- Home

- Suppliers for Duplex Board Production Process and Manufacturing Techniques

11月 . 30, 2024 02:51 Back to list

Suppliers for Duplex Board Production Process and Manufacturing Techniques

The Duplex Board Manufacturing Process Insights into the Supplier Landscape

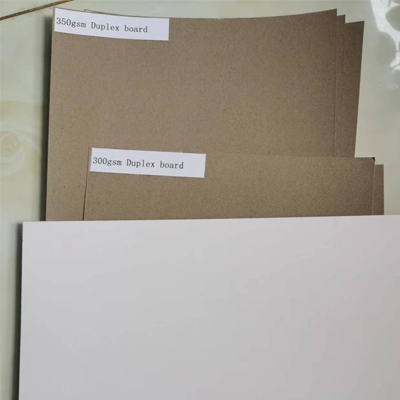

Duplex board, a popular choice in the packaging and printing industries, is celebrated for its strength, lightweight nature, and ease of printability. This versatile material is primarily used in the production of boxes, containers, and various packaging solutions. Understanding the manufacturing process of duplex board and the role of suppliers in this industry can shed light on its significance and applications.

The duplex board manufacturing process typically involves several key stages pulping, refining, forming, pressing, and drying. The first step, pulping, involves breaking down wood chips or recycled paper into cellulose fibers. This process is crucial as it determines the quality and characteristics of the final product. Suppliers often utilize advanced technologies and eco-friendly practices in this stage to ensure sustainability while meeting the increasing demand for duplex board.

Once the pulp is prepared, it goes through the refining process, where the fibers are further processed to enhance their strength and flexibility. This stage is critical as the properties of the duplex board, such as thickness and durability, are influenced by the refining technique employed. Suppliers with extensive expertise in this area can greatly impact the quality of the final board, ensuring that it meets customer specifications.

duplex board manufacturing process supplier

The next phase is forming, where the refined pulp is spread onto a moving screen to drain excess water, creating a continuous sheet. This sheet is then pressed to remove more moisture, followed by the drying process, which solidifies the structure of the duplex board. Throughout these stages, suppliers play a vital role in maintaining quality control to guarantee that the end product is consistent and reliable.

Moreover, the duplex board can be coated or treated with various finishes. Suppliers often provide customization options, allowing clients to choose specific textures or colors to enhance the visual appeal of their products. This flexibility is a significant advantage for businesses seeking unique packaging solutions that stand out in a competitive market.

In the competitive landscape of duplex board suppliers, companies are increasingly focusing on sustainable practices. Many suppliers are adopting recycled materials and environmentally friendly production methods, appealing to consumers who prioritize sustainability in their purchasing decisions. This shift not only benefits the environment but also aligns with the growing trend of corporate social responsibility.

In conclusion, the duplex board manufacturing process involves several intricate steps, each of which is critical to delivering a high-quality product. Suppliers play an essential role in this ecosystem, with their expertise and commitment to sustainability driving the industry forward. As demand continues to grow, understanding the nuances of the manufacturing process and supplier dynamics will be crucial for businesses looking to leverage duplex board in their operations.

Latest news

-

Cupboard Decoration with Paper - Stylish Designs, Custom Sizes & Bulk Supply

NewsJun.10,2025

-

Premium Contact Paper for Table Top - Durable, Easy to Apply, Stylish Surfaces

NewsJun.10,2025

-

Contact Paper to Cover Dresser Durable & Easy Application

NewsJun.10,2025

-

Top Dresser Drawer Contact Paper Suppliers Waterproof & Durable Liner

NewsJun.10,2025

-

Premium Desk Wall Paper Suppliers Export & Manufacture

NewsJun.09,2025

-

Durable Contact Paper for Bookcase - Easy Apply & Stylish Protection

NewsJun.09,2025