- Home

- coated duplex board grey back manufacturers

ធ្នូ . 10, 2024 06:48 Back to list

coated duplex board grey back manufacturers

Coated Duplex Board Grey Back Manufacturers A Comprehensive Overview

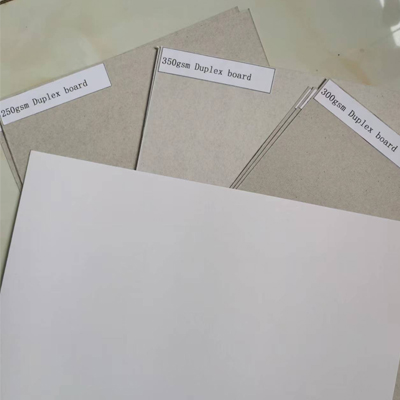

Coated duplex board, particularly with a grey back, has become an essential material in various industries, including packaging, printing, and graphic arts. This type of paperboard combines the desirable qualities of strength, lightweight, and versatility, making it a preferred choice among manufacturers and consumers alike. In this article, we will explore the key features, manufacturing process, applications, and the leading manufacturers in the coated duplex board grey back market.

Key Features of Coated Duplex Board Grey Back

One of the most significant characteristics of coated duplex board is its two-sided structure. The front side is typically coated for high-quality printing, ensuring vibrant colors and crisp images. The grey back, on the other hand, provides several advantages. It offers a sturdy base that enhances durability and prevents light from penetrating, making it ideal for certain packaging solutions. Additionally, the grey back adds to the overall thickness of the board, providing the rigidity needed for various applications.

The coating on the duplex board enhances its surface properties, making it suitable for a variety of printing techniques, including offset, flexographic, and digital printing. This versatility allows manufacturers to produce visually appealing packaging materials, which are essential for branding and marketing.

Manufacturing Process

The manufacturing process of coated duplex board involves several critical steps. First, recycled paper pulp is sourced and processed. This pulp is either derived from post-consumer waste or from virgin fibers. The purity of the pulp plays a crucial role in the quality of the final product.

Once the pulp is ready, it undergoes a refined pulping process to achieve the desired consistency. The pulp is then formed into sheets and subjected to various treatments, including pressing and drying. After the sheets are dried, they are coated to enhance their printability. Common coatings include clay, latex, or starch, which provide smoothness and a glossy finish.

After coating, the sheets are cut into the desired size and packaged for distribution. Quality checks throughout the manufacturing process ensure that the final product meets industry standards and customer specifications. This attention to detail is what sets leading manufacturers apart in the competitive market.

Applications of Coated Duplex Board Grey Back

coated duplex board grey back manufacturers

The applications of coated duplex board grey back are extensive. It is primarily used in the packaging industry for folding cartons, which house everything from food products to electronics. The robust nature of the grey back provides the stability needed to protect the contents while maintaining an appealing exterior.

Additionally, this grade of duplex board is commonly utilized in the printing industry for brochures, flyers, and other marketing materials. The high-quality coated surface ensures that printed materials stand out, effectively conveying a brand’s message.

Other notable applications include

1. Point-of-Sale Displays Coated duplex board is favored in retail settings for creating eye-catching displays that draw customer attention. 2. Stationery Products Products like business cards, letterheads, and other stationeries benefit from the premium finish and durability of duplex board.

3. Book Covers The rigidity of the grey back makes it a popular choice for hardcovers and protective book covers.

Leading Manufacturers of Coated Duplex Board Grey Back

The market for coated duplex board grey back is populated by several prominent manufacturers. Companies like International Paper, WestRock, and Smurfit Kappa are known for their high-quality products and innovative solutions. They often invest in technology and sustainable practices to enhance production efficiency and reduce environmental impact.

Moreover, many manufacturers are focused on research and development to diversify their product offerings, catering to specific industries and evolving consumer demands. This commitment to quality and innovation is crucial as businesses strive for competitive advantage in a saturated market.

Conclusion

Coated duplex board grey back manufacturers play a pivotal role in supplying a versatile and essential product for numerous applications. As industries continue to shift towards sustainability and eco-friendly practices, the coated duplex board market is likely to evolve with these trends. By understanding the features, applications, and key players in this niche, businesses can better position themselves in a dynamic marketplace. Whether for packaging solutions or printing needs, coated duplex board remains a critical component in achieving quality and efficiency.

Latest news

-

High-Quality Furniture Decoration Paper for Stylish Interiors

NewsJul.24,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.23,2025

-

Premium Duplex Board Paper for High Quality Printing & Packaging

NewsJul.22,2025

-

Premium Duplex Board | Food Packaging & Printing Solutions

NewsJul.22,2025

-

65gsm ML1085 Paper Specs: Lightweight & Durable for Printing

NewsJul.20,2025

-

High-Quality Bathroom Cabinet Contact Paper – Durable & Stylish Leading Suppliers, Exporters, Manufacturers

NewsJul.08,2025