- Home

- coated duplex board grey back

Jan . 22, 2025 02:51 Back to list

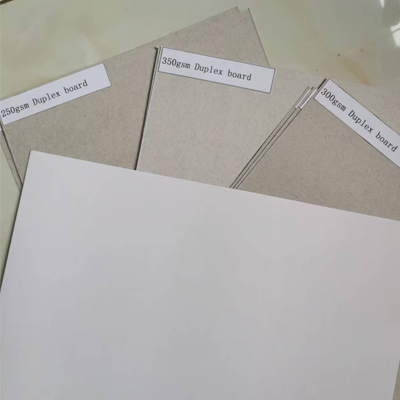

coated duplex board grey back

The art of high-quality duplex board manufacturing is a precise and sophisticated process that few can master, distinguishing those in the field who are dedicated to excellence. Within the realm of paper and board products, duplex boards occupy a niche, catering to specific market needs such as packaging and retail display materials. Stemming from years of innovation and adherence to rigorous standards, producing a high-quality duplex board is not merely an industrial operation but a culmination of science, expertise, and craftsmanship.

Post-drying, the coating process presents another layer of complexity, where the board is given its final finish. Depending on the intended use, different coatings may be applied, from glossy appearances for high-end packaging to matte finishes for general use. Expertise in the application of coatings is essential to avoid defects such as streaking or uneven surfaces, which can compromise the board's aesthetic and functional qualities. The role of chemical engineers and material scientists is crucial here, as they develop specialized coatings that enhance the board’s brightness, printability, and moisture resistance. Finally, quality control is the decisive factor that sets high-quality duplex board manufacturers apart. Throughout the production line, boards are subjected to rigorous testing, including tensile strength, opacity, grammage, and color consistency. This step validates the board's quality, ensuring it meets the necessary international standards. Quality assurance specialists with a keen eye for detail are essential, providing the certitude that each batch of produced boards meets the high expectations set by the industry and clients alike. The authority of a manufacturer in the realm of duplex board production is often established through certifications and compliance with international standards such as ISO and FSC. These credentials endorse the trustworthiness of a manufacturer, highlighting their commitment to environmental sustainability, product quality, and operational excellence. Companies that emphasize transparent sourcing, ethical production methods, and consistent quality assurance practices are regarded as leaders in this domain. Navigating the intricacies of duplex board manufacturing demands expertise across several domains, including material science, engineering, and quality management. It is this blend of experience, precision, and unwavering commitment to quality that propels manufacturers to the forefront of the industry. Companies that succeed in producing high-quality duplex boards not only contribute significantly to their clients' success but also set a standard of environmental and operational excellence. They are innovators who continually refine their processes to meet the evolving demands of the market, offering products that are not only functional but also embodying the highest standards of sustainability and quality.

Post-drying, the coating process presents another layer of complexity, where the board is given its final finish. Depending on the intended use, different coatings may be applied, from glossy appearances for high-end packaging to matte finishes for general use. Expertise in the application of coatings is essential to avoid defects such as streaking or uneven surfaces, which can compromise the board's aesthetic and functional qualities. The role of chemical engineers and material scientists is crucial here, as they develop specialized coatings that enhance the board’s brightness, printability, and moisture resistance. Finally, quality control is the decisive factor that sets high-quality duplex board manufacturers apart. Throughout the production line, boards are subjected to rigorous testing, including tensile strength, opacity, grammage, and color consistency. This step validates the board's quality, ensuring it meets the necessary international standards. Quality assurance specialists with a keen eye for detail are essential, providing the certitude that each batch of produced boards meets the high expectations set by the industry and clients alike. The authority of a manufacturer in the realm of duplex board production is often established through certifications and compliance with international standards such as ISO and FSC. These credentials endorse the trustworthiness of a manufacturer, highlighting their commitment to environmental sustainability, product quality, and operational excellence. Companies that emphasize transparent sourcing, ethical production methods, and consistent quality assurance practices are regarded as leaders in this domain. Navigating the intricacies of duplex board manufacturing demands expertise across several domains, including material science, engineering, and quality management. It is this blend of experience, precision, and unwavering commitment to quality that propels manufacturers to the forefront of the industry. Companies that succeed in producing high-quality duplex boards not only contribute significantly to their clients' success but also set a standard of environmental and operational excellence. They are innovators who continually refine their processes to meet the evolving demands of the market, offering products that are not only functional but also embodying the highest standards of sustainability and quality.

Latest news

-

Premium Decor Base Paper for Laminates & Furniture

NewsAug.13,2025

-

Premium Decor Base Paper for Durable Laminate Surfaces

NewsAug.12,2025

-

Premium Furniture Decoration Paper | Melamine & Self-Adhesive

NewsAug.11,2025

-

Coated Duplex Board Paper: Grey Back & Double Sided Printing

NewsAug.10,2025

-

Self-Adhesive Paper for Wood Furniture | Easy Peel & Stick Decor

NewsAug.09,2025

-

Premium Duplex Board Paper: Coated Grey & White Back

NewsAug.08,2025