- Home

- Exploring Sustainable Furniture Solutions Through OEM Partnerships and Innovations

Aug . 17, 2024 12:40 Back to list

Exploring Sustainable Furniture Solutions Through OEM Partnerships and Innovations

Understanding OEM in the Furniture Industry

In today's globalized economy, Original Equipment Manufacturing (OEM) has become a significant driver of business, especially in the furniture industry. This concept refers to companies that design and manufacture products that are marketed under another company's brand. The OEM model plays a critical role in reshaping how furniture is designed, produced, and distributed worldwide.

The Rise of OEM in Furniture Production

The furniture industry has witnessed a substantial shift towards OEM practices in recent years. Many furniture brands now outsource their manufacturing to OEM partners, which allows them to focus on branding, marketing, and sales while leveraging the manufacturing expertise and cost advantages offered by specialized producers. This transition has enabled smaller companies to compete in the marketplace without the high overhead costs associated with owning and operating factories.

One of the main benefits of OEM partnerships is cost efficiency. By outsourcing production, brands can reduce their capital expenditure on machinery, labor, and materials. This is particularly advantageous in an industry where profit margins can be slim. OEM manufacturers often benefit from economies of scale, allowing them to produce high-quality furniture at lower prices, which are then passed on to the brands they supply.

Quality Control and Innovation

Quality control is vital in the OEM process. Brands that rely on third-party manufacturers must ensure that their partners adhere to the same quality standards they set for their own products. This necessitates a strong relationship and communication between the brand and the OEM to guarantee that the final product meets the desired specifications.

Additionally, OEM manufacturing can foster innovation in furniture design. Many OEMs have access to cutting-edge technologies and materials, allowing them to experiment with new designs and functionalities that may not be feasible for a brand to produce in-house. This collaboration can lead to unique and innovative products that capture consumers’ attention and drive sales.

