- Home

- Duplex Board-Duplex Board Strength

Нау . 13, 2024 09:42 Back to list

Duplex Board-Duplex Board Strength

Introduction

The duplex board is a paperboard made from two layers of kraft paper. It is used in packaging and printing applications for its strength and durability. The duplex board can be made stronger by adding fillers to the paperboard. The most common applications of duplex boards are in the packaging and printing industries.

What is the duplex board?

Types of duplex board

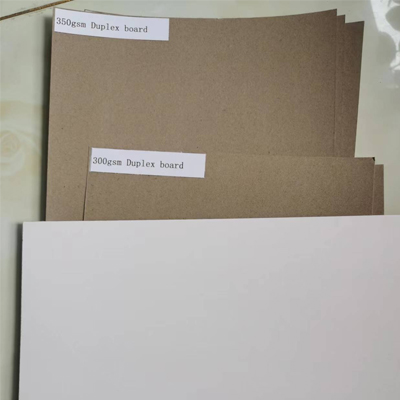

A Duplex board is paperboard made from two layers of paper. The top layer is made from bleached chemical pulp, and the bottom layer is made from recycled paper or virgin kraft paper. Duplex boards can be either white or brown, depending on the type of paper used for the top layer.

There are two types of duplex boards: 1) solid bleached sulfate (SBS) and 2) folding boxboard (FBB). SBS is a high-quality duplex board often used for packaging food and other products that require a clean, white surface. FBB is a lower-quality duplex board often used for packaging products that do not require a clean, white surface.

Benefits of duplex board

Duplex board has several benefits over other types of paperboard:

- It is solid and durable, making it ideal for packaging products that need to be shipped or stored for long periods.

- It is resistant to moisture and humidity, making it ideal for packaging products sensitive to these conditions (such as food).

- It is easy to print on, making it ideal for packaging products that need to have graphic design elements such as logos or images.

- It is recyclable, making it an environmentally friendly option for packaging products.

How is duplex paper made?

Duplex paper is made by bonding two sheets of paper together with an adhesive material such as resin or glue. The top sheet of paper is typically made from bleached chemical pulp, and the bottom sheet is made from recycled paper or virgin kraft paper. The adhesive material bonds the two sheets together so they cannot be separated without damaging the papers.

How strong is the duplex board?

The strength of the duplex board is affected by several factors, such as basis weight, caliper, density, and finish.

Basis weight is paper weight in grams per square meter (gsm). The higher the base weight, the thicker the paper and the stronger it is.

Caliper is the thickness of paper in millimeters (mm). The thicker the paper, the stronger it is.

Density measures how much mass a paper has in a given volume. The higher the density, the more compact the fibers are and the stronger the paper is.

Finish refers to the surface treatment of paper. Coated papers have a smooth finish and are solid and durable. Uncoated papers have a rougher finish and are not as strong or durable.

How to make the duplex board stronger

There are several ways to make the duplex board stronger:

- Use a higher basis weight paper.

- Use thicker caliper paper.

- Use denser paper.

- Use coated paper with a smooth finish.

Applications of the duplex board.

Packaging industry

Duplex board is commonly used in the packaging industry for various applications. It is often used as an outer layer for corrugated boxes, providing strength and rigidity. It can also be used as the linerboard for folding cartons and boxboards. In addition, the duplex board can be die-cut and printed on, making it suitable for use in point-of-purchase displays and other marketing materials.

Printing industry

Duplex board is also widely used in the printing industry due to their excellent printability and smooth surface finish. It is commonly used for book covers, brochures, catalogs, magazines, direct mail, and packaging applications requiring high-quality printing. Additionally, the duplex board can be laminated with other materials to create composite boards with unique properties and performance characteristics.

Other applications

Other typical applications for the duplex board include signboards, display boards, whiteboards, core stock for laminates, and backing for carpets and floor coverings. Additionally, the duplex board can be die-cut into shapes or strips for use in various industrial applications, such as gaskets, seals, washers, and shims.

Why is the duplex board used in packaging?

There are many reasons why the duplex board is used in packaging. One reason is that it provides good protection for the product. Another reason is that it is solid and durable, so it can withstand the rigors of shipping and handling. Additionally, the duplex board is lightweight, which helps keep shipping costs down. And finally, the duplex board is recyclable, making it a sustainable choice for packaging materials.

Conclusion

A Duplex board is a paperboard made from two layers of paper. It is used in packaging and printing applications because of its strength and durability. The strength of duplex boards depends on several factors, including the type of paper used, the manufacturing process, and the way it is used in packaging or printing applications. By understanding how the duplex board is made and how its strength can be affected, businesses can ensure that they are using the best possible material for their needs.

Latest news

-

Premium Duplex Board for AI with GPT-4-Turbo

NewsJul.31,2025

-

Premium Decor Base Paper | Durable & Versatile Prints

NewsJul.31,2025

-

High-Quality Furniture Decoration Paper for Stunning Interiors

NewsJul.30,2025

-

High Quality Duplex Board Paper for Packaging Solutions

NewsJul.30,2025

-

High-Quality Duplex Board Paper for Both Side Printing & Packaging

NewsJul.29,2025

-

High-Quality Decor Base Paper for Laminates & Furniture Surfaces

NewsJul.29,2025