- Home

- Coated Duplex Board Grey Back Manufacturer | High-Quality Paper Supplier

Set . 16, 2024 03:38 Back to list

Coated Duplex Board Grey Back Manufacturer | High-Quality Paper Supplier

The Rise of Coated Duplex Board with Grey Back A Manufacturer’s Perspective

In the realm of packaging and printing, coated duplex board with a grey back has emerged as a preferred choice among manufacturers and designers alike. This versatile material offers a unique blend of durability, aesthetic appeal, and cost-effectiveness, making it an essential component in various applications.

Manufacturers of coated duplex board often highlight its unique construction. Comprised of two layers of bleached pulp, the coated side ensures a smooth surface that is ideal for vivid printing, while the grey back serves as a sturdy foundation, providing excellent opacity. This duality not only enhances the visual appeal of printed materials but also offers a level of robustness that is crucial for packaging products.

One of the primary advantages of coated duplex board with a grey back is its environmental friendliness. Many manufacturers are increasingly focusing on sustainable practices, sourcing their materials from responsibly managed forests. This shift towards eco-conscious production resonates well with consumers who are becoming more aware of the environmental impact of their purchases.

Furthermore, the coated surface of the duplex board allows for exceptional print quality. Whether for branding, promotional materials, or packaging, the ability to showcase vibrant colors and intricate designs is crucial. This feature has led to a rise in demand among companies looking to differentiate themselves in crowded markets. The grey back adds an element of versatility, making it easier to use for various applications, from folding boxes to high-quality posters.

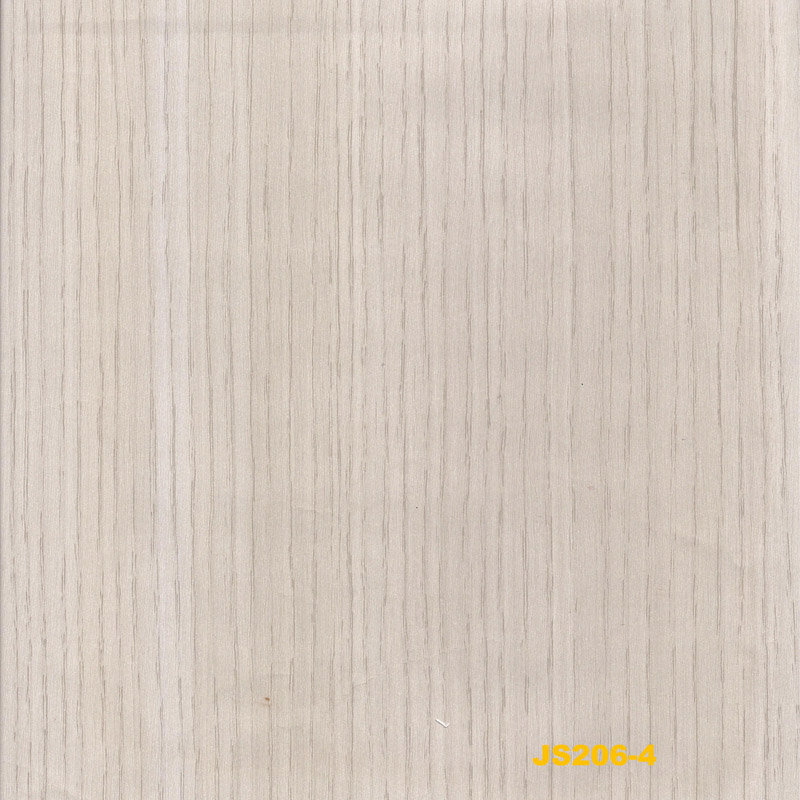

coated duplex board grey back manufacturer

Another significant benefit is the cost-effectiveness of coated duplex board. Manufacturers can produce high-quality products without the need for expensive substrates or coatings, thus passing on savings to consumers. This affordability means that businesses of all sizes can access premium materials without stretching their budgets.

In terms of usability, coated duplex board can be easily processed through various printing techniques such as litho, flexo, and digital printing. This adaptability ensures that manufacturers can meet the diverse needs of their clients, whether for short runs of promotional items or large-scale packaging solutions.

As we look to the future, the coated duplex board market continues to evolve. Innovations in coating techniques, as well as advances in sustainable practices, are paving the way for even greater applications and efficiencies. Manufacturers who embrace these changes will likely find themselves at the forefront of a thriving industry.

In conclusion, the coated duplex board with a grey back is more than just a product; it represents a harmonious blend of quality, sustainability, and cost-effectiveness. For manufacturers, leveraging this material can lead to enhanced product offerings and a competitive edge in the ever-changing marketplace. Embracing such materials not only benefits business operations but also caters to the growing demand for responsible and high-quality packaging solutions in today’s environmentally conscious world.

Latest news

-

Self Adhesive Paper for Wooden Furniture | Easy DIY Decor & Renovation

NewsAug.24,2025

-

Premium Coated Duplex Board Paper | Grey & White Back Options

NewsAug.23,2025

-

Premium Decorative Base Paper for Stylish Laminates & Panels

NewsAug.22,2025

-

Premium Decor Base Paper for Furniture & Laminates

NewsAug.21,2025

-

Easy Self Adhesive Paper for Wooden Furniture Decor

NewsAug.19,2025

-

Premium Decor Base Paper: High-Quality Melamine Impregnated Paper

NewsAug.18,2025