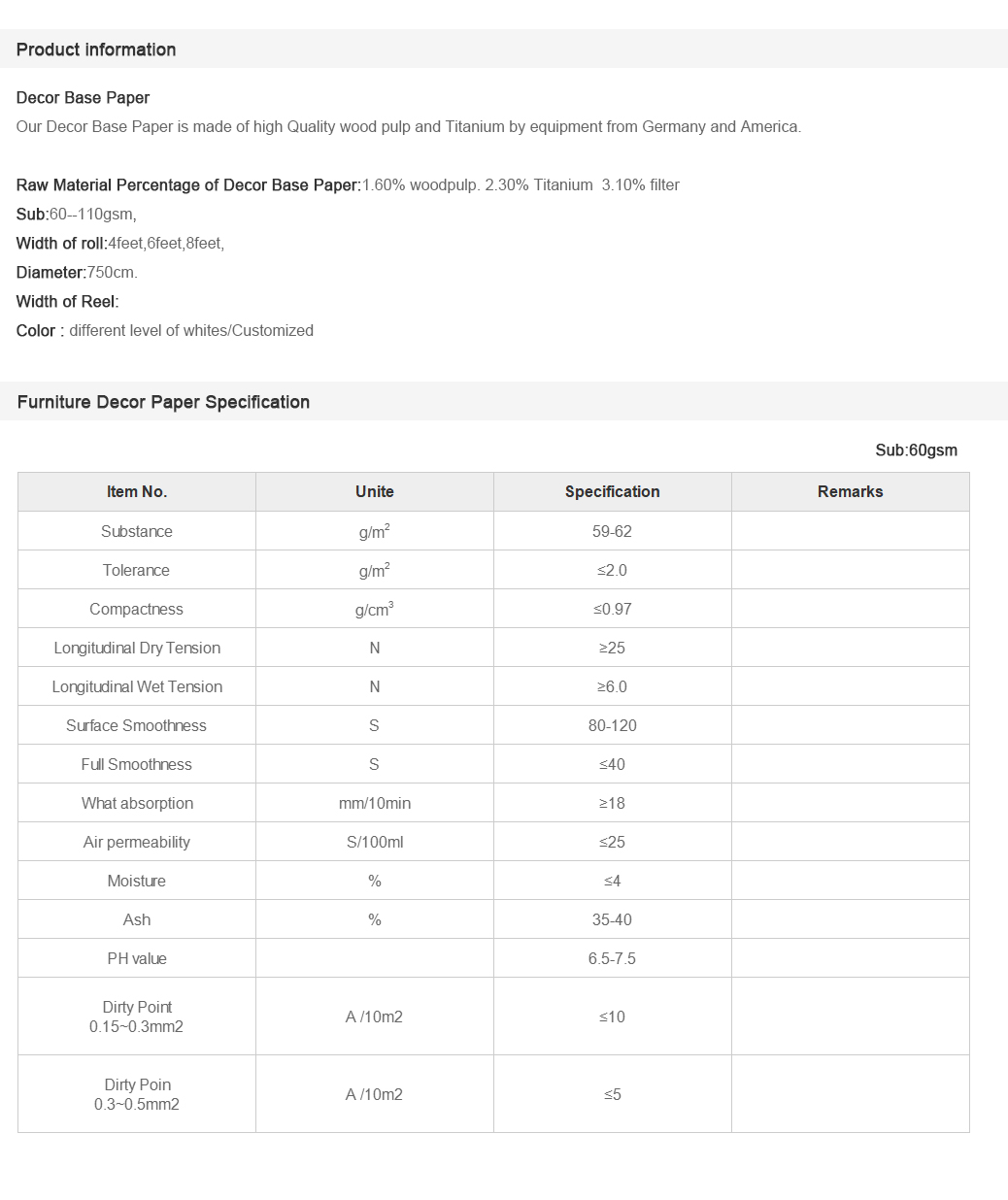

oem paper on furniture

Environmental Considerations

As sustainability becomes an increasingly important concern for consumers, the dialogue around OEM manufacturing in the furniture industry also shifts. Many OEM manufacturers are adopting eco-friendly practices by using sustainable materials and reducing waste. Brands leveraging these OEM partners can enhance their own sustainability credentials while meeting the rising consumer demand for environmentally responsible products.

Furthermore, OEM partnerships are often global in nature, which can translate to varying impacts on the environment depending on the location of manufacturing. As brands strive to maintain lower carbon footprints, they are increasingly seeking OEM partners that prioritize sustainability in their production processes, thereby aligning with consumers’ values.

Challenges of OEM Agreements

Despite its numerous advantages, the OEM model does not come without challenges. Intellectual property concerns can arise, particularly when proprietary designs or technologies are shared with a manufacturer. Brands must establish clear contractual agreements to protect their designs and ideas.

Moreover, reliance on OEM partners can sometimes lead to supply chain vulnerabilities. Political instability, natural disasters, or unforeseen events, such as a pandemic, can disrupt manufacturing processes and impact product availability. Thus, brands need to consider strategies for risk management and diversification of their manufacturing sources.

Conclusion

In conclusion, OEM manufacturing has revolutionized the furniture industry by enabling brands to offer high-quality, innovative products at competitive prices. While it brings significant benefits in terms of cost efficiency, design flexibility, and sustainability, it also poses challenges that must be carefully managed. As the global furniture market continues to evolve, the OEM model will likely remain an integral component of how furniture is produced and marketed in the years to come. By maintaining strong partnerships and prioritizing quality control, brands can harness the advantages of OEM manufacturing while mitigating potential risks, ensuring their continued success in a dynamic market.

Latest news

-

Premium Contact Paper Over Desk – Durable & Stylish Desk Cover Solutions

NewsJul.05,2025

-

High-Quality Duplex Board Food Packaging - Reliable Suppliers & Exporters

NewsJul.05,2025

-

Duplex Paper Rate Per Kg – Best Manufacturer & Supplier Prices Online

NewsJul.04,2025

-

High-Quality Duplex Kraft Paper Reliable Suppliers & Exporters Top Manufacturers

NewsJul.04,2025

-

Removable Contact Paper for Kitchen Cabinets - Durable, Easy to Install, Stylish Designs

NewsJun.24,2025

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025