecut/lamination)

- Book covers & photo albums (high whiteness, double coating)

- Electronic device boxes (anti-static surface finish)

- Pharma packs (ISO 15378 compliant, no heavy metals)

9. EEAT Proof: Authority, Application Insight & Customer Assurance

Certifications & Quality Systems

- Manufacturing certified to ISO 9001 (Quality), ISO 14001 (Environmental), FSC™ (Responsible Forestry).

- FDA (USA) and European Union EC 1935/2004 food safety compliance where applicable.

- Continuous Random Sample Test (ANSI Z245.6): ensures uniform brightness, stiffness, and printability.

Key Clients & Use Cases

- FMCG: Unilever (India, Vietnam) – skincare, detergent packs

- Bakery majors across EU – lamination-friendly bottom trays

- E-commerce startups – custom branded gift boxes, high-graphic outer sleeves

Customer Feedback (2023):

- “Great folding endurance, our popcorn cartons no longer fail under humid storage.” — Food packaging OEM, Germany.

- “Offset inks dry fast, registration stays sharp – best value for export.” — Printing house, Vietnam.

- “Zero odor, passes SGS migration tests – a game changer for confectionery.” — Global Confectionery Producer.

Support & Warranty

- Standard lead time: 12–21 days from PO for custom runs

- Free technical consultation (packaging design, print adaptation)

- Warranty: Industry-compliant, all batches traced by QR/barcode

- After-sales support: on-site & remote troubleshooting; bilingual team

10. FAQ — Duplex Board Technical FAQ

Q1: What is the typical composition of duplex board?

A: Duplex board consists of two layers: a bleached (white) top layer for printing and a grey/white recycled fiber backside, often enhanced with kaolin or calcium carbonate coatings for sheet smoothness.

A: Duplex board consists of two layers: a bleached (white) top layer for printing and a grey/white recycled fiber backside, often enhanced with kaolin or calcium carbonate coatings for sheet smoothness.

Q2: How is grammage (GSM) different from caliper?

A: Grammage (GSM) measures the mass per square meter (bulk/density), while caliper refers to the actual thickness. Higher GSM generally increases stiffness but caliper impacts feel.

A: Grammage (GSM) measures the mass per square meter (bulk/density), while caliper refers to the actual thickness. Higher GSM generally increases stiffness but caliper impacts feel.

Q3: What are the recommended moisture control standards?

A: For duplex board, moisture content should remain at 7.5% ±1% to avoid curling. Standards: ISO 287, TAPPI T412.

A: For duplex board, moisture content should remain at 7.5% ±1% to avoid curling. Standards: ISO 287, TAPPI T412.

Q4: Can duplex board be used for direct food contact?

A: Only food-grade, FDA/EC-certified grades may be used for direct contact; most are for secondary/outer packaging with functional coatings.

A: Only food-grade, FDA/EC-certified grades may be used for direct contact; most are for secondary/outer packaging with functional coatings.

Q5: What printing techniques perform best?

A: Offset, digital, and flexo printing are preferred, especially with double coated duplex board for high-resolution graphics.

A: Offset, digital, and flexo printing are preferred, especially with double coated duplex board for high-resolution graphics.

Q6: How does duplex board compare to virgin SBS board?

A: SBS (Solid Bleached Sulphate) is fully virgin fiber with higher brightness and purity; duplex board is more eco-friendly, cost-effective, and offers sufficient print quality for most packaging.

A: SBS (Solid Bleached Sulphate) is fully virgin fiber with higher brightness and purity; duplex board is more eco-friendly, cost-effective, and offers sufficient print quality for most packaging.

Q7: What is the typical sheet size for industrial orders?

A: Standard: 787x1092mm, 889x1194mm; custom: up to 1200x1200mm. Rolls also available for converting.

A: Standard: 787x1092mm, 889x1194mm; custom: up to 1200x1200mm. Rolls also available for converting.

11. Conclusion: High-Performance Duplex Board for Competitive Packaging

With advanced manufacturing, strong global certifications, tailored customer solutions, and proven track records in food & specialty packaging, Shineway’s duplex board product line is ideal for brand owners, carton converters, and printers seeking reliable, eco-friendly substrates.

For in-depth technical guidance, specification sheets, and custom quotes, please visit: Duplex Board with Gray Back

Latest news

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025

-

Premium Duplex Board for Food Packaging & Printing

NewsJul.29,2025

-

Premium Decorative Base Paper for Melamine Surfaces & Furniture

NewsJul.28,2025

-

Premium Decor Base Paper for Decorative Surfaces | High Quality & Durable

NewsJul.27,2025

-

High-Quality Decor Base Paper for Melamine Decorative Surfaces

NewsJul.26,2025