- Namai

- Understanding the Duplex Board: Manufacturing Process, Uses, and Specifications

Bal . 03, 2024 11:25 Grįžti į sąrašą

Understanding the Duplex Board: Manufacturing Process, Uses, and Specifications

what is duplex board?Duplex board, a versatile type of duplex cardboard, has garnered widespread popularity across various industries due to its durability, versatility, and cost-effectiveness. From packaging to printing, understanding the manufacturing process, uses, and specifications of duplex board is essential for businesses and consumers alike.

Duplex Board Manufacturing Process

The manufacturing process of duplex board involves several stages to ensure the production of high-quality paperboard. It typically begins with the pulping of wood fibers, which are then refined and blended with other additives such as chemicals and pigments. The resulting pulp is then formed into sheets through a papermaking machine. In the case of duplex board, two layers of paper are bonded together to create a thicker and sturdier board. This bonding process can involve the use of adhesive or lamination techniques. Once formed, the duplex board undergoes various treatments such as coating, calendaring, and finishing to enhance its surface properties and printability.

Dvipusės plokštės naudojimas

Duplex board finds applications across a wide range of industries due to its versatility and strength. what is duplex board used for?It is commonly used in packaging for products such as food items, cosmetics, pharmaceuticals, and consumer goods. The sturdy nature of duplex board makes it ideal for packaging materials that require protection during transportation and handling. Additionally, duplex board is widely used in printing for applications such as posters, brochures, book covers, and packaging inserts. Its smooth surface and excellent printability ensure vibrant and crisp printing results, making it a preferred choice for graphic materials.

Duplex Board Specification

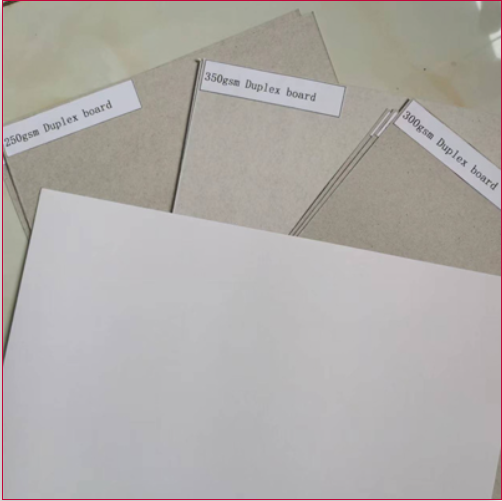

Duplex board is available in various specifications to meet the diverse needs of different applications. Specifications include factors such as weight, thickness, coating, and surface finish. The weight of duplex board is measured in grams per square meter (gsm), with common weights ranging from 200 gsm to 500 gsm. Thickness can vary depending on the specific requirements of the application, with options for single-ply or multi-ply boards. Coating options include matte, glossy, or satin finishes, depending on the desired aesthetic and functional properties.

Duplex Paper Rate

The rate of duplex paper can vary depending on factors such as quality, specifications, and market demand. Prices may fluctuate based on raw material costs, manufacturing expenses, and economic conditions. Generally, dvipusių plokščių tiekėjai offer a cost-effective solution compared to other types of paperboard, making it a popular choice for various applications.

Duplex board is a versatile and durable paperboard used across a wide range of industries for packaging and printing applications. Understanding its manufacturing process, uses and duplex board specifications, and rates is essential for making informed decisions in selecting the right duplex board for specific needs. Whether it's for packaging fragile goods or printing promotional materials, duplex board continues to be a reliable and cost-effective solution for businesses worldwide. If you want to know more about duplex board price,please contact us.

Naujausios naujienos

-

White Contact Paper for Cabinets – Transform Your Kitchen

žiniosJun.13,2025

-

Duplex Board Paper: Properties and Manufacturing Process

žiniosJun.13,2025

-

Food Packaging Solutions: Why Duplex Board is a Top Choice

žiniosJun.13,2025

-

Best Types of Furniture Decoration Paper

žiniosJun.13,2025

-

What Are the Best Adhesives for Applying Furniture Decoration Paper?

žiniosJun.09,2025

-

Key Properties and Uses of Duplex Board Paper in Packaging

žiniosJun.09,2025