- Home

- Top Quality Duplex Coated Board Production from Leading Manufacturers in the Industry

നവം . 28, 2024 03:57 Back to list

Top Quality Duplex Coated Board Production from Leading Manufacturers in the Industry

Understanding Duplex Coated Board Manufacturing A Comprehensive Overview

Duplex coated board is an essential material in the packaging and printing industries, renowned for its high-quality surface and excellent performance characteristics. This type of board, primarily made from recycled paper, has gained popularity thanks to its eco-friendly nature and versatility. As the demand for sustainable and efficient packaging solutions continues to rise, manufacturers of duplex coated board are vital players in the market.

What is Duplex Coated Board?

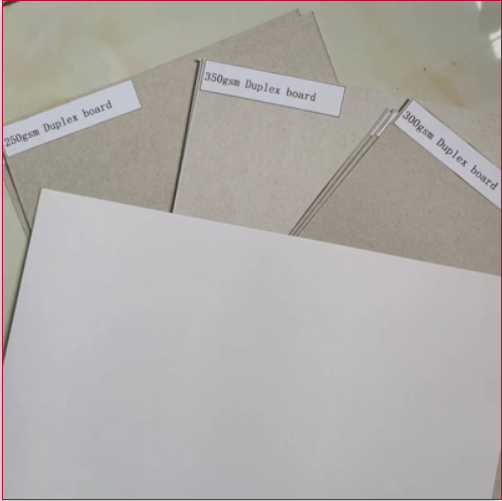

Duplex coated board is a type of paperboard that is coated on one or both sides to enhance its appearance and functionality. The coating typically comprises a mixture of clay and other additives, resulting in a smooth, high-shine surface that is ideal for printing. The board is available in various thicknesses and weights, making it suitable for a wide range of applications, from lightweight packaging to rigid boxes and displays.

The two most common types of duplex boards are the white back duplex and the grey back duplex. The white back duplex has a white coating on one side, making it perfect for high-quality printing, while the grey back duplex features a more cost-effective solution with a grey exterior that is less visually appealing but maintains its durability and functionality.

Manufacturing Process

The manufacturing process of duplex coated board involves several key stages that ensure the final product meets industry standards for quality and sustainability. The process begins with the sourcing of raw materials, primarily recycled paper pulp, which is then processed and cleaned to remove impurities.

Once the pulp is prepared, it is fed into a machine called a paper sheet former, where it is transformed into sheets. This is followed by the drying process, where excess moisture is removed to ensure a sturdy base is formed. After drying, the sheets proceed to the coating stage. Here, a mixture of clay and other compounds is applied to enhance the surface properties of the board. This coating not only improves printability but also adds resistance to moisture, making it more suitable for packaging applications.

The next step is the calendering process, where the coated sheets are passed through a series of rollers to achieve the desired thickness and smoothness. This is a critical step as it affects the final appearance and print quality of the board. Finally, the sheets are cut, packed, and prepared for distribution.

duplex coated board manufacturer

Quality Assurance

The quality assurance process in duplex coated board manufacturing is rigorous. Manufacturers implement a series of tests to ensure the board meets the necessary specifications for strength, printability, and surface quality. These tests often include checks for dimensional stability, whiteness, and smoothness, ensuring that the product can withstand the rigors of printing and packaging without compromising its integrity.

Market Applications

Duplex coated board is utilized in an array of applications due to its flexibility and quality. In the packaging sector, it is commonly used for food packaging, luxury boxes, and retail displays. The printability and aesthetic qualities of the board make it a favorite among businesses seeking to enhance their branding through packaging.

Moreover, it is increasingly used in the production of graphics, posters, and promotional materials. The ability to hold vivid colors and detail makes duplex coated board an ideal choice for companies wishing to create impactful visual presentations.

Sustainability Considerations

As environmental consciousness grows, manufacturers are focusing on sustainable practices in duplex coated board production. Many are utilizing recycled materials and implementing processes that reduce waste and energy consumption. Additionally, by producing boards that are recyclable, manufacturers are contributing to a circular economy and reducing the overall carbon footprint associated with production and disposal.

Conclusion

Duplex coated board manufacturers play a crucial role in meeting the needs of various industries focusing on quality, sustainability, and versatility. As the market evolves and consumer preferences shift towards eco-friendly solutions, the importance of this material will only continue to grow, leading to innovative manufacturing processes and products that align with sustainable practices. Through commitment to excellence and environmental responsibility, duplex coated board manufacturers are setting a standard for the future of packaging and printing solutions.

Latest news

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025

-

Premium Contact Paper for Table Top - Durable, Easy to Apply, Stylish Surfaces

NewsJun.10,2025

-

Contact Paper to Cover Dresser Durable & Easy Application

NewsJun.10,2025

-

Top Dresser Drawer Contact Paper Suppliers Waterproof & Durable Liner

NewsJun.10,2025

-

Premium Desk Wall Paper Suppliers Export & Manufacture

NewsJun.09,2025

-

Durable Contact Paper for Bookcase - Easy Apply & Stylish Protection

NewsJun.09,2025