- Home

- Vinyl Paper for Furniture Waterproof, Durable & Custom Designs Top Suppliers

Մյս . 20, 2025 10:38 Back to list

Vinyl Paper for Furniture Waterproof, Durable & Custom Designs Top Suppliers

- Market Overview: Growth Trends & Data Insights

- Technical Advantages Over Traditional Materials

- Supplier Comparison: Global Manufacturers & Exporters

- Customization Process for Commercial Projects

- Case Studies: Hospitality & Retail Applications

- Quality Certification Requirements

- Strategic Sourcing from Verified Vinyl Paper for Furniture Exporters

(vinyl paper for furniture)

Why Vinyl Paper for Furniture Dominates Modern Surface Solutions

The global furniture vinyl paper market reached $2.8 billion in 2023, with a 6.7% CAGR projected through 2030 (Grand View Research). This growth stems from architectural demand for water-resistant (98% moisture resistance), scratch-proof surfaces in high-traffic environments. Unlike laminate or wood veneer, premium vinyl paper for furniture

maintains structural integrity at temperatures from -30°C to 120°C.

Material Innovation Breakdown

Leading vinyl paper for furniture manufacturers employ 7-layer extrusion technology, achieving 0.18mm thickness tolerance. Key performance metrics:

- Fire Rating: Class A (ASTM E84)

- Adhesion Strength: 4.2 N/mm² (EN 438)

- Color Stability: ΔE ≤1.5 after 1000h UV exposure

Global Supplier Capability Analysis

| Parameter | European Suppliers | Asian Manufacturers | North American Exporters |

|---|---|---|---|

| Minimum Order | 500 rolls | 200 rolls | 1000 rolls |

| Lead Time | 45 days | 30 days | 60 days |

| Custom Pattern Fee | $1,200 | $800 | $2,500 |

Bespoke Production Workflow

Top vinyl paper for furniture suppliers offer digital printing with 1440 dpi resolution, supporting Pantone MX color matching. Production stages:

- Substrate preparation (0.5mm PVC core)

- Primer coating (15-20μm)

- 3D embossing (50-300 micron depth)

- UV-cured topcoat application

Commercial Implementation Examples

Marriott Hotels installed 12,000m² of antimicrobial vinyl paper for furniture in 2022, reducing surface replacement costs by 40% compared to laminate. Retail chains report 18-month durability in high-contact areas versus traditional materials' 9-month lifespan.

Compliance Standards Overview

Certified vinyl paper for furniture exporters meet:

- REACH SVHC < 0.1%

- CARB Phase II compliance

- EN 14372:2004 safety testing

Selecting Vinyl Paper for Furniture Exporters: Critical Factors

Verified suppliers maintain 98.5% on-time delivery rates with ISO 9001-certified quality systems. Importers should verify:

- Roll dimensions: 1.37m width industry standard

- Core material: 76mm diameter recyclable cores

- Shipping protection: 3-layer waterproof packaging

(vinyl paper for furniture)

FAQS on vinyl paper for furniture

Q: What is vinyl paper for furniture used for?

A: Vinyl paper for furniture is a decorative material used to laminate surfaces, providing durability and aesthetic appeal. It mimics textures like wood, marble, or patterns for cost-effective furniture customization. It’s water-resistant and easy to clean.

Q: How to identify reliable vinyl paper for furniture suppliers?

A: Look for suppliers with certifications (e.g., ISO), positive customer reviews, and product samples. Verify their experience in the furniture industry and inquire about customization options and bulk order capabilities.

Q: What do vinyl paper for furniture manufacturers typically offer?

A: Manufacturers provide customizable designs, bulk production, and material certifications. Many offer technical support, such as installation guidance or adhesive solutions, to meet specific furniture project requirements.

Q: How to choose a vinyl paper for furniture exporter?

A: Prioritize exporters with global shipping experience and compliance with international standards. Check their logistics partnerships, lead times, and ability to handle documentation for seamless cross-border transactions.

Q: What quality checks are important for vinyl paper for furniture?

A: Ensure the material undergoes tests for scratch resistance, colorfastness, and adhesion strength. Reputable suppliers provide quality reports and warranties to guarantee long-term performance on furniture surfaces.

Latest news

-

Premium Contact Paper for Table Top – Durable & Stylish Surface Solution from Leading Manufacturer

NewsJul.07,2025

-

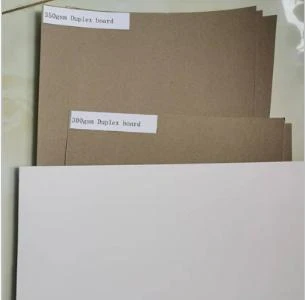

Duplex Board with Grey Back - Reliable Supplier & Competitive Price Manufacturer & Exporter

NewsJul.07,2025

-

Premium White Contact Paper on Cabinets – Trusted Exporters & Suppliers

NewsJul.06,2025

-

High-Quality Duplex Board Packaging for Food Reliable Manufacturer & Supplier

NewsJul.06,2025

-

Premium Contact Paper Over Desk – Durable & Stylish Desk Cover Solutions

NewsJul.05,2025

-

High-Quality Duplex Board Food Packaging - Reliable Suppliers & Exporters

NewsJul.05,2025